Equipment for efficiently converting straw waste

A waste and high-efficiency technology, applied in the field of equipment for efficient conversion of straw waste, can solve the problems of inconvenient use of the device, and achieve the effects of compact structure, convenient subsequent processing, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

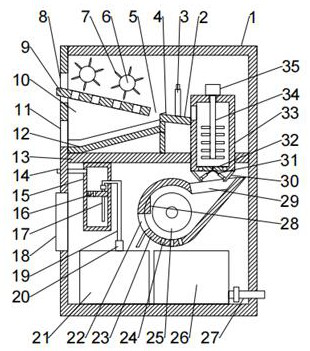

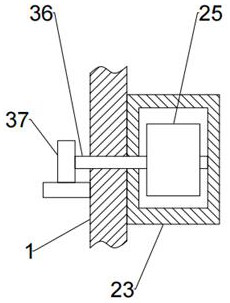

[0024]Embodiment: When in use, first put the straw material from the feed port 8 into the feed plate 9, and start the electric roller 6 at the same time, and the electric roller 6 will flatten the straw material, and at the same time, the electric roller 6 will The comb teeth 7 will comb out the impurities, and the impurities will enter the cavity 10 below from the opening on the feed plate 9 and the space 5 at one end to be discharged, and then start the cutter 3 and the first drive motor 35 at the same time to remove the straw. The material is cut and crushed, and then the hydraulic cylinder 31 is started to open the bottom plate 32, and the crushed straw material is filled into the cylindrical box 23, and the second drive motor 37 is started at the same time, so that the rolling roller 25 rotates, and the material is rolled , the liquid will flow into the liquid storage tank 26, and the solid will enter the incinerator 21 through the slag outlet 22 to realize solid-liquid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com