Lithium oxide centrifugal bead-making method and device

A lithium oxide and supply device technology, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve problems such as difficult steady-state operation, difficult particle size control, and low density of ceramic microspheres, so as to avoid design and Difficulty in processing, universal and economical, and the effect of increasing the scale of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

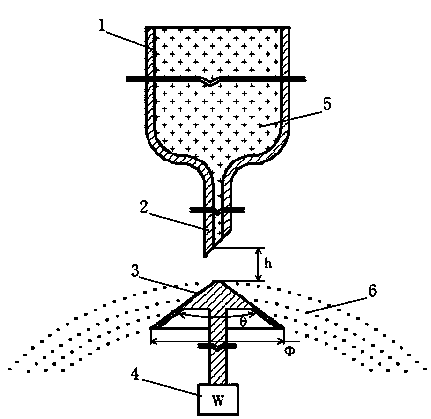

[0037] A kind of centrifugal ball making method of lithium oxide, comprises the steps:

[0038] (a) dripping or flowing molten or slurry lithium oxide onto a rotating disk;

[0039] (b) Lithium oxide flies away from the shaft disc under the action of centrifugal force to form small balls;

[0040] (c) Use refrigerant to collect, cool and fix the pellets.

[0041] The lithium oxide is Li 2 O. Li 4 SiO 4 , Li 2 TiO 3 , Li 2 ZrO 3 , LiAlO 2 Lithium-containing oxides and other oxides are prepared according to existing processes. After the lithium oxide in the molten state or the lithium oxide in the slurry state in this embodiment is dropped or flowed onto the shaft disk, after being scattered by the centrifugal force of the shaft disk, it shrinks into a ball by the surface tension, and then the cooling medium is used to Collect, cool and fix to form, and obtain lithium oxide pellets. If it is lithium oxide in a molten state, the target pellet product will be obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com