Construction technology for high-jet grouting body built-in prestressed concrete pile

A construction technology and prestressing technology, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of inconspicuous reinforcement effect and poor bearing capacity, so as to reduce project cost, improve pile side resistance, and adaptability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

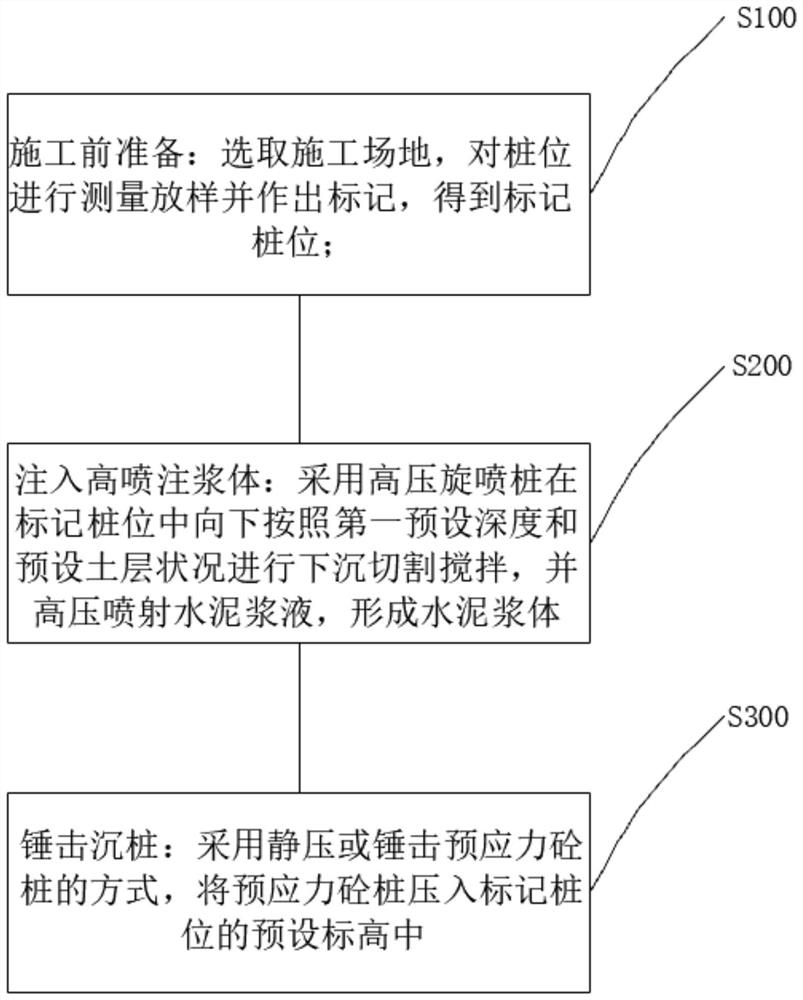

[0042] Please refer to figure 1 , the present embodiment provides a construction process of prestressed concrete piles with built-in high-spray grout, which includes the following steps:

[0043] The embodiment of the present application provides a construction process of prestressed concrete piles with built-in high injection grout, including the following steps:

[0044] S100, preparing before construction, selecting a construction site, measuring and setting out pile positions and marking them, to obtain marked pile positions;

[0045] S200, inject high-jet grout, use high-pressure rotary grouting piles to sink, cut and mix downwards in the marked pile position according to the first preset depth and preset soil layer conditions, and spray cement grout at high pressure to form cement grout;

[0046] S300, sinking piles by hammering, adopts the method of static pressure or hammering prestressed concrete piles, and presses the prestressed concrete piles into the preset eleva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com