Method for calculating steam temperature feedforward control signal of superheater/reheater of thermal power generating unit

A thermal power unit, feedforward control technology, applied in the direction of calculation, computer-aided design, instruments, etc., can solve the problem of not considering the actual characteristics of the unit operation and changes in coal quality, and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

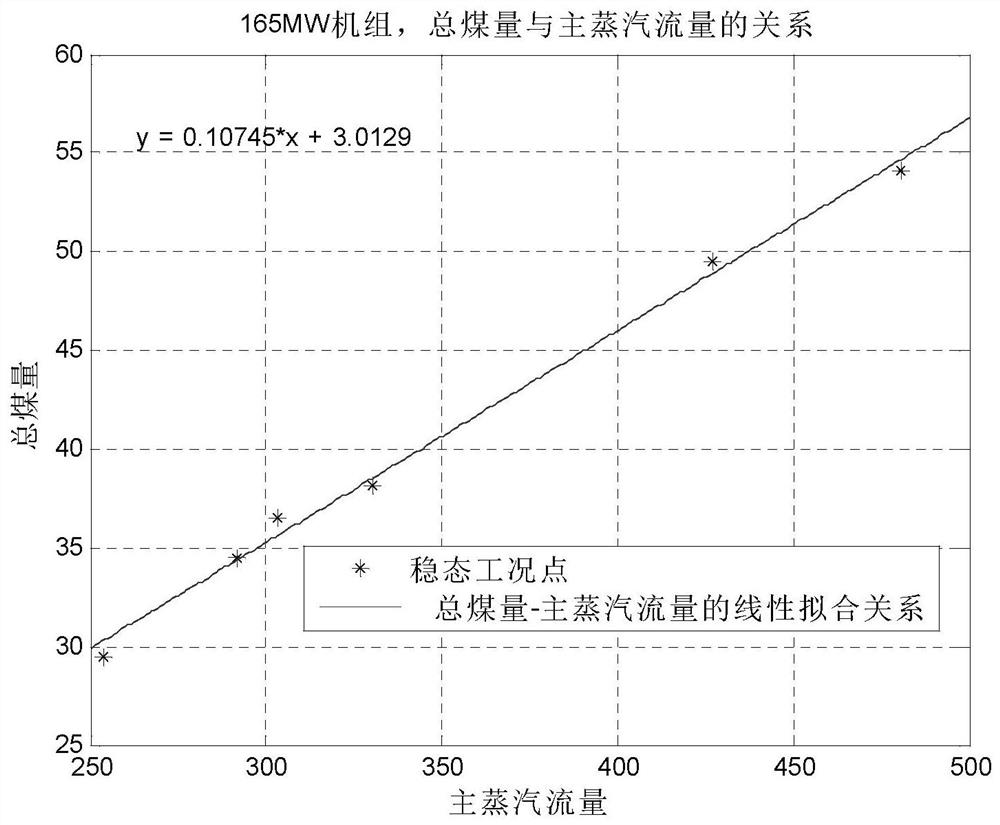

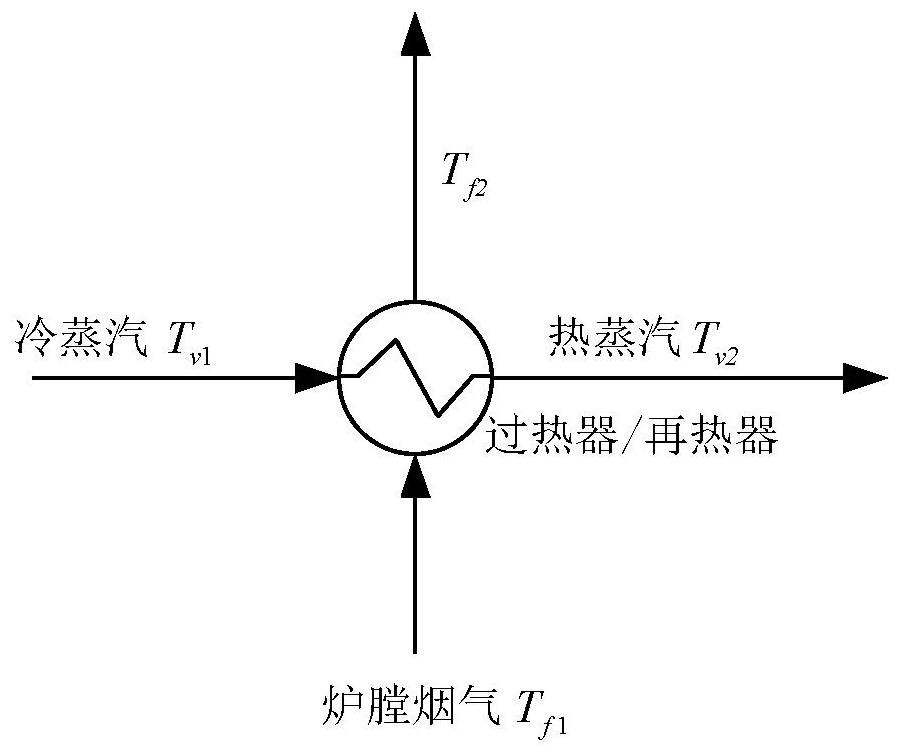

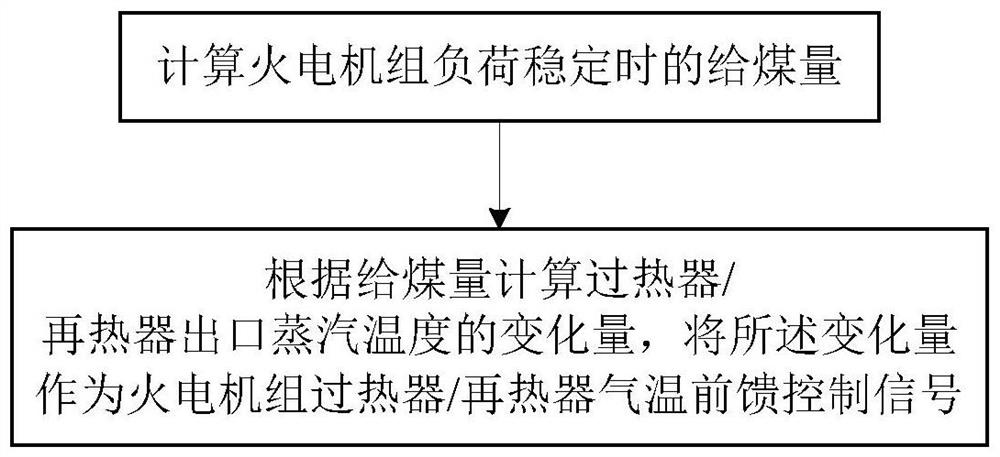

[0037] Specific implementation mode one: refer to figure 1 , 2 and 3 specifically illustrate this embodiment, a method for calculating a thermal power unit superheater / reheater steam temperature feedforward control signal described in this embodiment,

[0038] Respectively obtain the coal supply M 30% , M 40% , M 50% , M 60% , M 70% , M 80% , M 90% and M 100% , and the steam flow q v30% ,q v40% ,q v50% ,q v60% ,q v70% ,q v80% ,q v90% and q v100% , the above THA working condition (heat consumption rate acceptance working condition) refers to: the steam turbine is normally put into operation with rated steam inlet parameters, rated back pressure, and heat recovery system, the makeup water rate is 0%, and the generator can output rated power continuously. Some are also called rated output conditions.

[0039] Taking the steam flow rate as the independent variable and the coal feed rate as the dependent variable for linear fitting, the linear fitting equation is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com