Terahertz device for monitoring flame temperature field pulsation in real time and measurement method

A flame temperature, real-time monitoring technology, applied in the direction of measuring devices, thermometers, measuring heat, etc., can solve the problems of the measured temperature field disturbance, the damage of the temperature sensing element, and the hysteresis of the measurement response, so as to improve the signal-to-noise ratio and precision of the system. , Thermal noise removal, thermal noise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

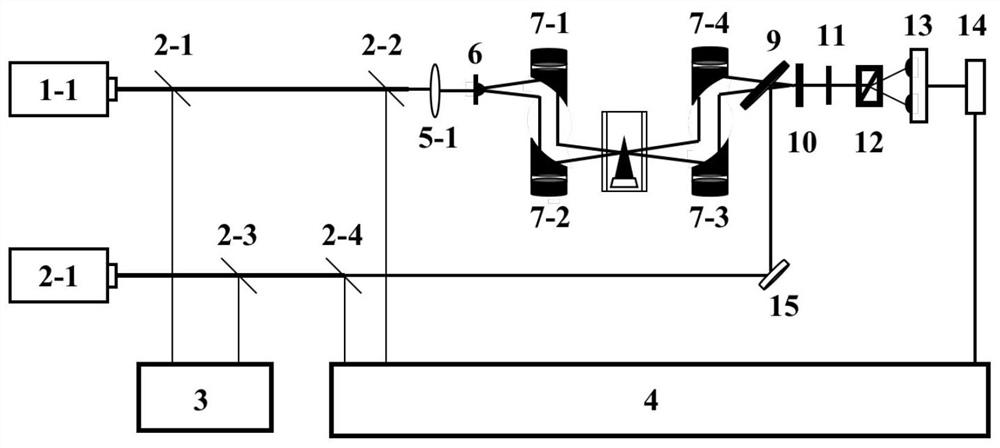

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings.

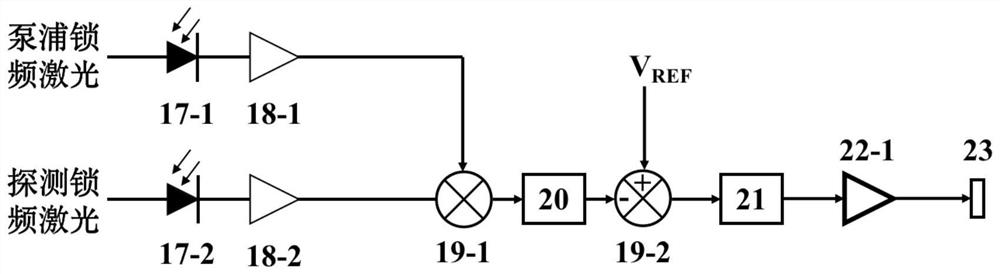

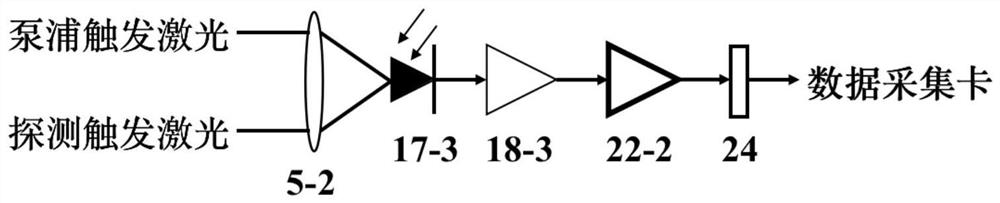

[0072] like figure 1 As shown, the terahertz device for real-time monitoring of flame temperature field pulsation includes pumping femtosecond laser 1-1, detecting femtosecond laser 1-2, beam splitter 1 2-1, beam splitter 2 2-2, beam splitter Three 2-3, beam splitter four 2-4, frequency-locking control system 3, signal trigger system 4, focusing lens one 5-1, terahertz generating crystal 6, off-axis parabolic mirror one 7-1, off-axis parabolic mirror Two 7-2, off-axis parabolic mirror three 7-3, off-axis parabolic mirror four 7-4, two-dimensional displacement platform 8, silicon wafer 9, terahertz induction crystal 10, 1 / 4 wave plate 11, Wollaston Prism 12, balance detector 13, A / D data acquisition card 14, mirror 15, computer 16.

[0073] The pumping femtosecond laser 1-1 and the detection femtosecond laser 1-2 are used to generate a pumping beam and a det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com