Wind speed early warning control method for large hoisting operation equipment based on wind speed signals

A technology for large-scale hoisting and operating equipment, applied in speed/acceleration/shock measurement, measuring devices, transportation and packaging, etc., can solve the lack of wind factors and other problems, improve operating efficiency, realize intelligent judgment, and have practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

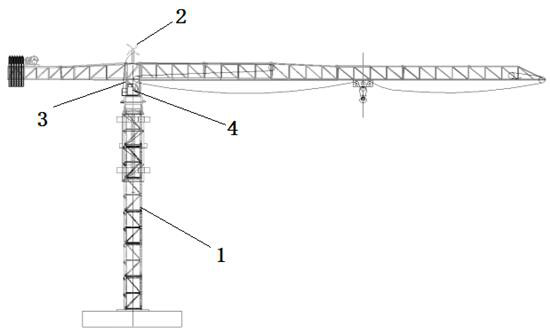

[0030] by attaching figure 1 It can be seen that the present invention relates to a wind speed early warning control method for large-scale hoisting equipment based on wind speed signals, using a ZSC70240 / 80t horizontal self-elevating tower crane, and installing a WFS on the upper beam of the cab of the horizontal self-elevating tower crane 1 -1-1 wind speed measuring instrument 2, and the wind speed signal detected by the wind speed measuring instrument 2 is transmitted to the wind speed monitoring information processing system 4 in the cab through the wire 3, and the wind speed monitoring information processing system 4 performs the wind speed information in the field operation area Real-time monitoring, wind speed monitoring information processing system 4 sets the wind speed warning value and limit value according to the requirements of crane safety operation regulations, and sends warning or stop operation information to the operator at the wind speed warning value and lim...

Embodiment 2

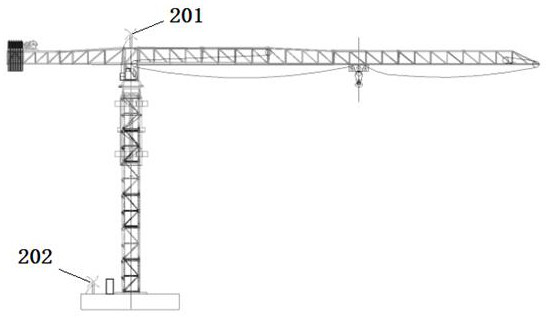

[0038] The wind speed monitoring principle of embodiment two is the same as embodiment one, only differs in the way, as attached figure 2 Shown; It involves a wind speed early warning control method for large-scale hoisting equipment based on wind speed signals, using an ultra-high level self-elevating tower crane (the hoisting height is above 110 meters), in the cab of the ultra-high level self-elevating tower crane A WFS-1-1 wind speed measuring instrument 201 is installed on the upper beam, and a WFS-1-1 wind speed measuring instrument 202 is also installed on the base of the ultra-high level self-elevating tower crane. The measuring instrument monitors the wind conditions on the top and bottom of the ultra-high level jack-up tower crane respectively, and at the same time transmits the wind speed signal detected by the anemometer to the wind speed monitoring information processing system in the cab through the wire, and the wind speed monitoring information is processed Th...

Embodiment 3

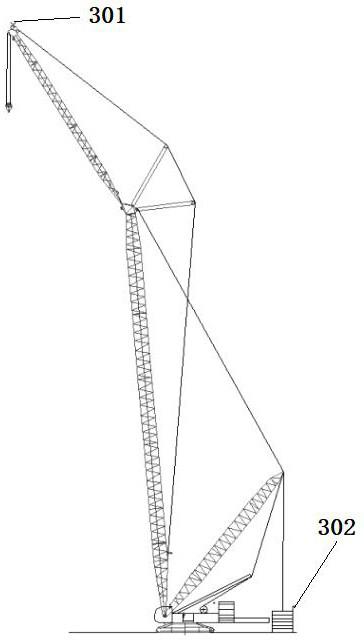

[0048] The operating principle method of embodiment three is the same as embodiment one, but according to different operating equipment, the installation position of the anemometer is different, as attached image 3 As shown, it is a wind speed early warning control method for large-scale hoisting equipment based on wind speed signals. Anemometers are installed on the top and bottom of the Manitowoc 750t crawler crane (Manitowoc 18000), and the anemometers detect The wind speed signal is transmitted to the wind speed monitoring information processing system through the wire, and the wind speed information in the field operation area is monitored in real time. The limit value sends an early warning or stop operation information to the operator, and stops the operation in a dangerous environment in time.

[0049] The installation of the anemometer on the top and bottom of the Manitowoc 750t crawler crane (Manitowoc 18000) is to install the anemometer 301 on the top of the Manito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com