Production process of automobile compressor

A production process and compressor technology, which is applied in the production process field of automotive compressors, can solve the problems of slow manual clamping speed, increased production cost, and increased production cost, so as to improve production efficiency and yield, and ensure high Yield molding, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

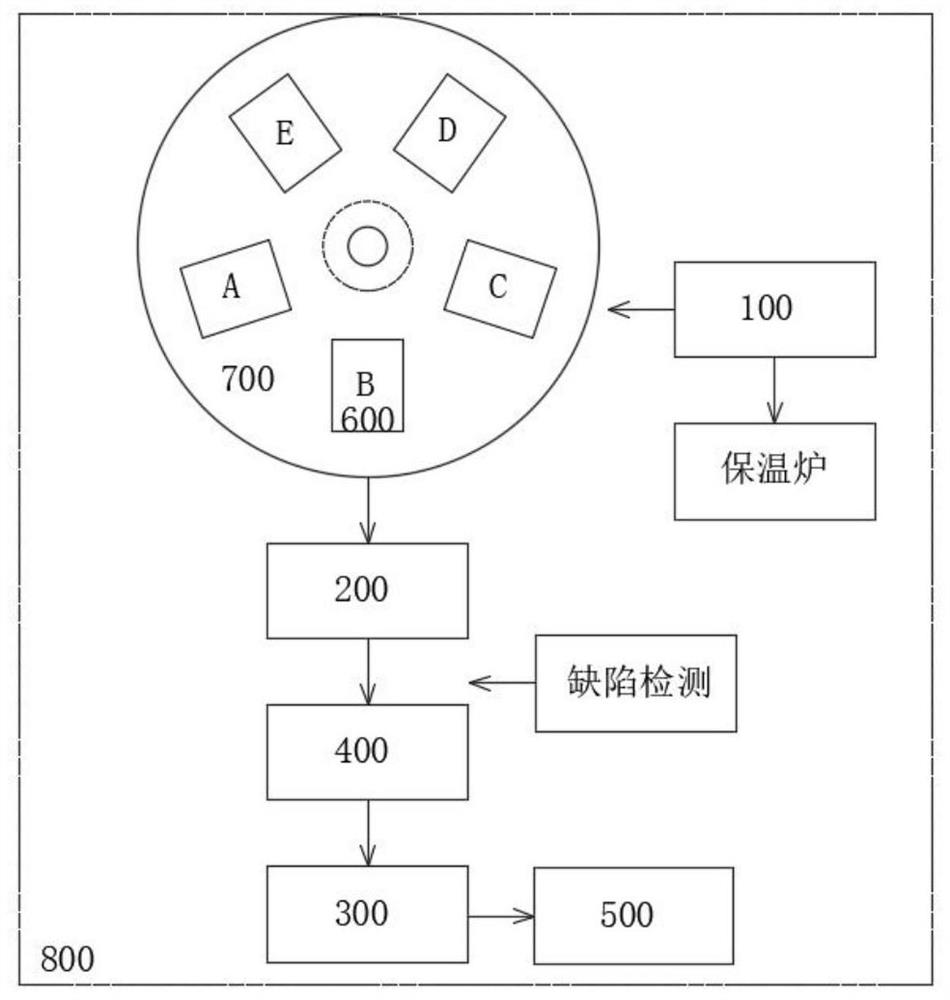

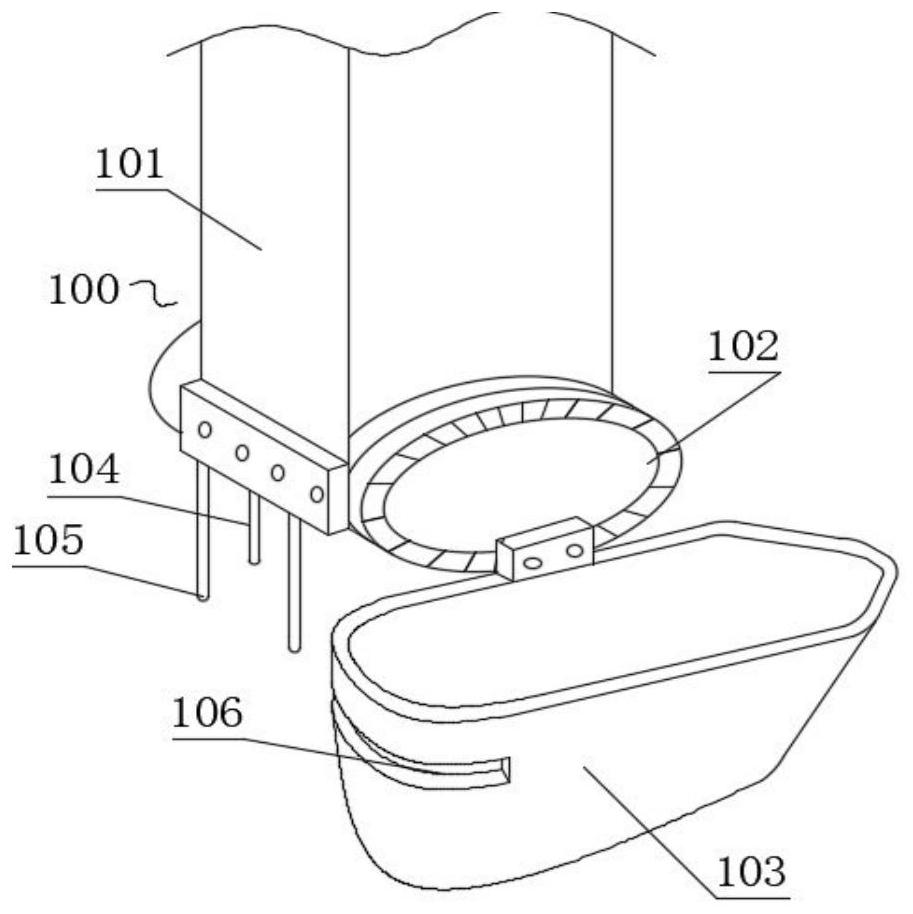

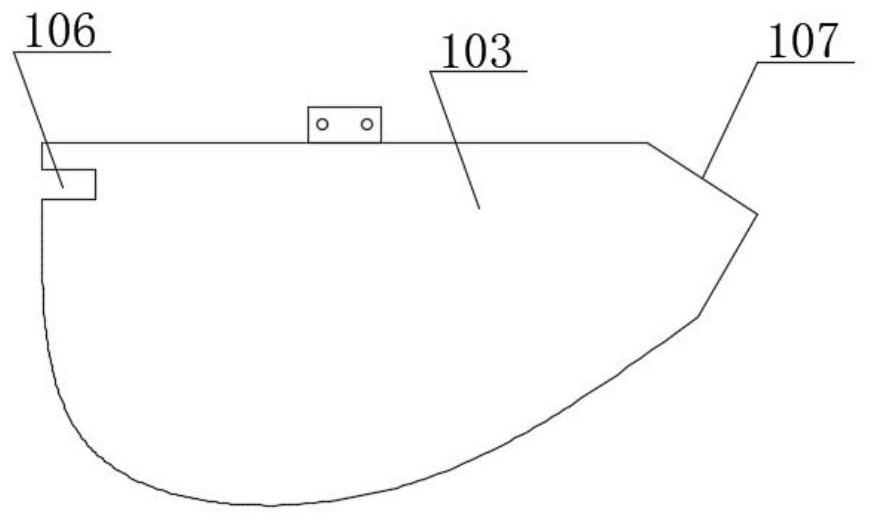

[0071] Example: such as figure 1 As shown, a production system for automotive compressors includes a working platform 700 with a driving device, and five molds installed on the working platform 700 at equal intervals and located at different stations (A, B, C, D, E) Component 600, a casting device 100 for casting molten aluminum into the mold component 600, a pick-and-place device 200 for clamping the molded blank inside the mold component 600, a cooling device 400 for embrittlement of the molded blank, The pick-and-place device 2 300 for gripping the cooled blank, the trimming device 500 for trimming the cooled blank, the driving device for controlling the working platform 700, the mold assembly 600, the pick-and-place device 1 200, the pick-and-place device The control system 800 of the device two 300 , the cooling device 400 and the trimming device 500 . The mold assembly 600 is an existing mold and has a controllable cooling structure during the molding process and a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com