Needle mushroom liquid strain culture tank

A technology of liquid strains and culture tanks, which is applied in the direction of sterilization method, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of uneven culture quality of Flammulina velutipes liquid strains Nutrient solution can not be fully mixed, lack of visual operation interface and other problems, to achieve the effect of reducing the possibility of bacterial contamination, high practical value, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

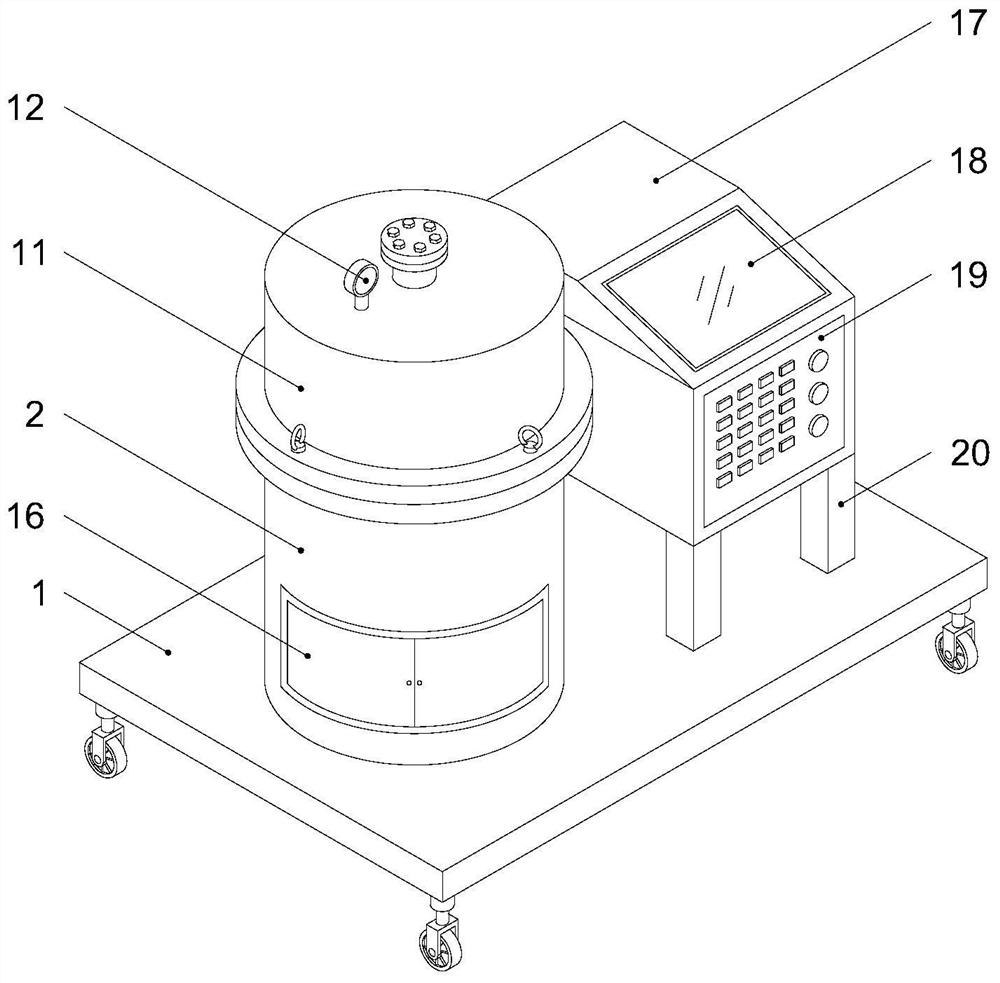

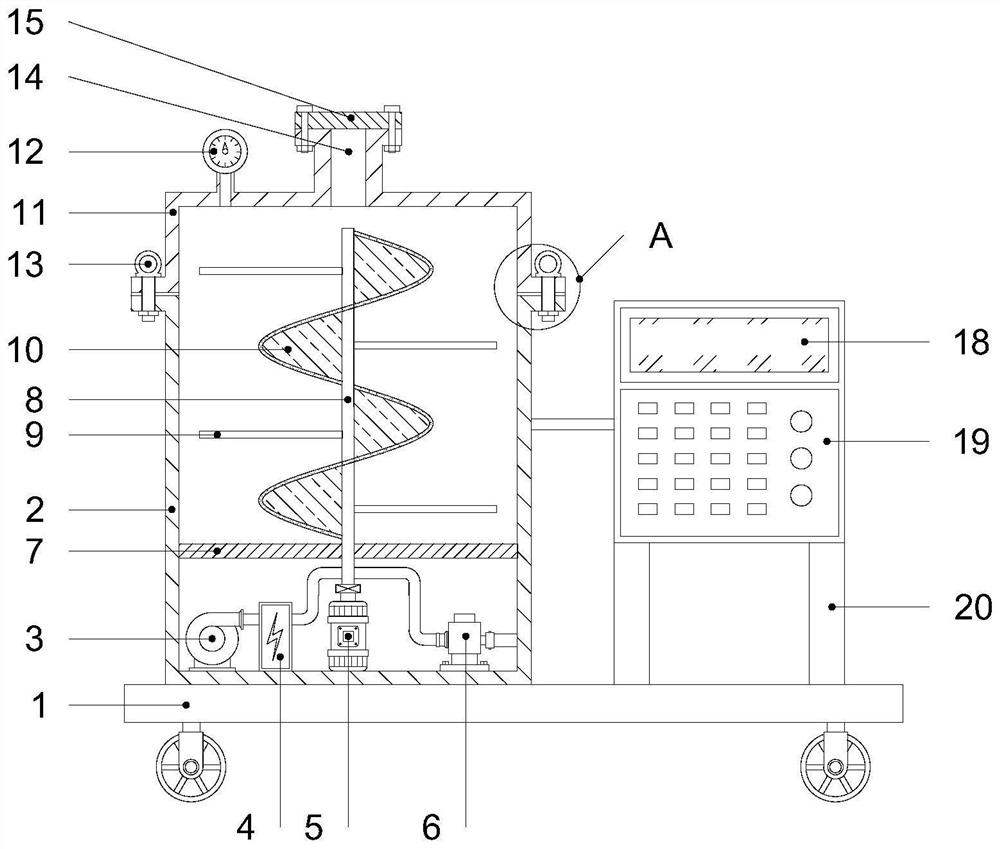

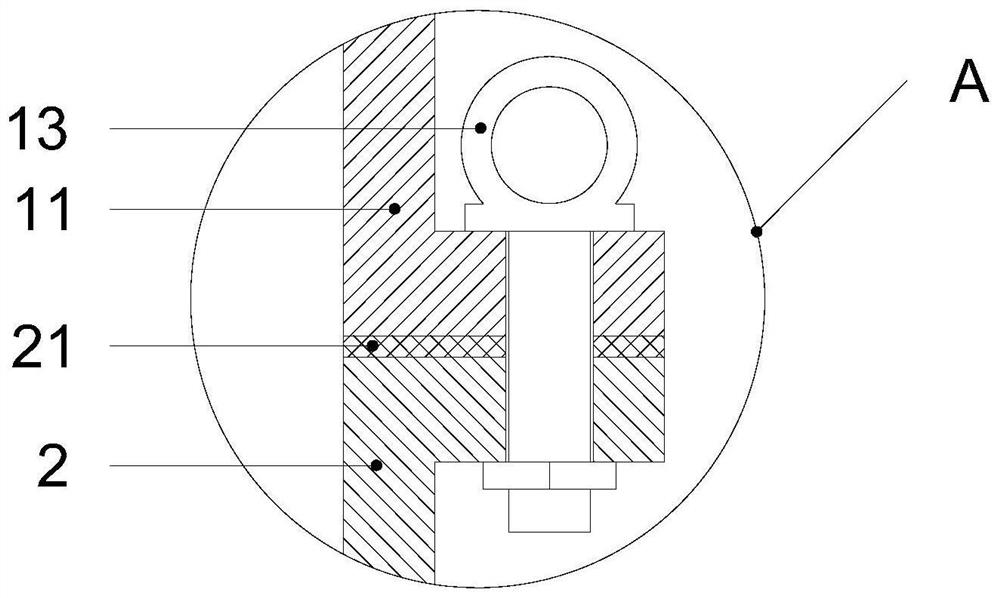

[0020] Example: such as Figure 1-3 Shown, a kind of Flammulina velutipes liquid strain cultivation tank of the present invention comprises a base plate 1, a tank body 2 is fixedly installed on one side of the top of the base plate 1, an air pump 3 is fixedly installed on the inner bottom side of the tank body 2, and an air pump 3 is fixedly installed on one side of the air pump 3. The temperature controller 4, the temperature controller 4 is fixedly installed with a motor 5 on the side away from the air pump 3, the motor 5 is fixedly installed with a water pump 6 on the side away from the temperature controller 4, and the inside of the tank body 2 is fixed on the top near the water pump 6 A partition 7 is installed, and a rotating shaft 8 runs through the interior of the partition 7, and one end of the rotating shaft 8 is connected to the output shaft of the motor 5 through a coupling transmission. A number of water pipes 9 are fixedly installed in the gap, and a tank cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com