Spot welder capable of welding lacquered wire directly

A technology of spot welding machine and enameled wire, which is applied in the direction of welding power supply, circuit/collector parts, welding/welding/cutting items, etc., and can solve problems such as complicated process, low work efficiency and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

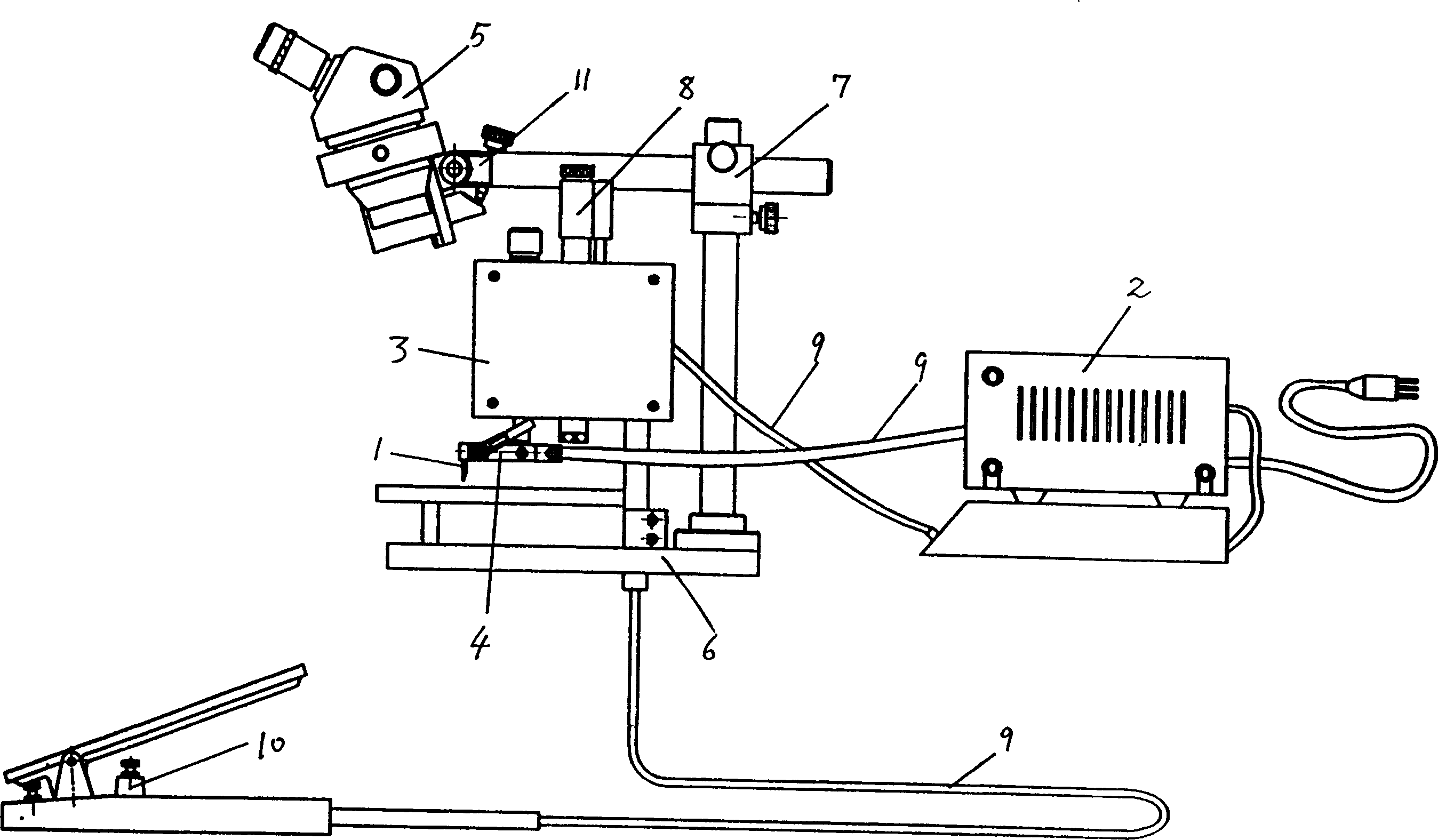

[0014] figure 1 Among them, 1 is the welding head, 2 is the main engine, which plays the role of power adjustment; 3 is the machine head, which is installed on the workbench 6, and the machine head includes the welding head clamp 4 and the welding head pressure adjustment device 8, and 5 is the microscope, which can be adjusted by angle Mechanism 11 is installed on the support 7 that is fixed on workbench 6, and 9 is connecting wire, and 10 is pedal switch.

