Stator assembly of electronic water pump

An electronic water pump and stator assembly technology, which is applied to pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve the problems of vehicle safety, inoperability, hidden dangers, etc., to solve potential safety hazards, Effect of improving heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

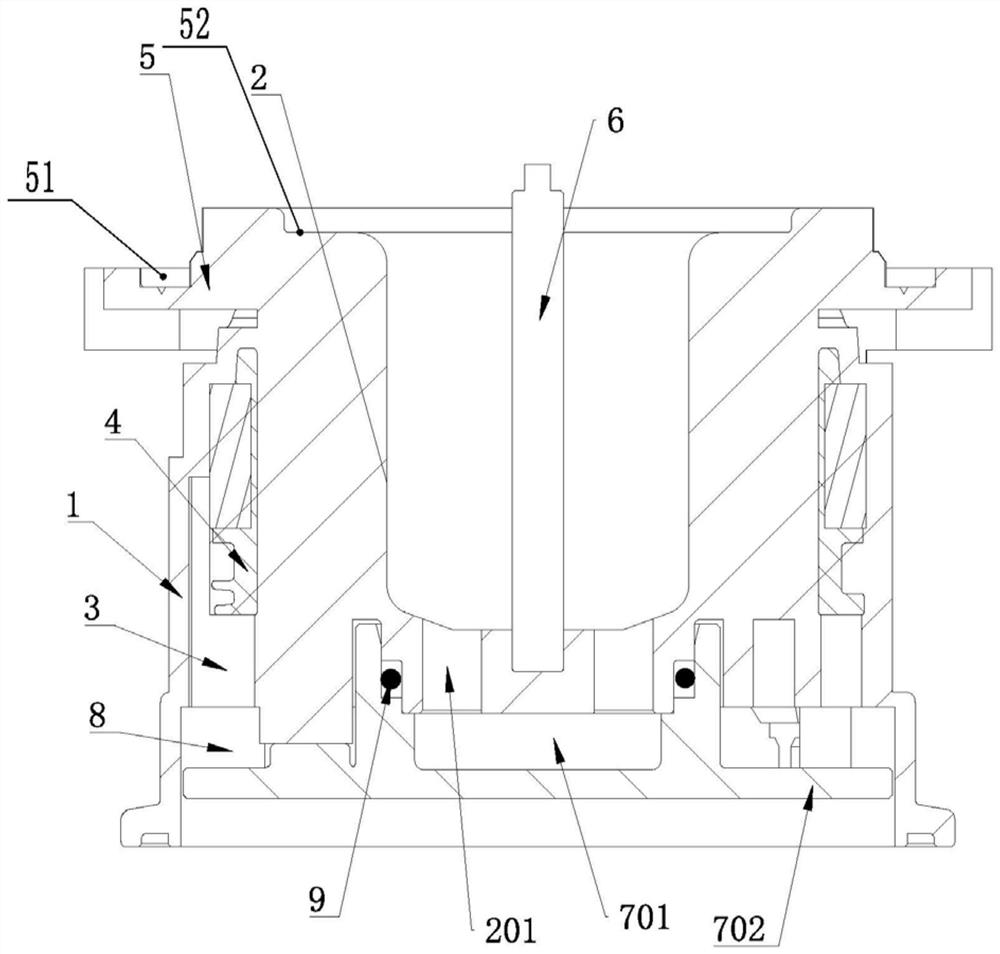

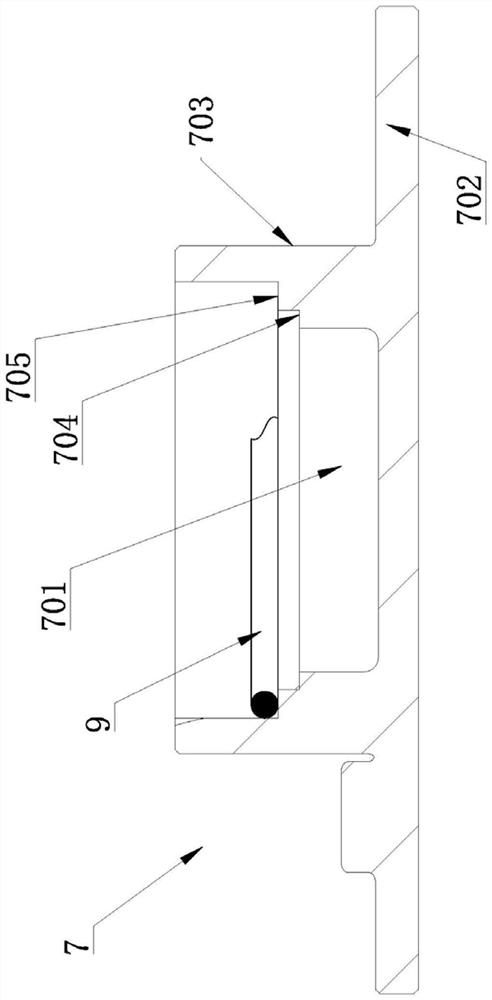

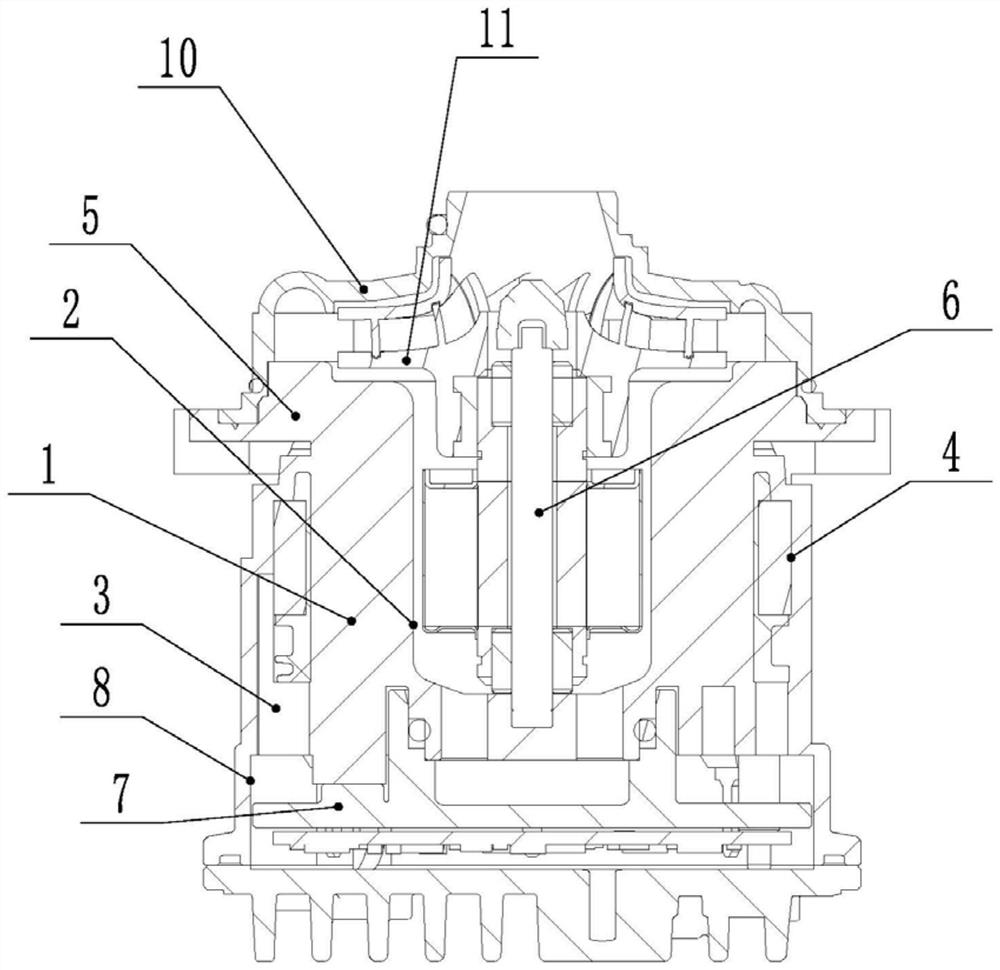

[0026] Such as Figure 1 to Figure 4 Commonly shown, a stator assembly of an electronic water pump includes a casing 1 and a stator assembly 4, wherein the casing 1 is a plastic casing, and the plastic casing 1 covers the stator assembly, wherein the plastic casing 1 The casing 1 and the stator assembly 4 are integrally formed by injection molding process, and there is a process hole 3 left by injection molding between the casing 1 and the stator assembly 4; the casing 1 is also provided with a rotor assembly installation cavity 5, said The casing 1 is integrally formed with a mandrel 6 on the bottom of the rotor assembly installation cavity 5, and the mandrel 6 is supported as the rotation center of the entire rotor; the upper end of the plastic casing 1 is also provided with a The lower flange part 5 adapted to the upper cover 10, the lower flange part 5 is located around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com