Ultrasonic knife self-adaptive control method and system for finishing tissue shearing

An adaptive control, ultrasonic knife technology, applied in the field of medical devices, can solve problems such as surgery failure, jaw wear gasket, reduce ultrasonic knife life and other problems, to reduce tool wear, reduce operating pressure, and prolong tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

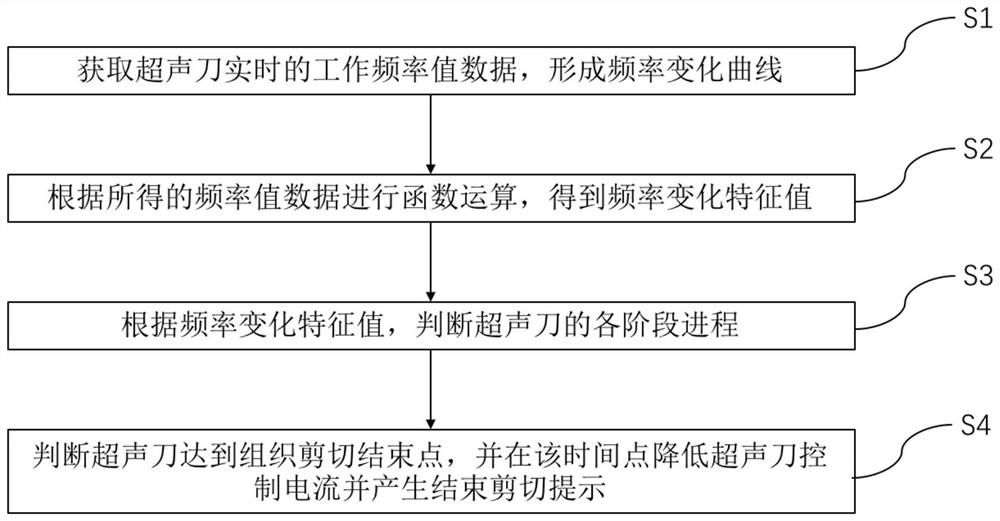

[0032] like figure 1 As shown, the present invention discloses an adaptive control method of an ultrasonic knife for ending tissue shearing, comprising the following steps,

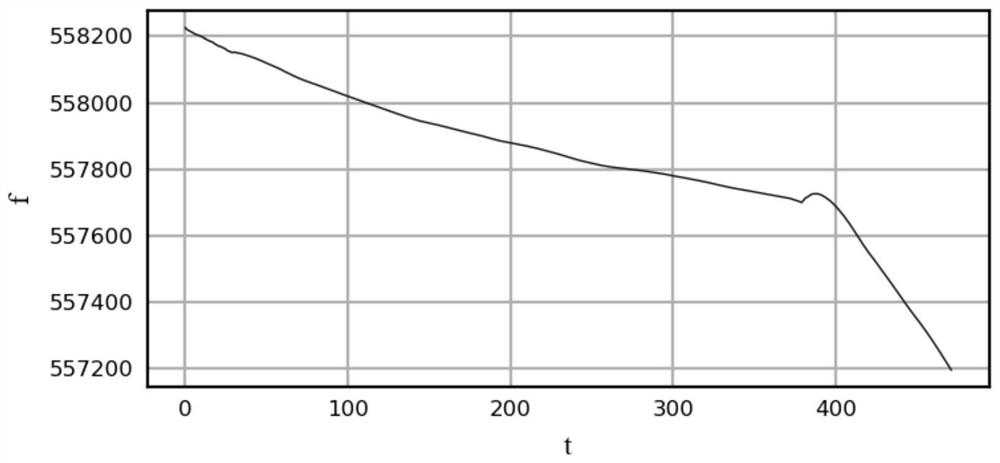

[0033] S1. Obtain the real-time working frequency value data of the ultrasonic scalpel to form a frequency change curve;

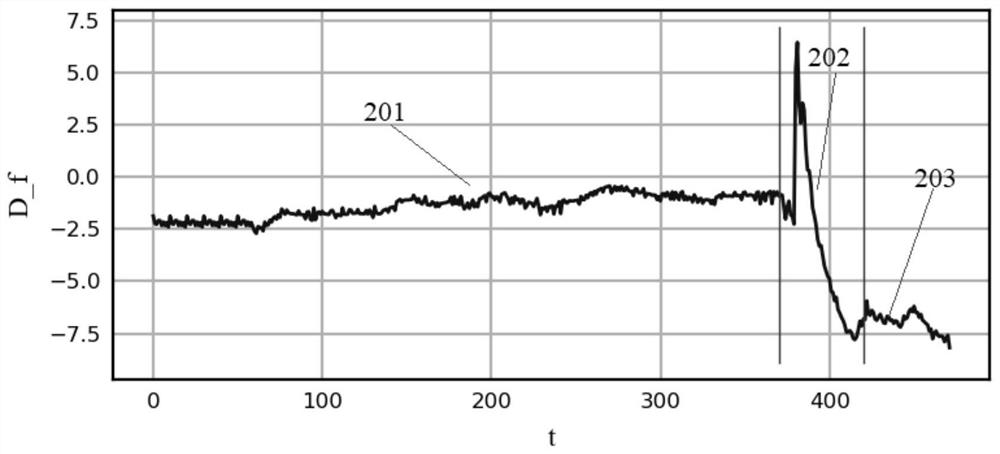

[0034] S2. Perform a function operation according to the obtained frequency value data to obtain a frequency change characteristic value;

[0035] S3. According to the characteristic value of frequency change, judge the process of each stage of the ultrasonic knife, the process at least includes the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com