Sawtooth diaphragm, application of the sawtooth diaphragm and method for debugging light path of sawtooth diaphragm

A sawtooth and diaphragm technology, applied in the optical field, can solve the problems of difficult to observe the boundary point, low debugging efficiency, small repetition frequency laser, etc., to achieve the effect of easy observation, measurement and optical path adjustment, high debugging efficiency, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

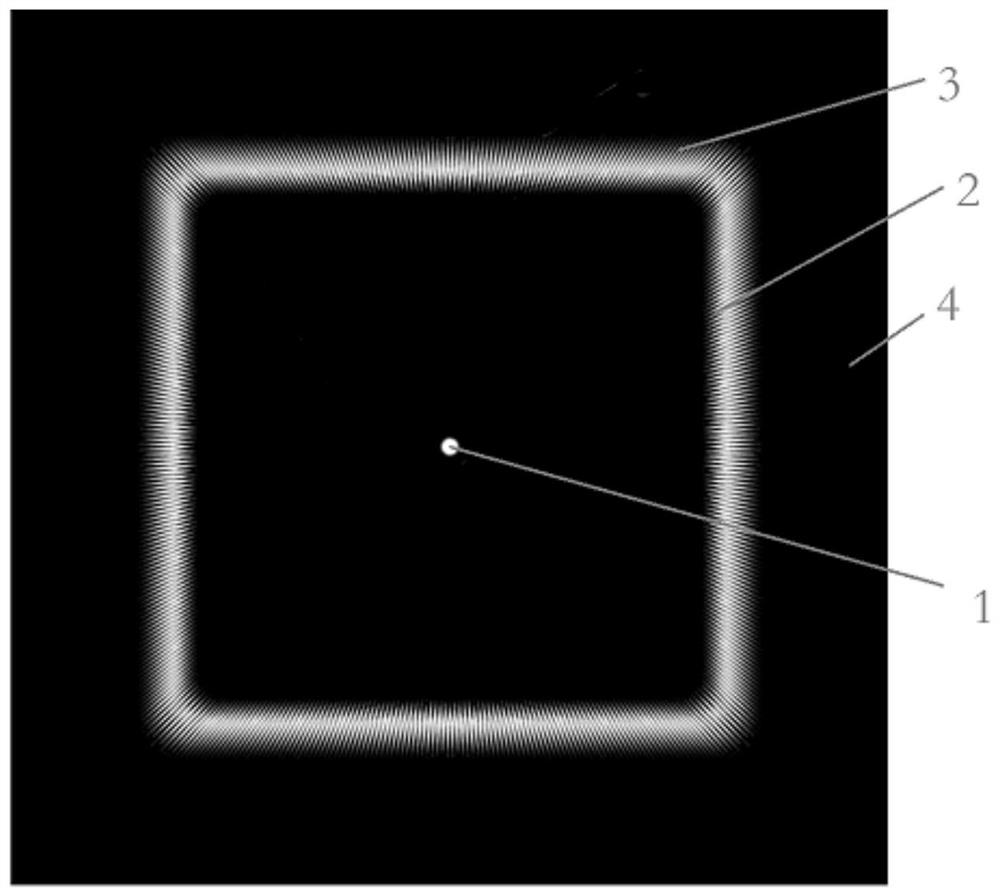

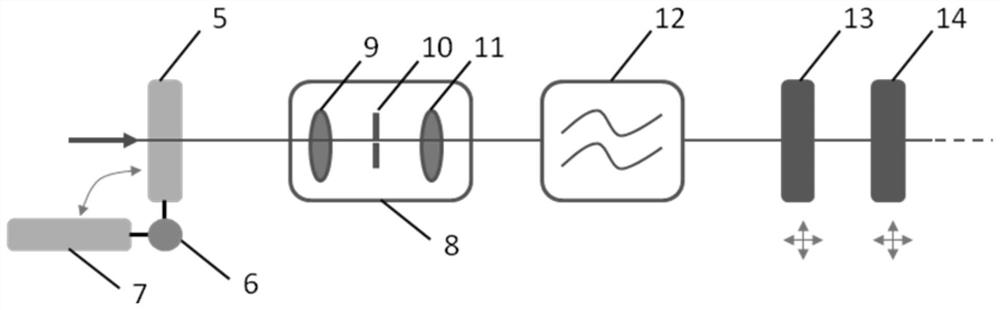

[0044] Such as figure 1 with figure 2 As shown, a sawtooth diaphragm has a circular sawtooth structure 1, a first circular sawtooth structure 2 and a second circular sawtooth structure 3 sequentially etched on the optical plane from the inside to the outside, and the circular sawtooth structure 1 is located at the center of the optical plane. center, and the first annular sawtooth structure 2 and the second annular sawtooth structure 3 take the center of the optical plane as the center, the surrounding area of the circular sawtooth structure 1, the first annular sawtooth structure 2 and the second annular sawtooth structure 3 The surrounding areas of are all light-transmitting areas, and all areas in the optical plane except the light-transmitting areas are light-opaque areas 4 . Preferably, the light-transmitting area is coated with an anti-reflection film to improve the light-transmitting effect, and the opaque area 4 is coated with a gold film to increase the laser dama...

