Device and method for treating VOCs waste gas through activated carbon adsorption and high-temperature desorption-catalytic oxidation

A technology of activated carbon adsorption and catalytic oxidation, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of reduced adsorption activity of activated carbon, low desorption temperature of activated carbon, and many organic substances in activated carbon, so as to achieve complete desorption and guarantee Safe desorption at high temperature, the effect of increasing the desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

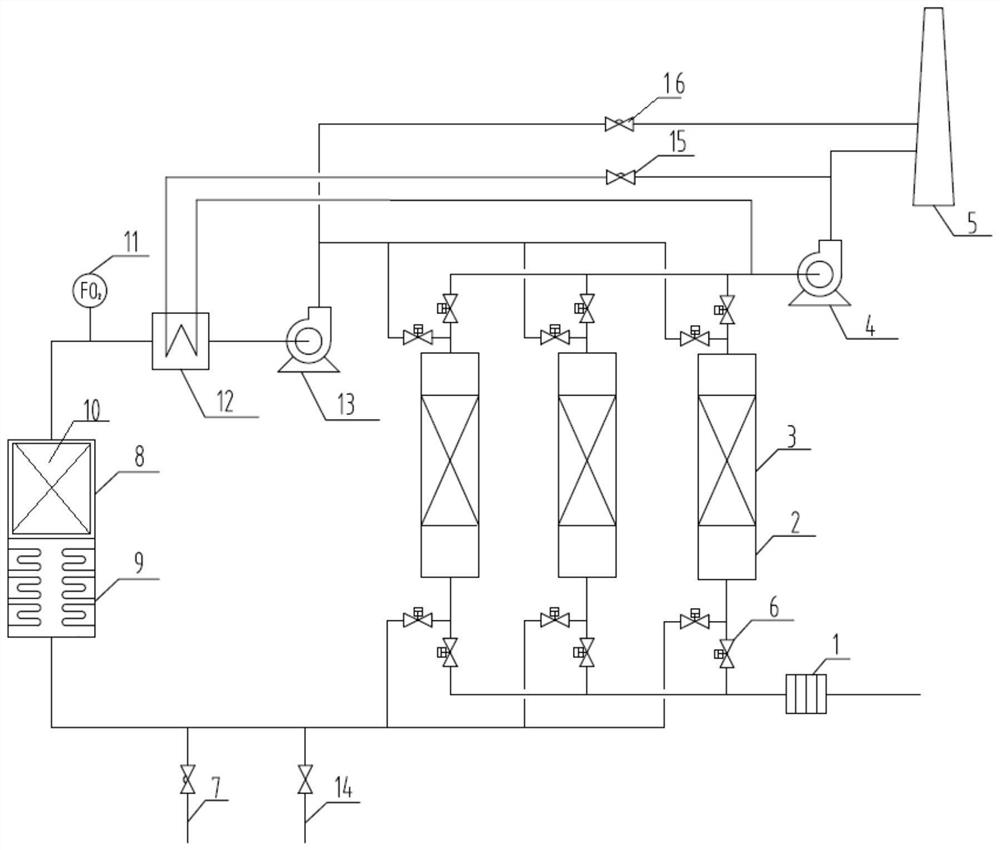

[0032] refer to figure 1 , the present invention is an activated carbon adsorption high-temperature desorption-catalytic oxidation device for treating VOCs waste gas, the device includes an adsorption system and a desorption system, and the adsorption system includes a pretreatment device 1, an adsorption unit, and an adsorption Blower fan 4 and chimney 5; Described desorption system comprises heater 9, catalytic oxidation device 8, cooling device 12, desorption blower fan 13 that are arranged according to desorption order, and described catalytic oxidation device 8 is provided with catalyst 10, described The inlet of the catalytic oxidation device 8 is connected to the adsorption unit with the outlet of the desorption fan 13, and a nitrogen purging device 14 and an oxygen supply device 7 are successively arranged between the adsorption unit and the inlet of the catalytic oxidation device 8 according to the desorption sequence, The oxygen supply device 7 is used to replenish f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com