Industrial welding rod heating bin

A heating bin and welding rod technology, applied in lighting and heating equipment, drying, dryers, etc., can solve the problems of inability to meet daily welding needs, process performance deterioration, arc instability, etc., to facilitate transportation and transfer. Operation, heating effect is stable and reliable, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

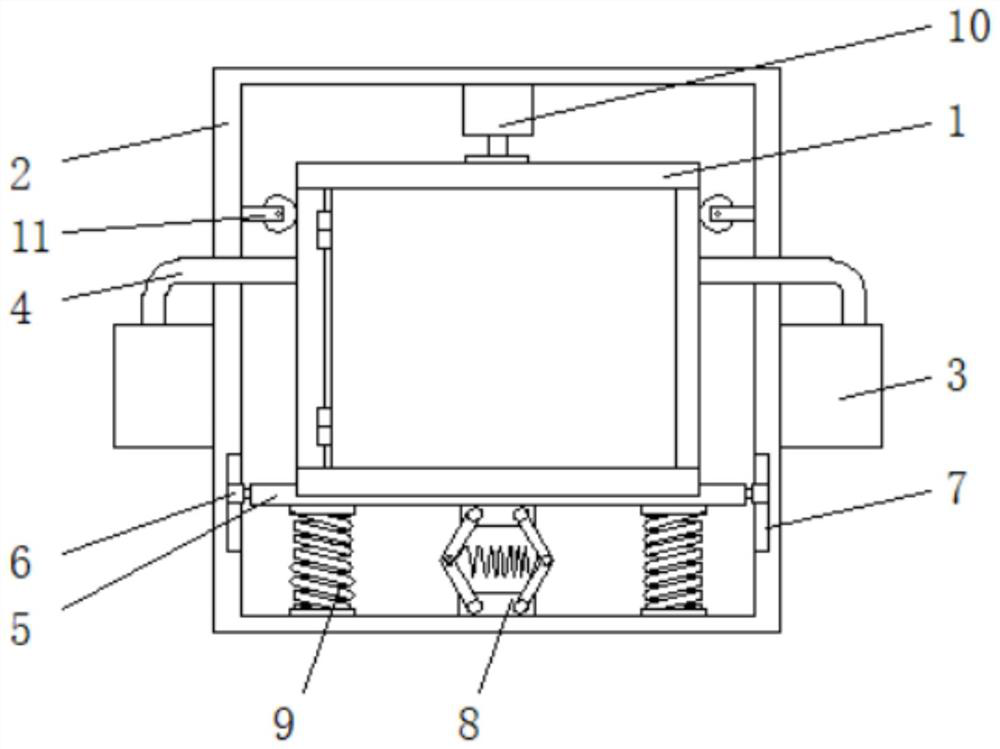

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention.

[0011] see figure 1 , this specific embodiment is realized by the following technical solutions, which comprises a heating box 1, the outer surface of the heating box 1 is covered with a layer of insulation box 2, and heaters 3 are respectively installed on both sides of the insulation box 2, The high-temperature gas generated by the heater 3 is connected to the heating box 1 through the pipeline 4. The bottom of the heating box 1 is embedded and installed on the platen 5. The four corners of the platen 5 respectively extend out the positioning sliders 6, so The inner wall of the heating box 1 is provided with a positioning chute 7 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com