Embodiment 2

[0056] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0057] Such as Figure 1 to Figure 3 As shown, the circumference of the circular sawtooth structure 1 is 26 times the width of the sawtooth, and the overall magnification of the laser device is 8.48 times. Processing technology, the diameter of the circular sawtooth structure 1 is 1.6 mm.

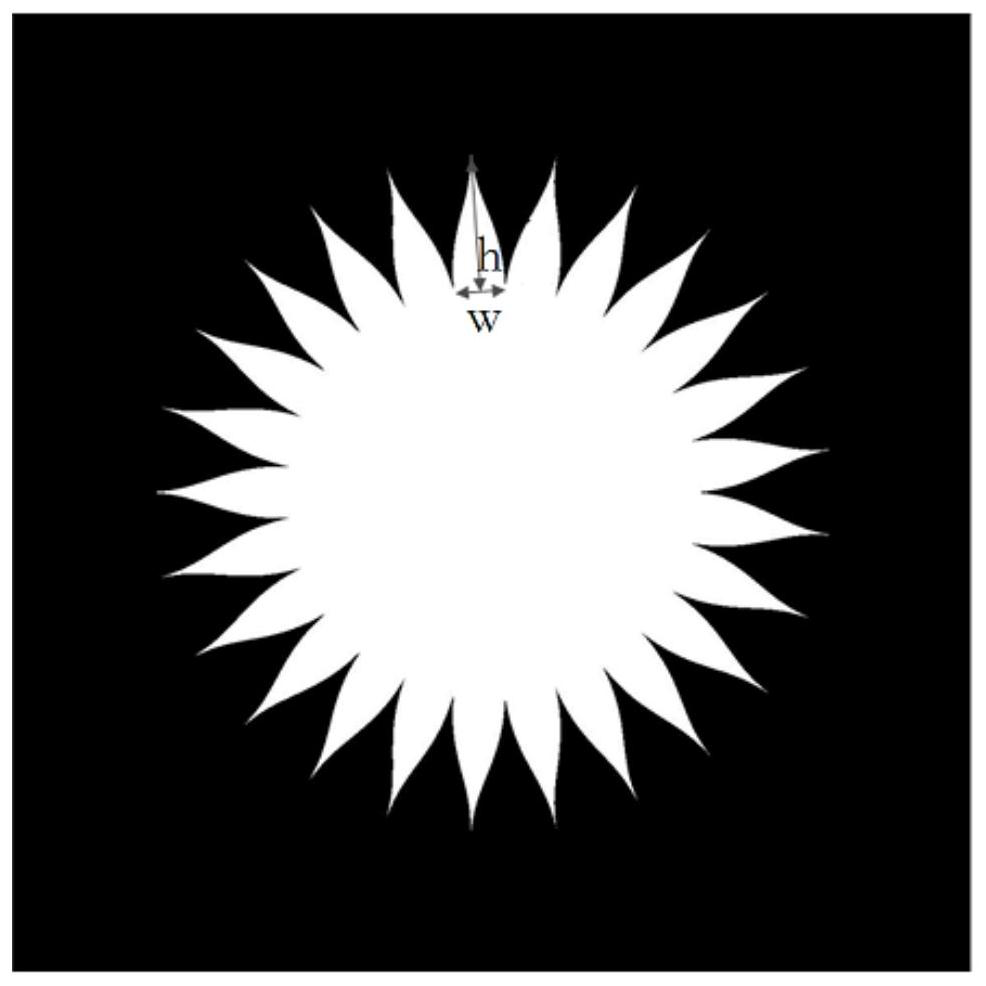

[0058] The first annular sawtooth structure 2, the second annular sawtooth structure 3, and the standard aperture 7 are all 12-order super-Gaussian distributions, and the softening factor is about 7.3%. The side length of the second annular sawtooth structure 3 and the standard aperture 7 is 48mm, and the side length of the first annular sawtooth structure 2 is 43mm. In order to make the convolution effect in the y direction significantly smaller than that in the x direction, the sawtooth width w of the circular sawtooth structure 1 , the first circular sawtooth structure 2 , and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com