Secondary water supply pipeline cleaning device

A secondary water supply and cleaning device technology, applied to water supply devices, water supply main pipelines, general water supply conservation, etc., can solve problems such as narrow operating space, waste of manpower and material resources, and inability to clean pipes, so as to achieve no chemical pollution and reduce power sources The effect of the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

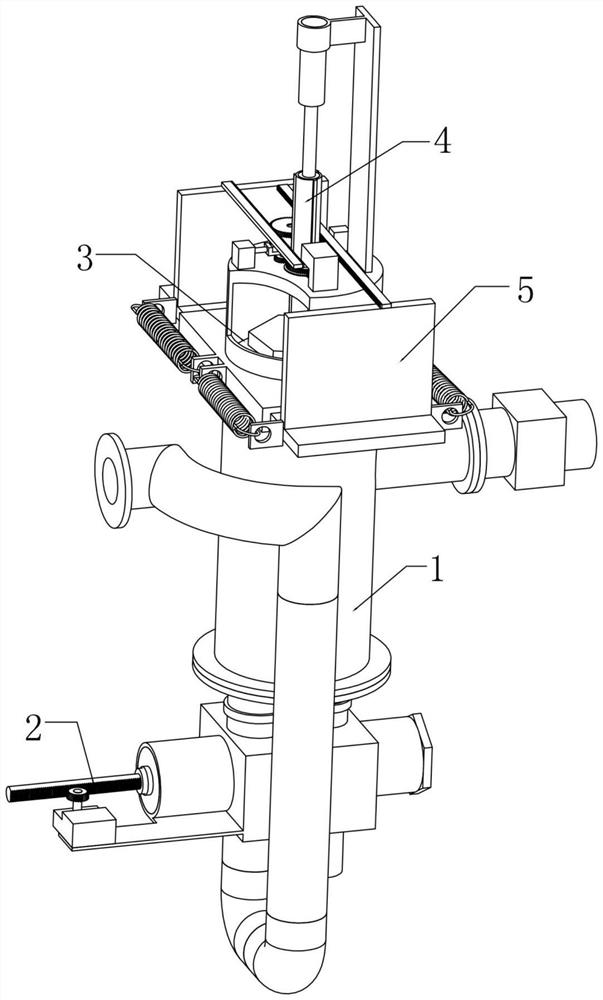

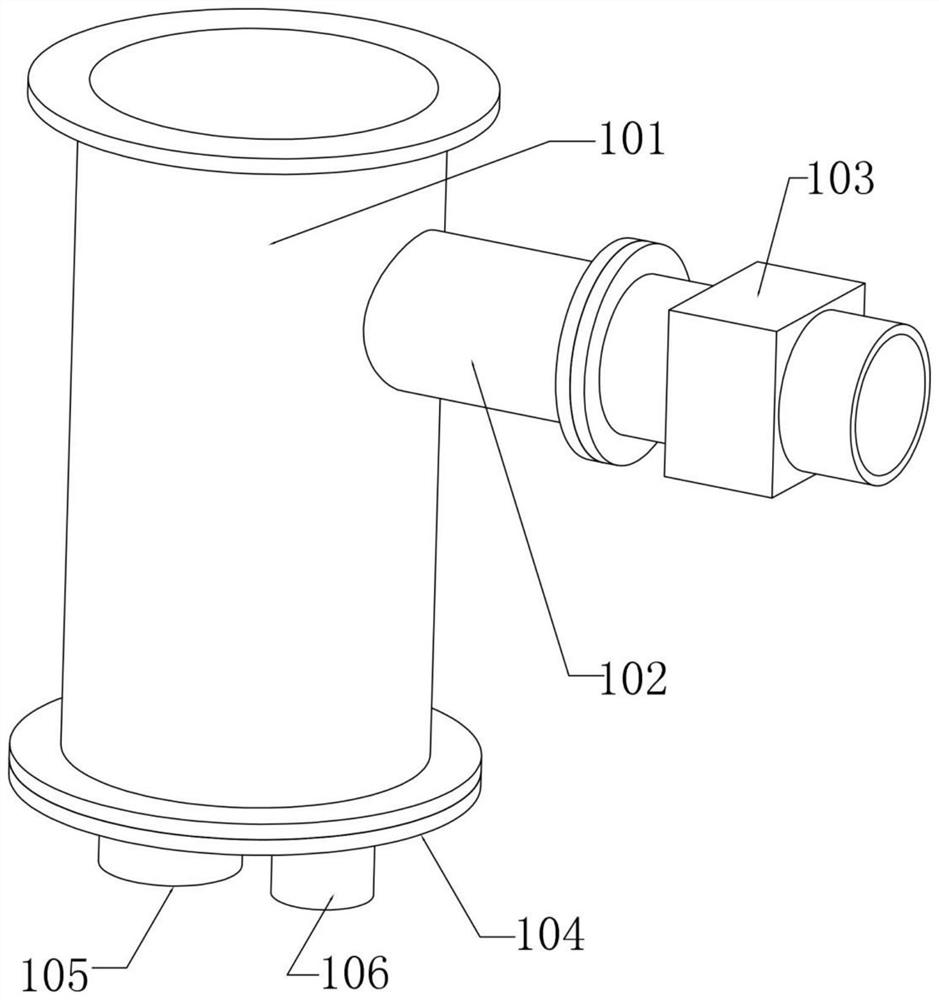

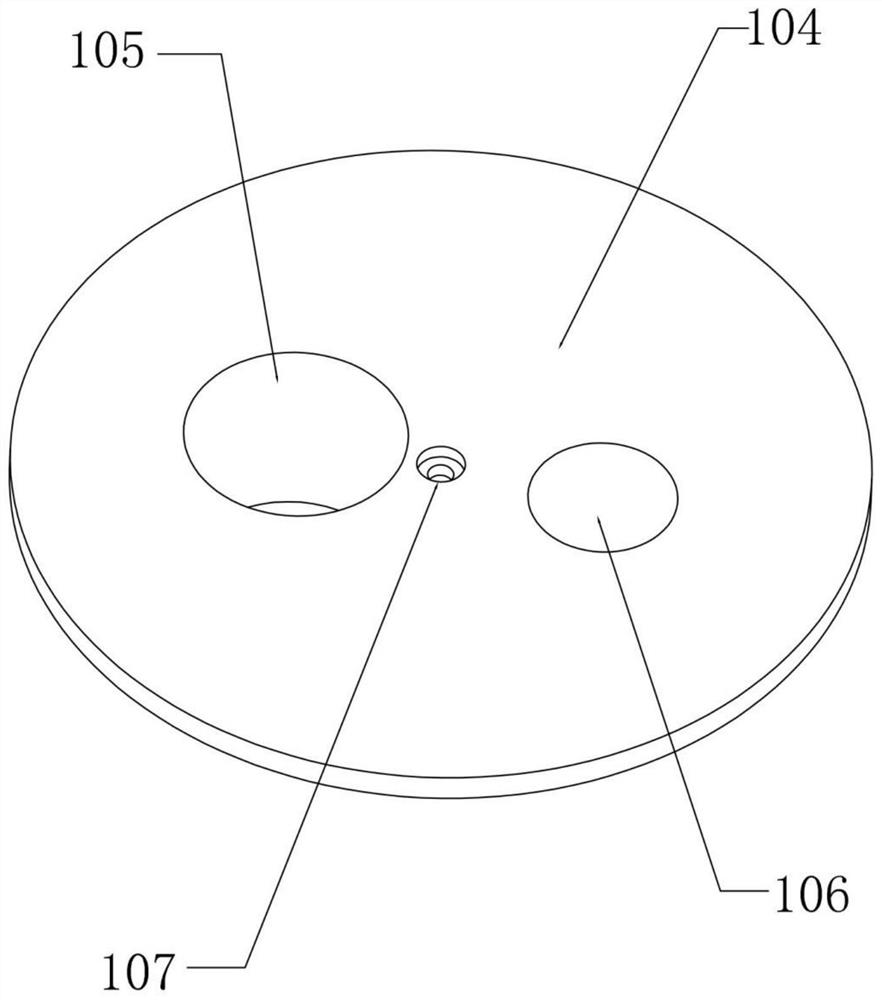

[0043] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 12 , Figure 13 , Figure 14 , Figure 15 In the shown secondary water supply pipe cleaning device, the main cylinder 101 in the cylinder assembly 1 is the main body of the device, the switching valve body 201 in the switching valve assembly 2 is arranged at the bottom of the main cylinder 101, and the cleaning assembly 3. The array of telescopic seats 305 is located inside the cavity of the main cylinder 101. Brushes 318 are evenly arranged on the outer cylindrical surface of the telescopic seats 305. The upper cover 402 in the cleaning linkage assembly 4 is fixedly installed on the main cylinder 101. The top and both sides of the lower part of the upper cover 402 are respectively provided with cover insertion positions 410, and the two sets of cover plates 501 in the cleaning cover assembly 5 are respectively inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com