Method for analyzing injection molding process capability by using data of sensor in injection mold cavity

A technology for injection mold cavity and capability analysis, which is applied in the field of injection molding process capability analysis using sensor data in the injection mold cavity, which can solve problems such as time-consuming and labor-intensive, and achieve the effect of improving statistical efficiency and reducing human error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

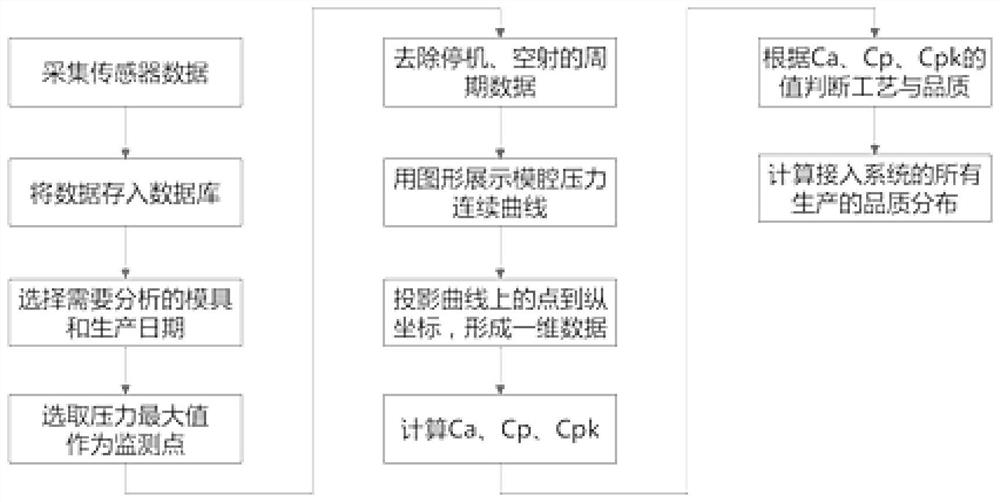

[0054] Such as Figure 1-9 As shown, the method for analyzing the capability of the injection molding process by using the sensor data in the injection mold cavity includes the following steps:

[0055] Step 1: Install a pressure sensor near the gate of the mold, and collect raw data from the sensor in tabular form;

[0056] Step 2: Store the collected data into the database;

[0057] Step 3: Select the mold and production date to be analyzed;

[0058] Step 4: Select the maximum pressure as the monitoring point;

[0059] Step 5: Remove the periodic data of shutdown and air launch;

[0060] Step 6: Graphically display the continuous curve of cavity pressure;

