Multi-winding composite traction elevator and adjusting method

An adjustment method and multi-winding technology, applied in the field of elevators, can solve the problems of small elevator load, small traction ratio, and adding elevators, and achieve the effects of high traction ratio, reduced failure rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

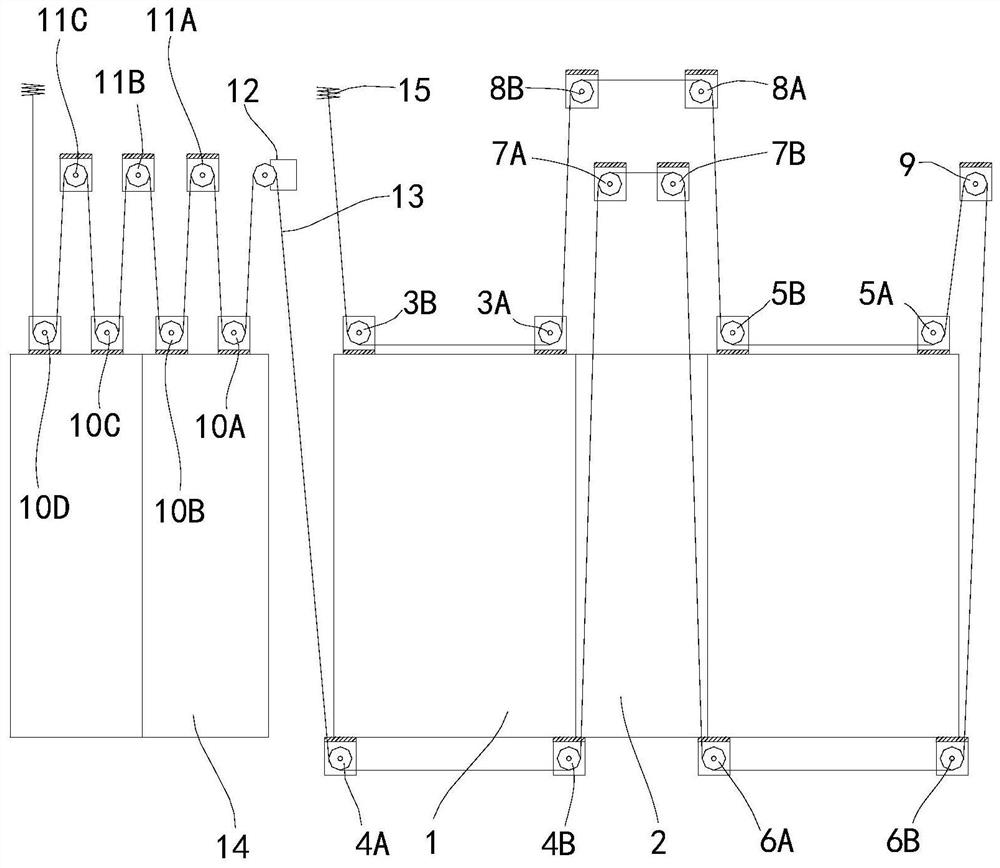

[0018] Example 1. A multi-winding composite pair of lifts, the elevator is a ladder, including a control system and a wellway, a car 1 and a heavy device in the wellway, and the car 1 connects to the heavy device through the traction system. The characteristics are as follows:

[0019] The central portion of the car 1 is provided with a passage 2, and two of the top of the car 1 are provided on the first movable pulley set 3a, 3b on the passage 2 side, and two at the bottom of the car 1 are provided in channel 2. On the top of the second moving pulleys 4a, 4b, the top of the car 1 is provided with a third moving pulley set 5a, 5b located on the other side of the channel 2, and two on the bottom of the car 1 are provided on the other side of the channel 2. The fourth movable pulleys 6a, 6b, and the channel 2 are provided with two first-stop pulley sets 7a, 7b close to the top of the wellway, and there are two second fixed pulley sets 8a, 8b, the car. One side is provided with a thi...

