Brazing and aging integrated treatment process for GH4099 nickel-based high-temperature alloy

A nickel-based superalloy, GH4099 technology, applied in the field of brazing and aging integrated treatment process, can solve the problems of slow cooling, affecting the effect of aging strengthening, low strength of nickel-based superalloy, etc., to improve the strength, enhance the aging strengthening effect, The effect of fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The composition of the GH4099 nickel-based superalloy used in this example is as follows: C 0.03wt%, Cr 18.6wt%, Fe 0.8wt%, Co 6.3wt%, W 5.8wt%, Mo 4.0wt%, Al 2.1wt% , Ti 1.2wt%, the balance being Ni.

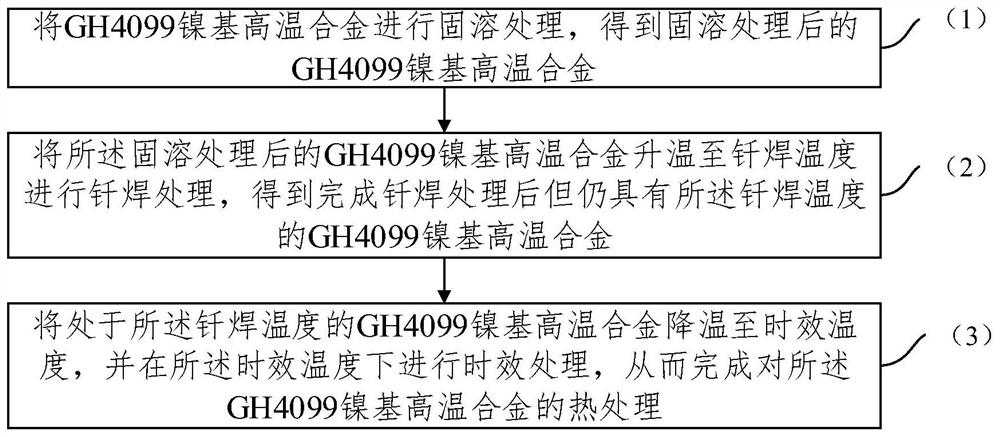

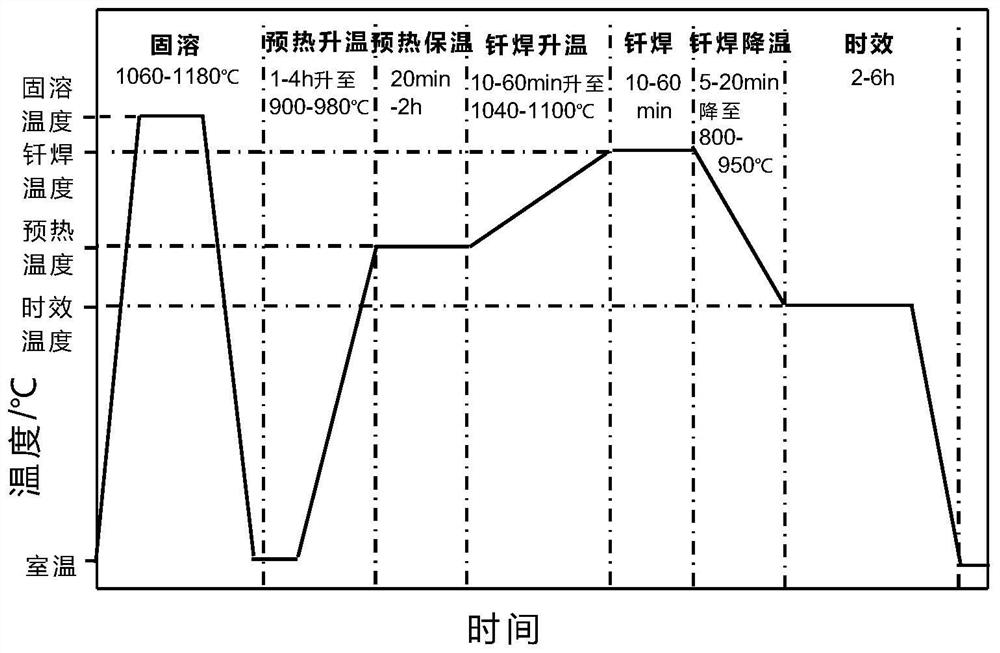

[0051] as per figure 2 The process curve shown is an integrated treatment of brazing and aging for the GH4099 nickel-based superalloy, including the following steps:

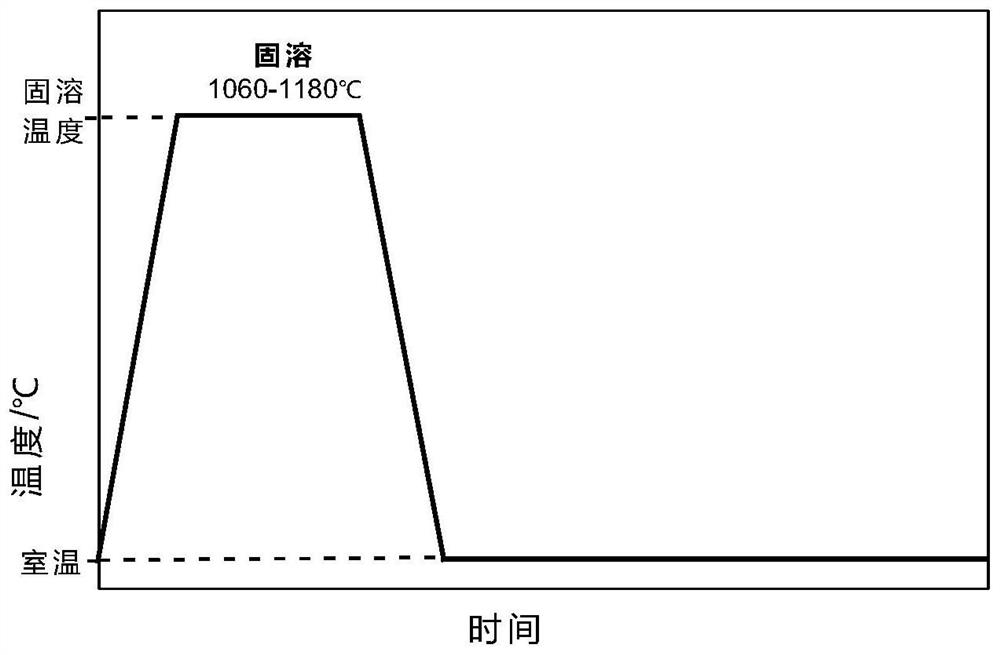

[0052] (1) heating the GH4099 nickel-based superalloy to a solution temperature of 1080° C., performing solution treatment for 20 minutes, and cooling to room temperature by air to obtain the solution-treated GH4099 nickel-based superalloy;

[0053] (2) Place the GH4099 nickel-based superalloy after the solution treatment in a vacuum brazing furnace, heat up to a preheating temperature of 940° C. in 1.5 hours, and preheat and keep it warm for 40 minutes;

[0054] The preheating temperature is raised to the brazing temperature of 1070° C. within 10 minutes, and the preheated GH4099 nickel-based superallo...

Embodiment 2

[0059] The composition of GH4099 nickel-based superalloy is as follows: C 0.03wt%, Cr 18.6wt%, Fe 0.8wt%, Co6.3wt%, W 5.8wt%, Mo 4.0wt%, Al 2.1wt%, Ti 1.2wt%, The balance is Ni.

[0060] as per figure 2 The process curve shown is an integrated treatment of brazing and aging for the GH4099 nickel-based superalloy, including the following steps:

[0061] (1) heating the GH4099 nickel-based superalloy to a solution temperature of 1100° C., performing solution treatment for 30 minutes, and cooling to room temperature by air to obtain the solution-treated GH4099 nickel-based superalloy;

[0062] (2) Place the GH4099 nickel-based superalloy after the solution treatment in a vacuum brazing furnace, heat up to a preheating temperature of 940° C. in 2.5 hours, and preheat and keep it warm for 60 minutes;

[0063] The preheating temperature is raised to the brazing temperature of 1060° C. within 30 minutes, and the preheated GH4099 nickel-based superalloy is brazed with BNi73CrFeSiB ...

Embodiment 3

[0067] The composition of GH4099 nickel-based superalloy is as follows: C 0.03wt%, Cr 18.6wt%, Fe 0.8wt%, Co6.3wt%, W 5.8wt%, Mo 4.0wt%, Al 2.1wt%, Ti 1.2wt%, The balance is Ni.

[0068] as per figure 2 The process curve shown is an integrated treatment of brazing and aging for the GH4099 nickel-based superalloy, including the following steps:

[0069] (1) heating the GH4099 nickel-based superalloy to a solution temperature of 1080° C., performing solution treatment for 20 minutes, and cooling to room temperature by air to obtain the solution-treated GH4099 nickel-based superalloy;

[0070] (2) Place the GH4099 nickel-based superalloy after the solution treatment in a vacuum brazing furnace, heat up to a preheating temperature of 950° C. in 3.5 hours, and preheat and keep it warm for 100 minutes;

[0071] The preheating temperature is raised to the brazing temperature of 1080° C. within 30 minutes, and the preheated GH4099 nickel-based superalloy is brazed for 10 minutes us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com