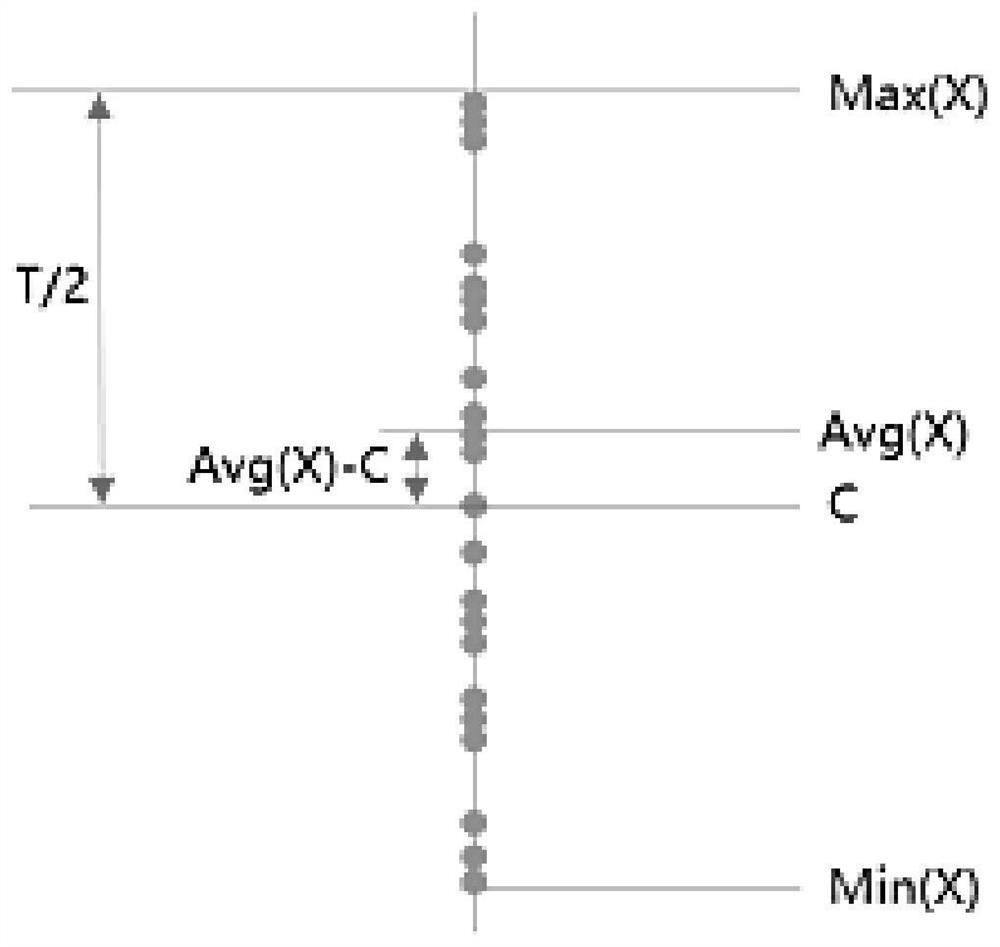

[0061] Step 7: Project the points on the curve to the ordinate to form one-dimensional data;

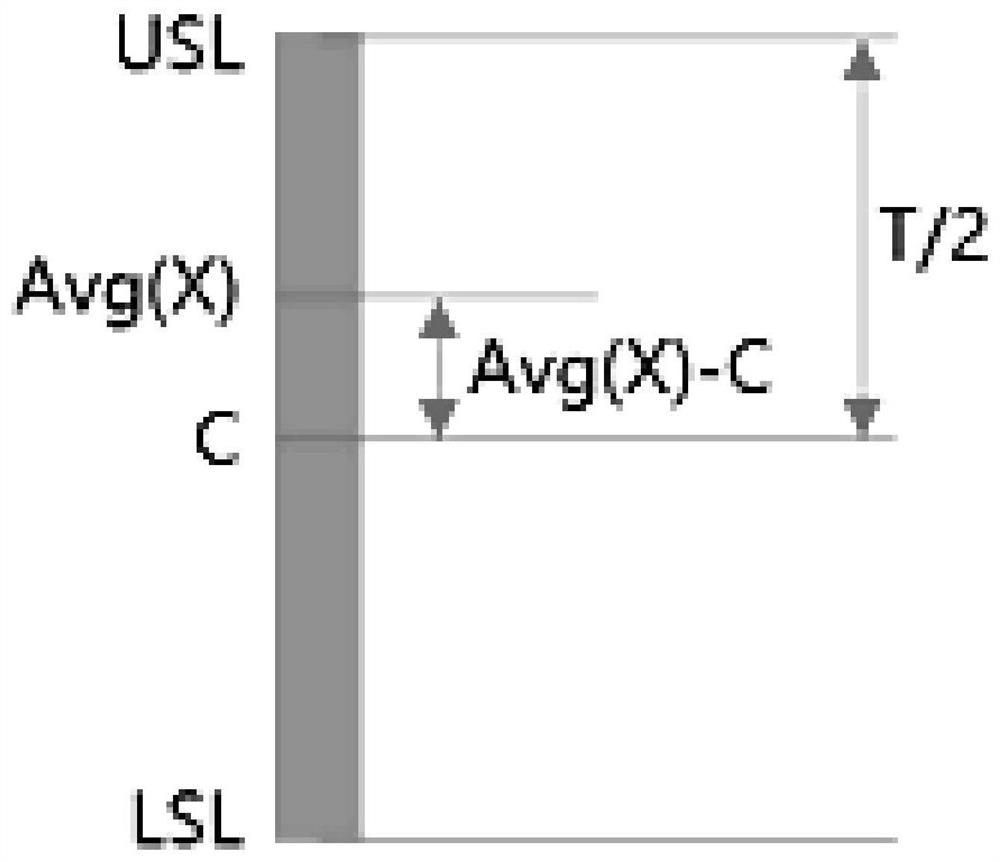

[0062] Step 8: Calculate Ca, Cp, Cpk;

[0063] Step 9: Judge the process and quality according to the values of Ca, Cp, and Cpk;

[0064] Step 10: Calculate the quality distribution of all productions connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com