Embodiment 2

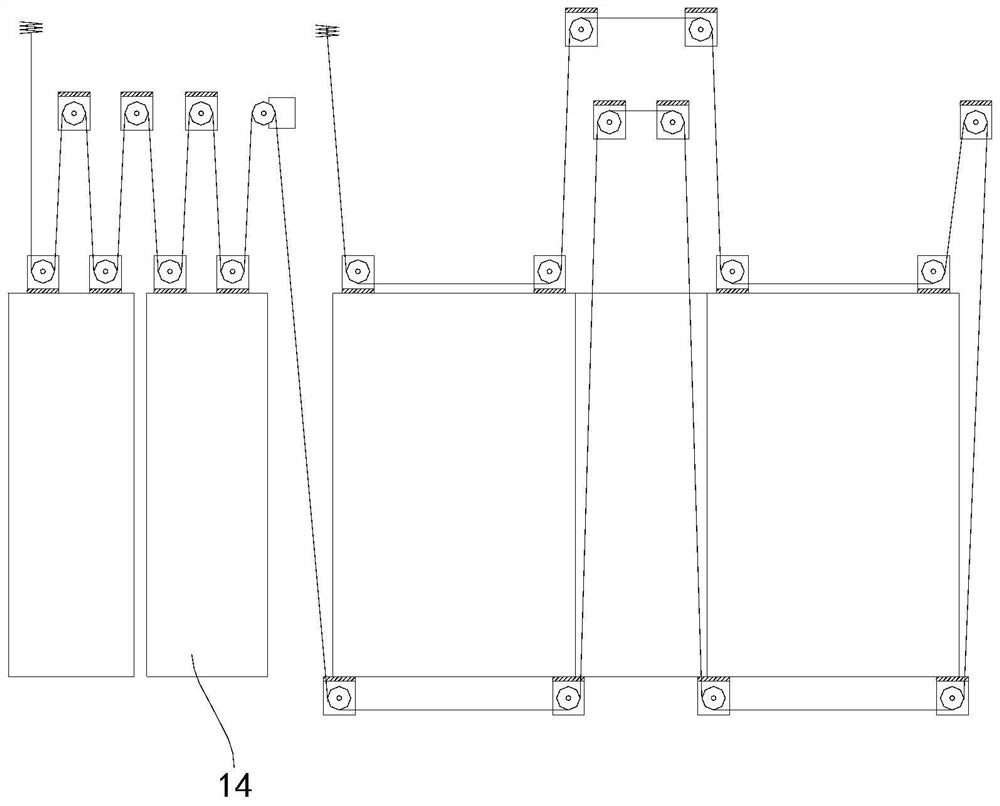

[0024] Example 2. Unlike Example 1, the counterweight device is a split structure, composed of two separate splittings, and the two split weights 14 are located on both sides of the car 1.

Embodiment 3

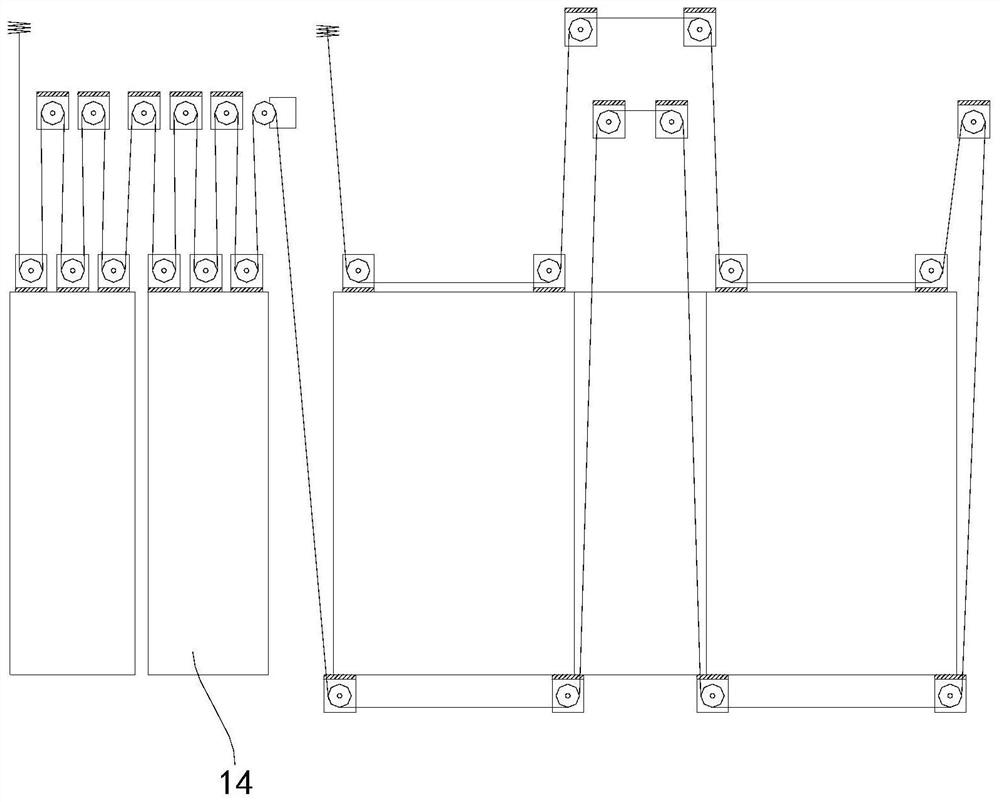

[0025] Example 3. Unlike Example 1, the counterweight device is a split structure, composed of two independent split values, and the number of the fifth moving pulley is six, eight, ten or twelve. A, the number of fourth sleeve is less than the number of fifth moving pulleys. Each split is equal to the number of fifth moving pulley packages on the weight 14. By changing the number of strokes of the fifth moving pulley, the more the number of the fifth moving pulley set 10 is, the larger the overall weight of the heavy device, the smaller the stroke of the heavy device.

[0026] In the elevators of Example 1 and Example 2, the traction of the heavy device was the same as the traction ratio of the car, which made the counter-repellent device and the car as the car. The weight of the room is close to the weight of the heavy device, and further reduces the cost of the elevator. In the elevator of Example 3, the traction ratio of the heavy device is larger than the traction ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com