Manufacturing method of light-emitting car logo mask

A manufacturing method and mask technology, applied to vehicle parts, printing post-processing, printing devices, etc., can solve the problems of increased system cost, low yield rate, and complicated system process path, so as to reduce manufacturing cost and space Excellent effect of thickness and astigmatism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for manufacturing a luminous vehicle logo mask, comprising the following steps:

[0046] Step 1. Set an ink pattern layer by screen printing on the IML diaphragm, plate a nano-metal coating by PVD vacuum sputtering method, and set an astigmatism ink layer by screen printing; the ink pattern layer is the same as the pattern of the car logo of the main engine factory;

[0047] The IML diaphragm is divided into A and B surfaces, the A surface is the bonding surface with the mask injection molding material, and the B surface is the exposed surface;

[0048] The process sequence of the ink pattern layer, the nano-metal coating and the astigmatism ink layer includes the following six schemes:

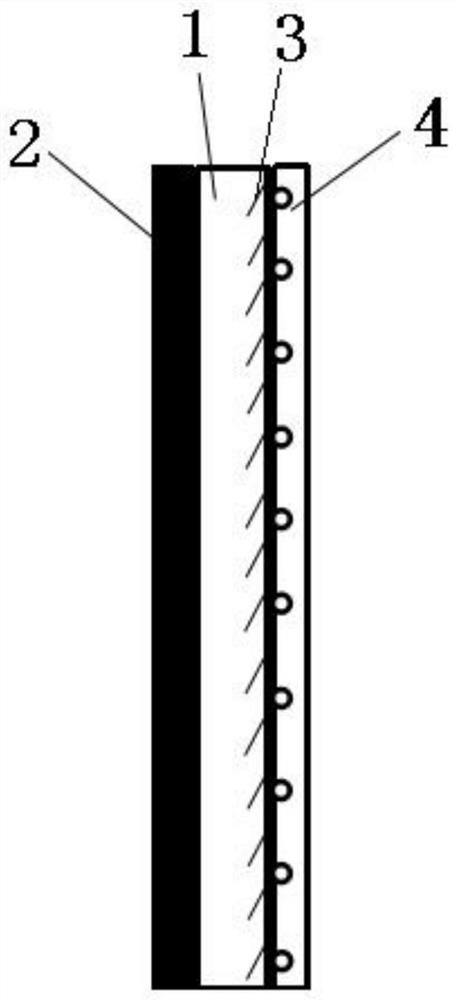

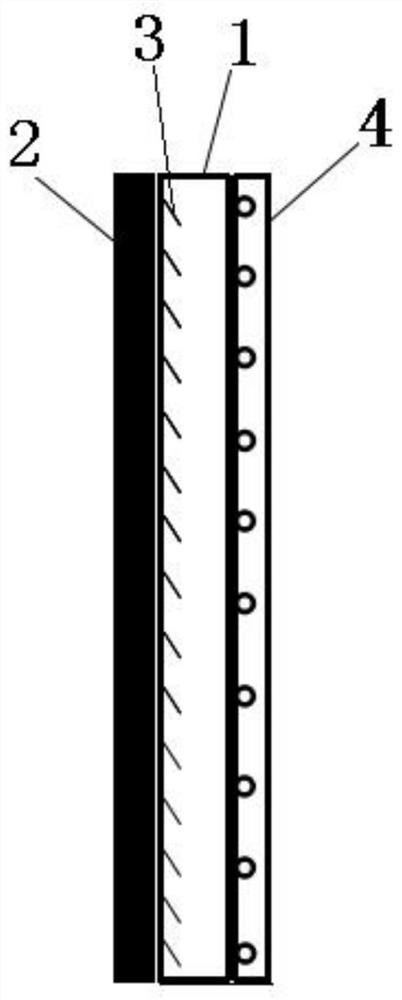

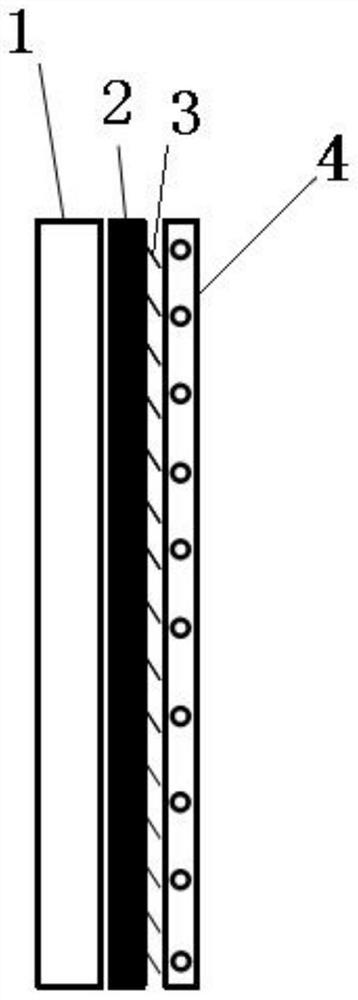

[0049] Such as figure 1 As shown, the process sequence of the IML diaphragm 1 with ink pattern layer 2, nano-metal coating 3 and astigmatism ink layer 4 produced by scheme 1 is as follows: first, nano-metal coating 3 is plated on surface B, and then Screen printing ink patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com