No-tillage precision-seeding and film-mulching integrated machine

An all-in-one machine and film-covering technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve problems such as shortage of labor resources, low output, burning seedlings, etc., and achieve sustainable development, improve planting efficiency, and save energy. The effect of irrigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

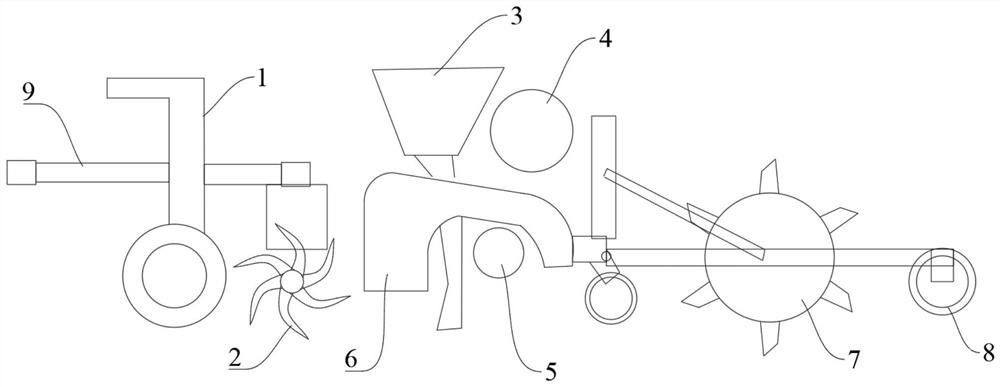

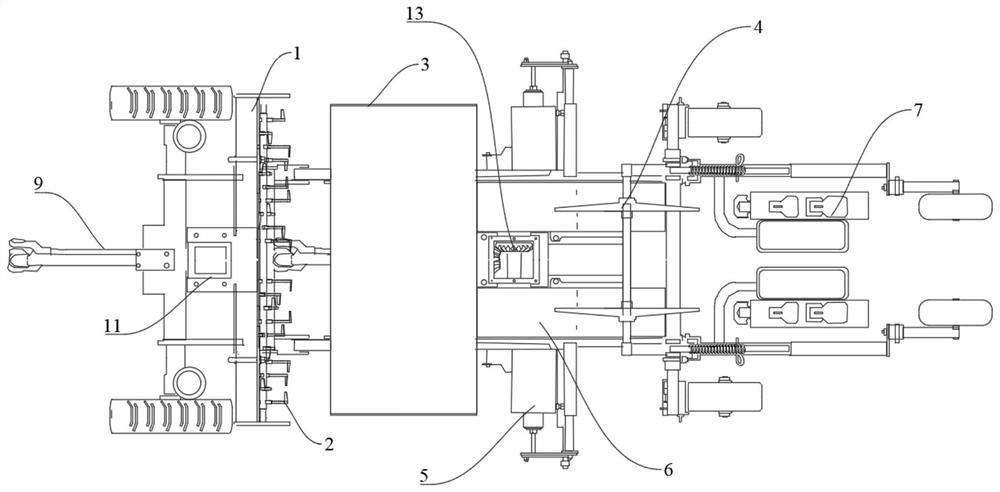

[0030] like Figure 1-Figure 2 Shown: an all-in-one machine for no-tillage precision sowing and film covering, including a frame 1, a traction device, a transmission device, a rotary tillage device 2, a fertilization device 3, and a drip irrigation belt pre-embedded device arranged on the frame 1 in sequence from front to back 4. Film covering device 5, soil covering device 6, precise sowing device 7, suppression device 8;

[0031] The traction mechanism is a traction bar connected with the frame 1, which is used to connect the tractor when the all-in-one machine is running;

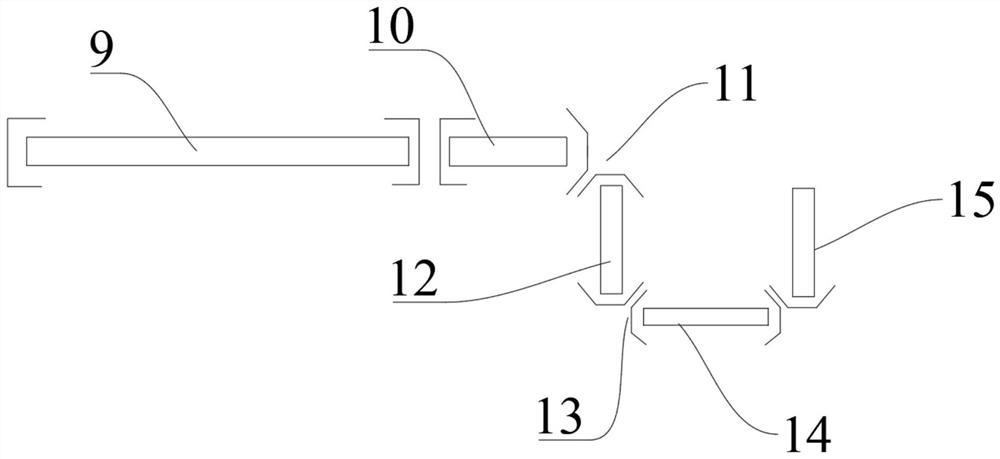

[0032] The transmission device includes a cardan shaft, a reversing mechanism, and gears, and the transmission device is used to transmit kinetic energy to the rotary tillage device 2, the fertilization device 3, and the soil covering device 6; the transmission device includes a cardan shaft 9 connected in sequence, a first intermediate transmission Shaft 10 , first reversing mechanism 11 , first power ...

Embodiment 2

[0044] Embodiment two is substantially the same as embodiment one, compared with embodiment one, its distinguishing feature is:

[0045] The frame 1 of the all-in-one machine is extended, and three rows of rotary tillage, pre-embedded fertilization and drip irrigation pipes, film covering, precision sowing, and suppression are arranged side by side to form a six-long all-in-one machine for precision sowing and film covering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com