TBM cutter head and TBM

A technology for roadheaders and cutterheads, which is applied in mining equipment, earth-moving drilling, tunnels, etc., can solve problems such as difficulty and self-importance of abrasives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

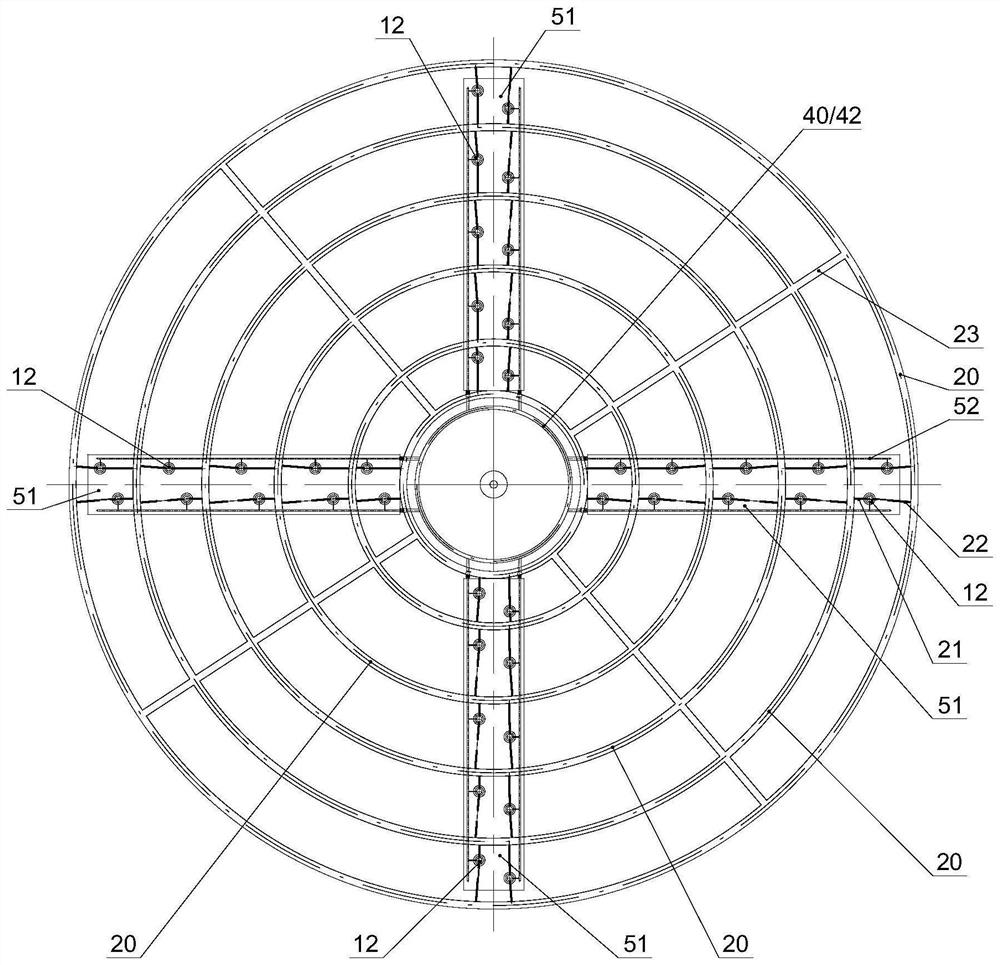

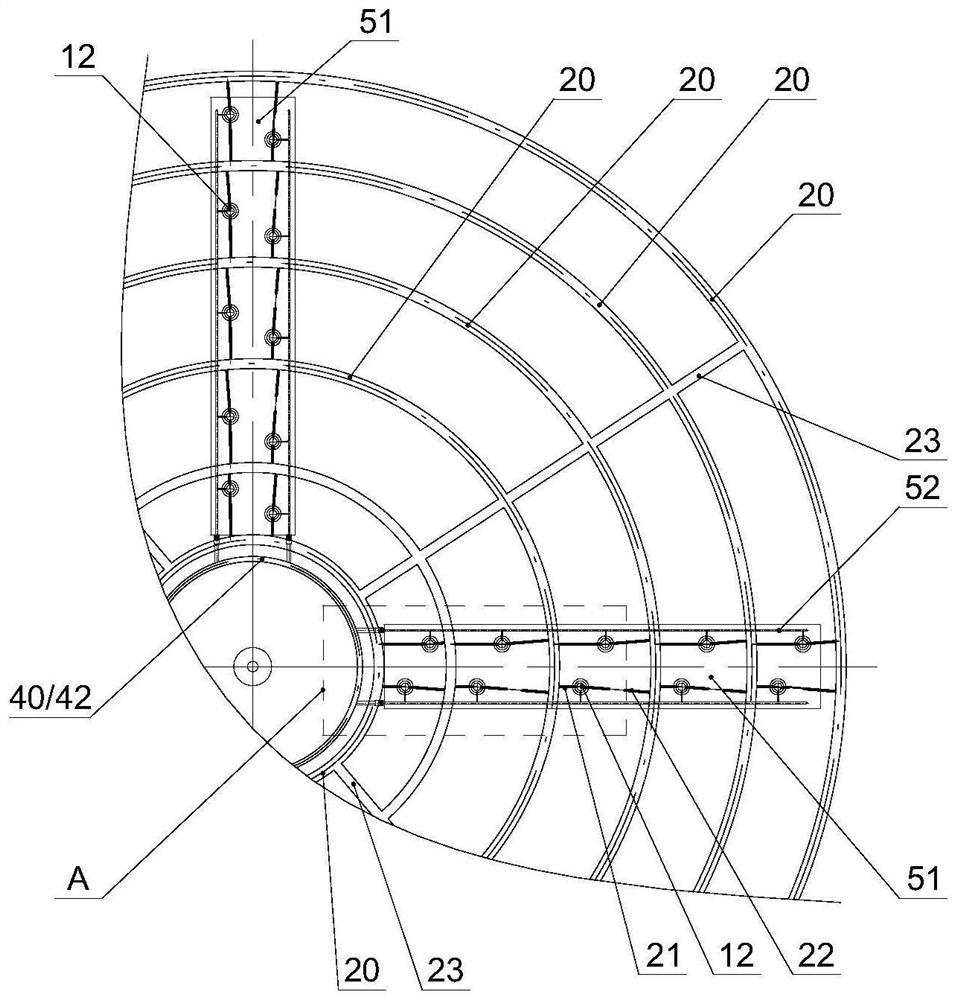

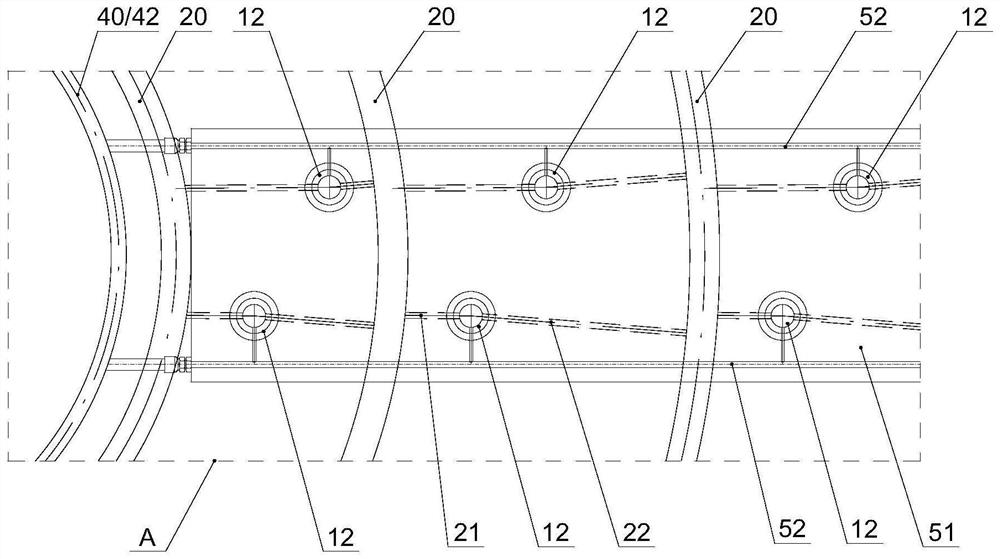

[0040] The present invention provides a TBM cutter head, such as Figure 1-Figure 6 and Figure 8 As shown, the TBM cutterhead includes: cutterhead disc body 11, nozzle 12, water supply mechanism 40, annular abrasive pipe 20, and abrasive material supply device 30, nozzle 12, water supply mechanism 40 and annular abrasive pipe 20 are all installed on the knife Disc body 11; a plurality of annular abrasive tubes 20 are arranged inside and outside, for the abrasive device 30 to communicate with each annular abrasive tube 20, for supplying abrasives for each annular abrasive tube 20; the water supply mechanism 40 communicates with the nozzle 12 , used to supply high-pressure water to the nozzle 12; the nozzle 12 is arranged between the annular abrasive pipes 20, the nozzle 12 communicates with the annular abrasive pipe 20 on the outside through the outer abrasive passage 22, and the nozzle 12 communicates with the inner abrasive passage 21 and the inner ring Abrasive tube 20 com...

Embodiment 2

[0055] The present invention provides a TBM roadheader, comprising: a body of the roadheader and the above-mentioned TBM cutterhead, wherein the TBM cutterhead is installed on the body of the roadheader.

[0056] The TBM tunnel boring machine uses an abrasive jet to cut deep grooves into the rock surface. After the rock is cut into deep grooves, the rock is peeled off under the action of the hob on the TBM cutterhead. The deep groove can greatly reduce the difficulty of rock breaking by the hob and play an auxiliary role in rock breaking. Moreover, during the rotation of the TBM cutter head, no matter where the nozzle 12 is at any position relative to the center of the cutter head, it can always be guaranteed that there is at least one annular abrasive tube 20 higher than / not lower than the nozzle 12, thereby ensuring at least one annular abrasive tube 20. The abrasive in the abrasive pipe 20 can flow smoothly to the nozzles 12, ensuring that the abrasive is continuously supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com