Current-based longitudinal differential protection method and system for belt conveyor

A technology of longitudinal differential protection and belt conveyor, applied in the direction of protection reacting to overcurrent, emergency protection device for automatic disconnection, emergency protection circuit device, etc. Problems such as expansion, refusal and misoperation, to achieve the effect of improving accuracy and reliability, high accuracy and reliability, and avoiding the expansion of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

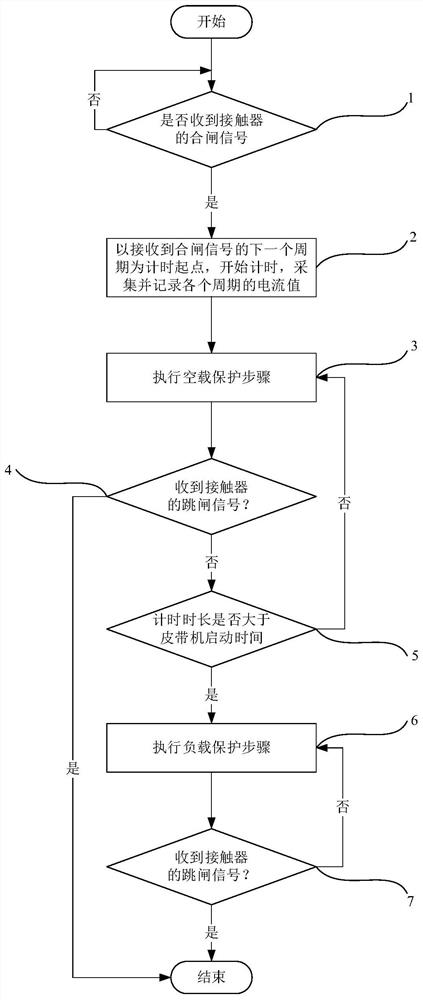

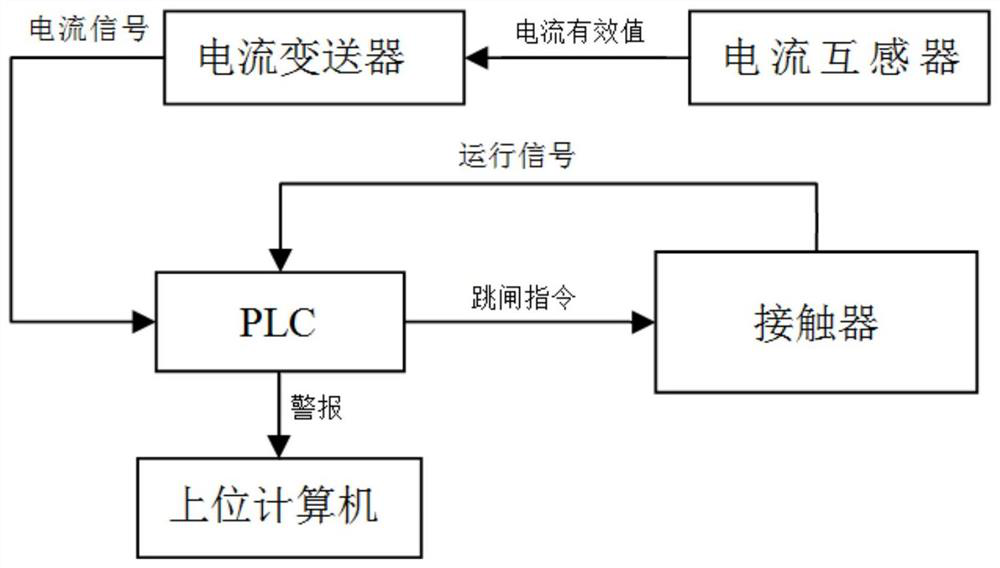

[0063] A current-based longitudinal differential protection method for belt conveyors, which is used to protect the belt conveyors during operation, such as figure 2 The protection method is based on the belt conveyor motor protection device. The belt conveyor motor protection device includes current transformers, current transmitters, PLCs, upper computers and contactors on the belt conveyor motors. The current transformers are connected in series to each belt conveyor in the coal conveying system. In the power circuit of the motor, the current transformer collects the effective value of the current of the belt conveyor and sends it to the current transmitter. The auxiliary contact signal is sent to the PLC switch input terminal as the data for the PLC to judge the running state of the belt conveyor motor. The PLC sends an alarm to the upper computer, and the staff checks the alarm through the upper computer. The isolation relay is connected to the contactor trip circuit.

...

Embodiment 2

[0100] A current-based longitudinal differential protection system for belt conveyors, including a no-load judging module, a current acquisition module, a no-load protection module and a load protection module;

[0101] The current acquisition module periodically collects and stores the current value of the belt conveyor;

[0102] The no-load judging module judges whether the belt conveyor is running without load, if so, the no-load protection module protects the belt conveyor through the no-load protection step, otherwise the load protection module protects the belt conveyor through the load protection step;

[0103] The no-load protection module includes a data packing unit, a difference calculation unit, a first protection unit and a data update unit, and the no-load protection steps include:

[0104] The data packing unit packs the set number of current values collected continuously into a set of current time series data;

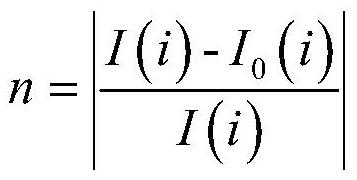

[0105] The difference calculation unit calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com