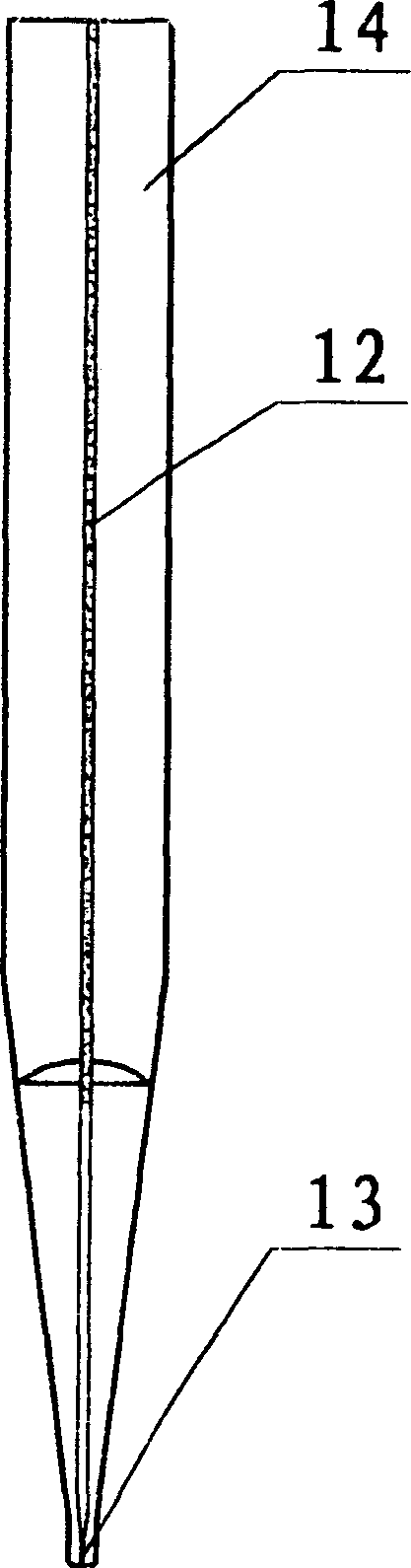

[0015] figure 2 Among them, the welding head is composed of two parallel electrodes 14 made of high-temperature-resistant metal materials, and high-temperature-resistant metal materials such as tungsten and molybdenum can be used. The ends 13 of the two electrodes are in ohmic contact with each other, and the contact resistance is generally ≤200mΩ, while other parts are insulated from each other. 12 between the two parallel electrodes can be bonded with insulating glue.

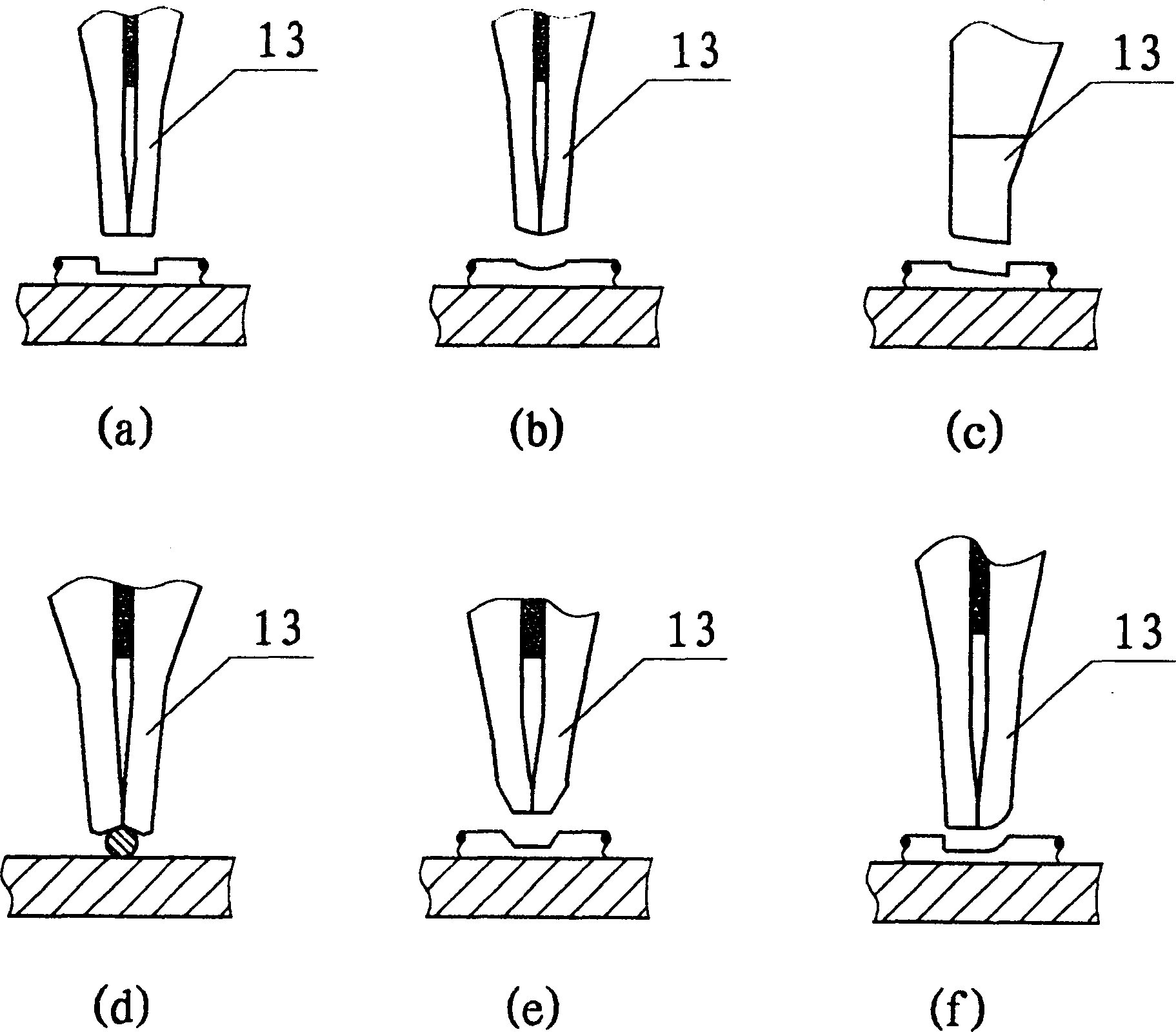

[0016] image 3 Among them, 13 is the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com