Method for judging disappearance of soft melting zone in blowing-out process

A technology of reflow zone and furnace top, which is applied in the field of iron and steel metallurgy, can solve the problems of slow and limited furnace shutdown process, and the traditional method cannot timely reflect whether the reflow zone disappears, etc. The effect of furnace safety, reliability and precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention are further described below through examples, but the specific embodiments of the present invention are not limited to the following examples.

[0025] First of all, the traditional calculation method is used, that is, to judge whether the reflow zone disappears according to the inflection point of the CO2 content in the gas analysis.

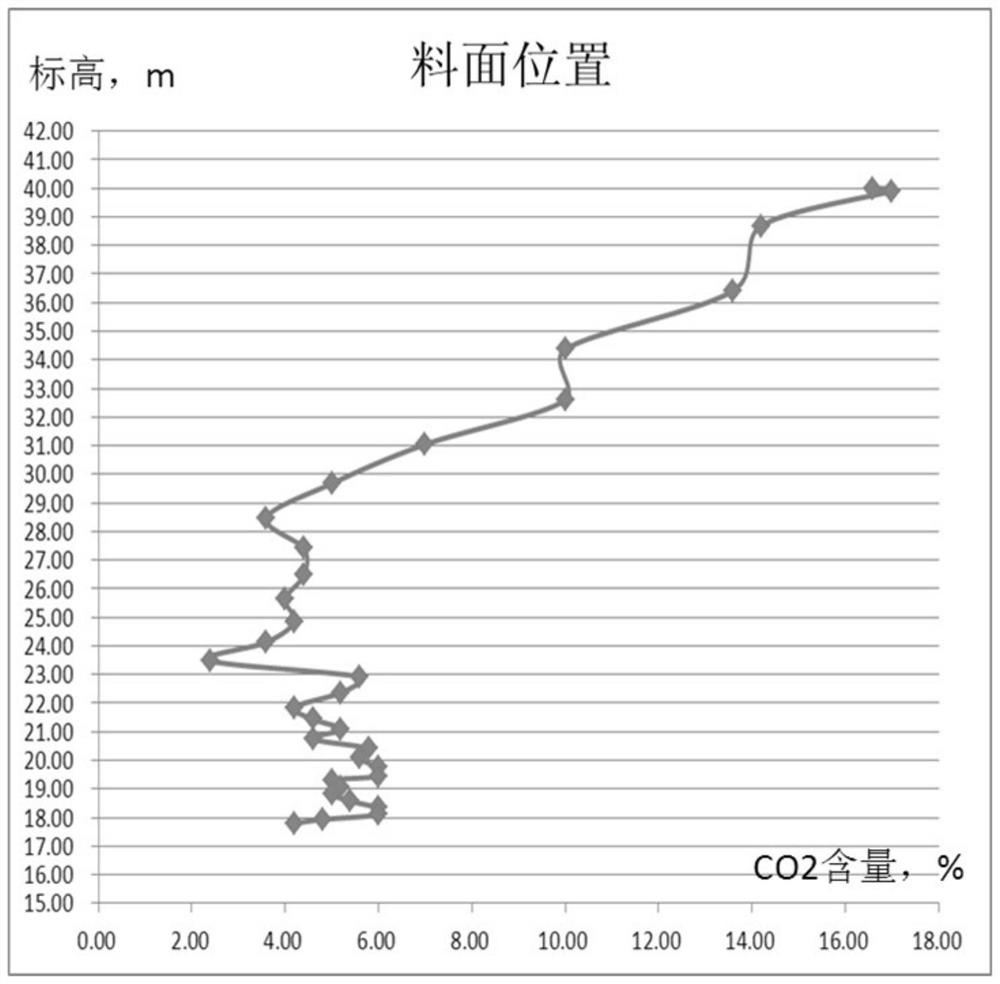

[0026] Taking the CO2 curve of the top of a blast furnace during shutdown as an example, the zero position of the blast furnace feed line is 42 meters above sea level, and the elevation of the tuyere center line is 14.97 meters. The relationship between the top gas CO2 curve and the feed surface elevation during the shutdown process is as follows figure 1 Shown:

[0027] From figure 1 It can be seen from the figure that when the material level is about 28 meters above sea level, the CO2 of the furnace top gas begins to show an inflection point. According to past experience, the parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com