Rapid cultivation method of moss crust

A cultivation method, moss crust technology, applied in the field of environmental engineering, can solve the problems of long time consumption, damage of crust tissue, death of crust stem and leaf fragments, etc., and achieve the effect of shortening the development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

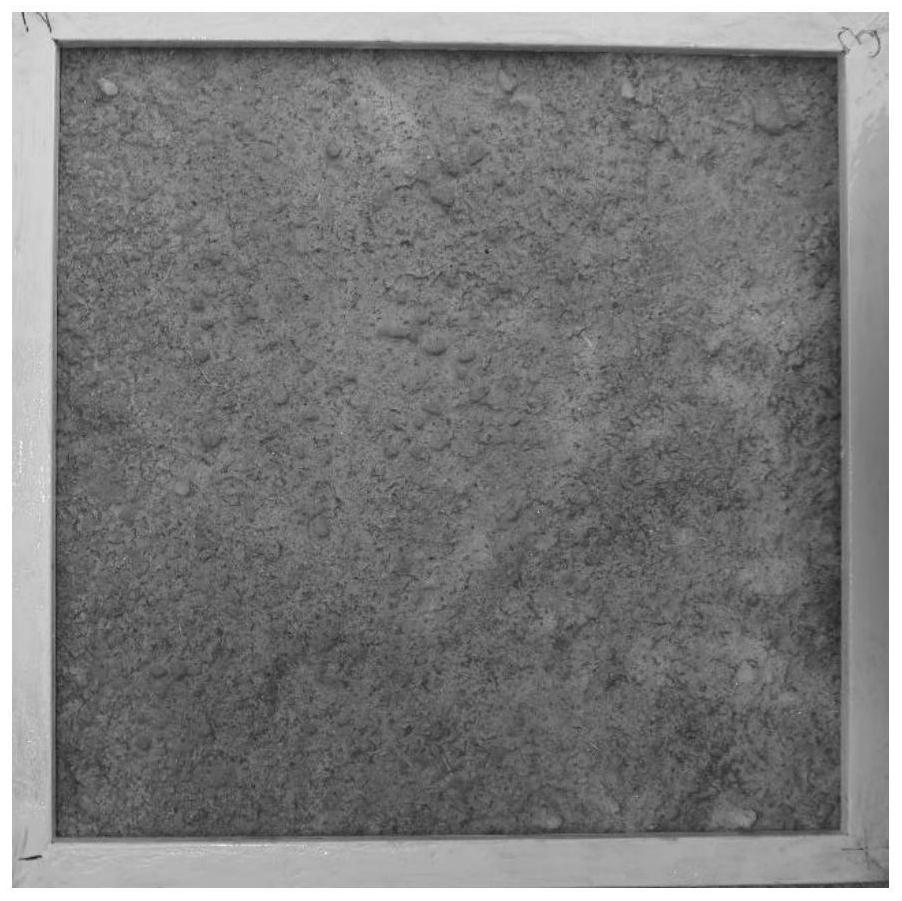

Image

Examples

Embodiment 1

[0033] Field collection thickness is 2.65mm, plant density is 20 plants / cm 2 1. For sand moss crust samples in good growth condition, place them in a cool place away from light to 14%, so that the crust and soil can be separated easily. Gently rub the sand moss crust samples with your hands to make the sand moss crust samples and soil preliminary Separation, pass the sand moss crust sample through a 120-mesh soil sampling sieve, and spread the sieved crust stem and leaf fragments in time for planting, the inoculum amount is 500g / m 2 , cover the sunshade net, the temperature is controlled at 20°C, the light is outdoor natural light, watered regularly, the soil moisture content is controlled at 28%, and the sand moss crust is obtained after cultivating for 7 days.

Embodiment 2

[0035] Field collection thickness is 2mm, plant density is 25 plants / cm 2 1. For sand moss crust samples in good growth condition, place them in a cool place away from light to 12%, so that the crust and soil are easier to separate. Gently rub the sand moss crust samples with your hands to make the sand moss crust samples and soil preliminary Separation, pass the sand moss crust sample through a 130-mesh soil sampling sieve, and spread the sieved crust stem and leaf fragments in time for planting, the inoculum amount is 450g / m 2 , cover the sunshade net, the temperature is controlled at 22°C, the light is outdoor natural light, watered regularly, the soil moisture content is controlled at 25%, and the sand moss crust is obtained after cultivation for 8 days.

Embodiment 3

[0037] Field collection thickness is 3mm, plant density is 15 plants / cm 2 1. The sand moss crust sample in good growth condition should be placed in a cool place away from light to 15%, so that the crust and soil can be separated easily. Gently rub the sand moss crust sample with hands to make the sand moss crust sample and the soil preliminary Separation, pass the sand moss crust sample through a 110-mesh soil sampling sieve, and spread the sieved crust stem and leaf fragments in time for planting, the inoculum amount is 530g / m 2 , cover with a sunshade net, the temperature is controlled at 18°C, the light is outdoor natural light, watered regularly, the soil moisture content is controlled at 30%, and the sand moss crust is obtained after cultivating for 10 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com