Method for recovering galantamine intermediate raw material 2-bromo-5-hydroxy-4-methoxybenzoic acid

A technology of methoxybenzoic acid and galantamine, applied in the field of biomedicine, can solve the problems of high cost of production materials and high cost of three-waste treatment, and achieve the effect of reducing waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

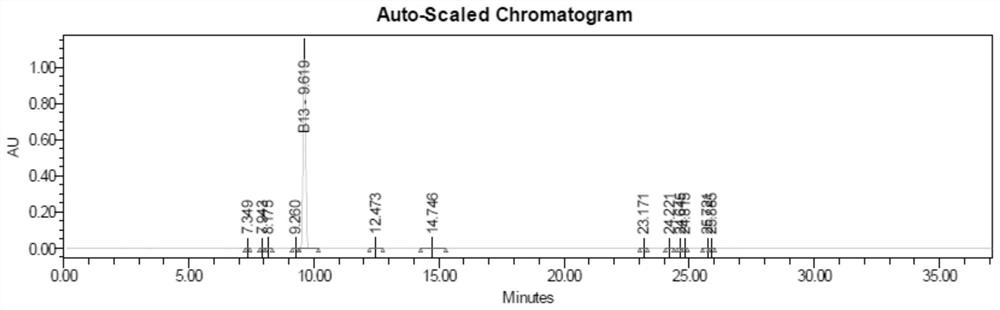

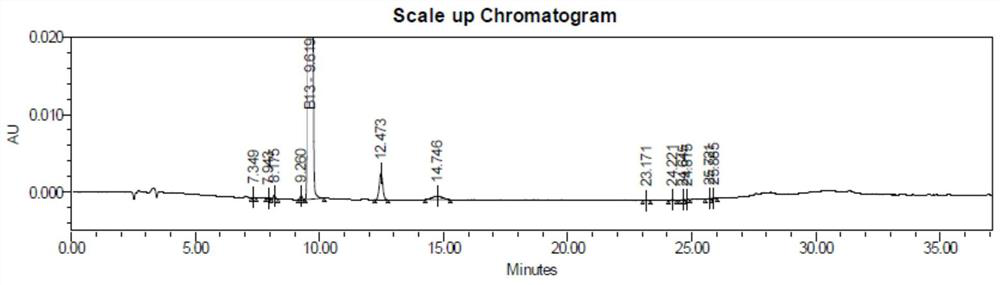

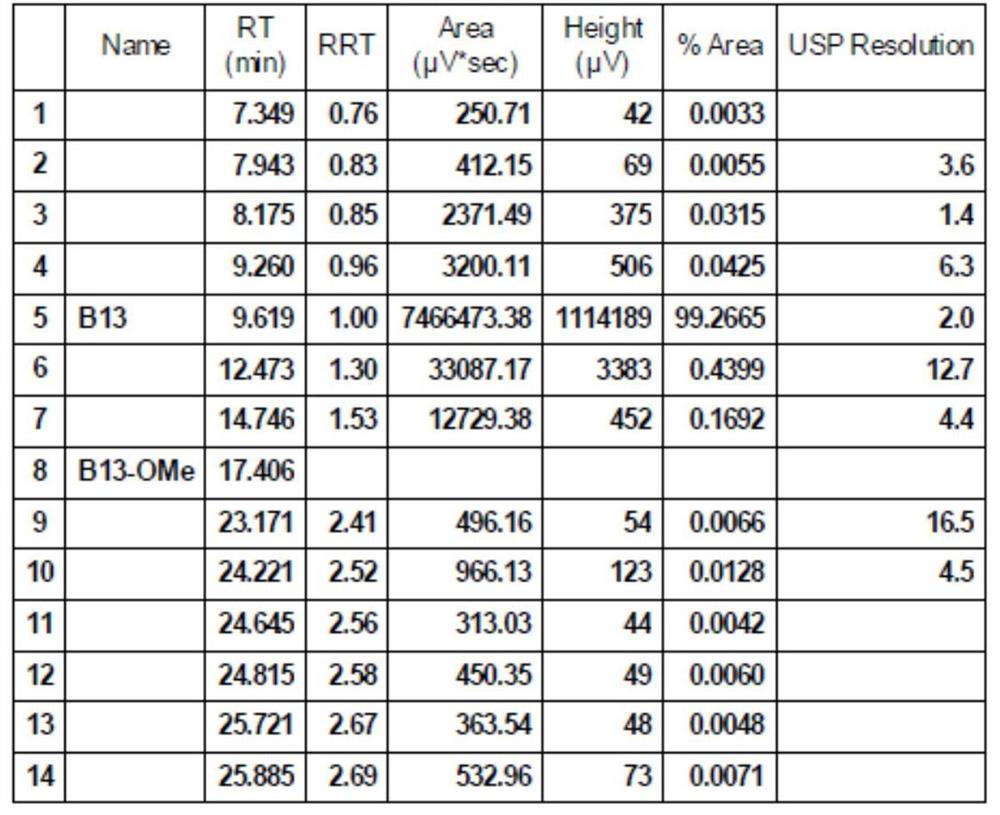

Image

Examples

Embodiment 1

[0074] Step 1: Add soft water and sodium hydroxide to the RX-2102 reaction kettle, stir until the sodium hydroxide solution is completely dissolved, and transfer the sodium hydroxide solution to the bucket for use; the concentration of the sodium hydroxide solution is 20%.

[0075] Step 2: Under nitrogen, add soft water and 36% hydrochloric acid into the RX-2105 reactor, stir for ≥ 10 minutes to obtain a hydrochloric acid solution, and transfer the hydrochloric acid solution to a barrel for use; the concentration of the hydrochloric acid solution is 15%.

[0076] Step 3: Under nitrogen condition, add the B13-OMe to be recovered into the RX-2102 reactor, and take a sample to detect that the B13-OMe content is 11%.

[0077] Step 4: Distill the contents of the RX-2102 reactor to 1 times, and the inner temperature of the RX-2102 reactor is 21°C.

[0078] Step 5: Under nitrogen, add the sodium hydroxide solution into the RX-2102 reaction kettle, and control the internal temperatur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap