Saliva collector with exhaust function and injection molding process thereof

A collector and saliva technology, applied in the field of saliva collectors, can solve problems such as easy blocking of the funnel outlet, lower work efficiency, poor exhaust, etc., to prevent liquid loss or pollution, improve operation convenience, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

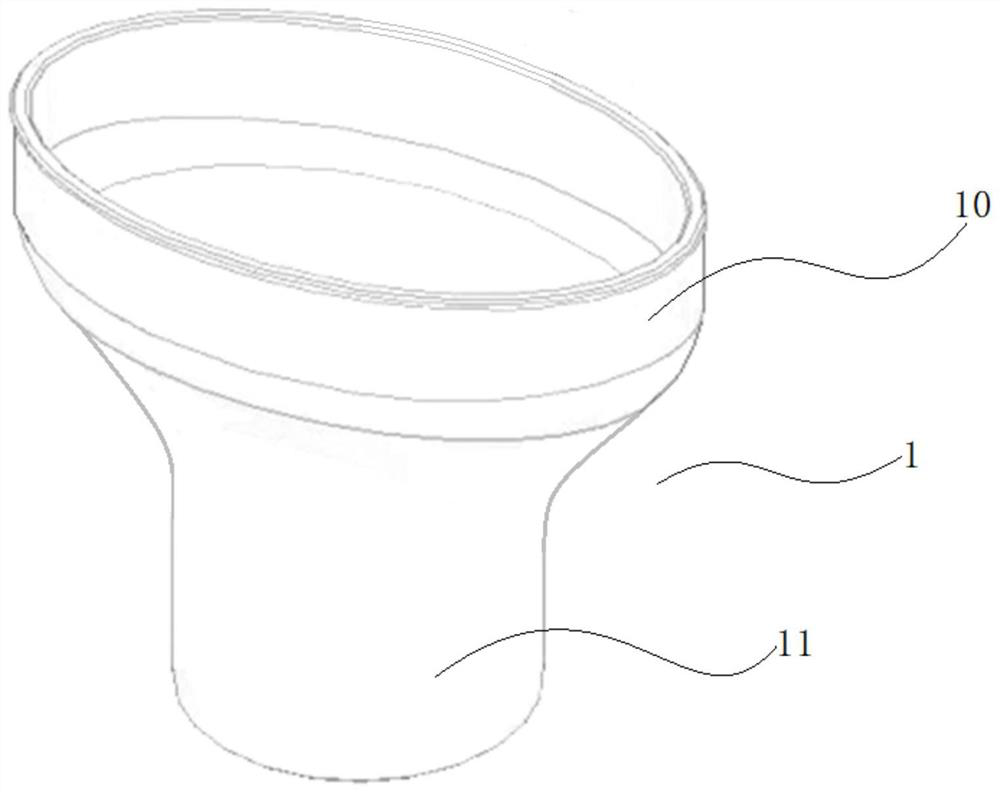

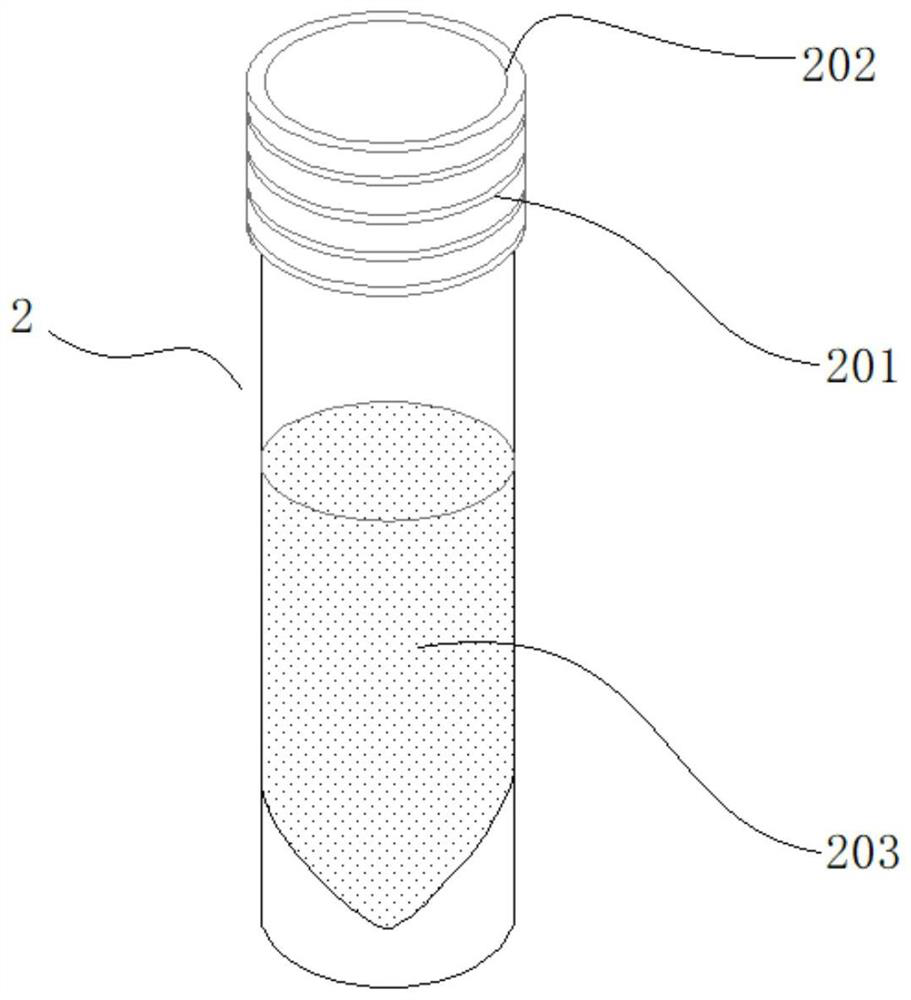

[0020] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the saliva collector with exhaust function is composed of a collection funnel 1 and a collection tube 2, and a preservation solution 203 needs to be poured into the collection tube 2.

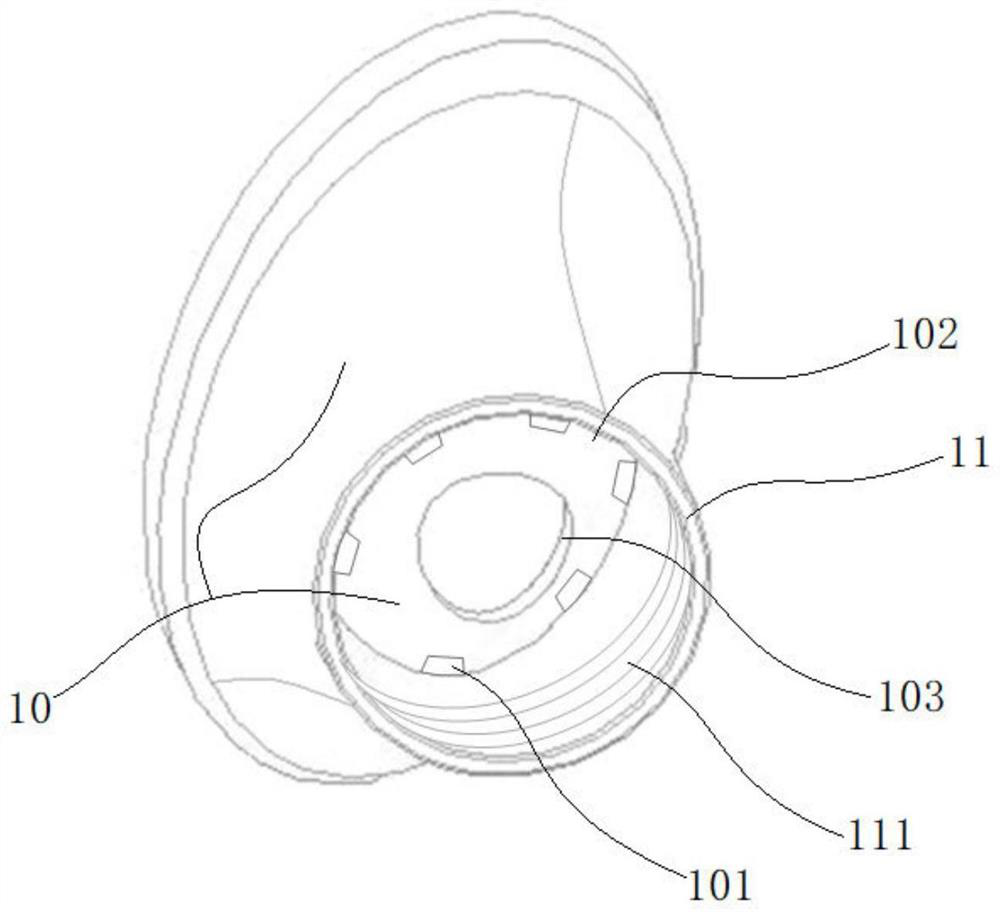

[0021] The collection funnel 1 is composed of a funnel 10 and a connecting sleeve 11, the connecting sleeve 11 is provided with an internal thread 111, and the collecting pipe 2 is provided with an external thread 201 corresponding to the internal thread 111, and the internal thread 111 and the external thread 201 are non-sealed pipe thread. The upper port 112 of the connecting sleeve 11 is fixed circumferentially around the outer wall of the lower part of the funnel 10. Around the outer wall of the lower part of the funnel 10, six ring-shaped and evenly distributed limiting blocks 101 are arranged. Between two adjacent limiting blocks 101 there are The gap 102 formed by the spacer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com