Device and method for measuring stress relaxation of fiber reinforced composite rib

A technology for measuring fibers and reinforcing composites, applied to measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., to achieve high measurement accuracy, simple structure, and avoid stress loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

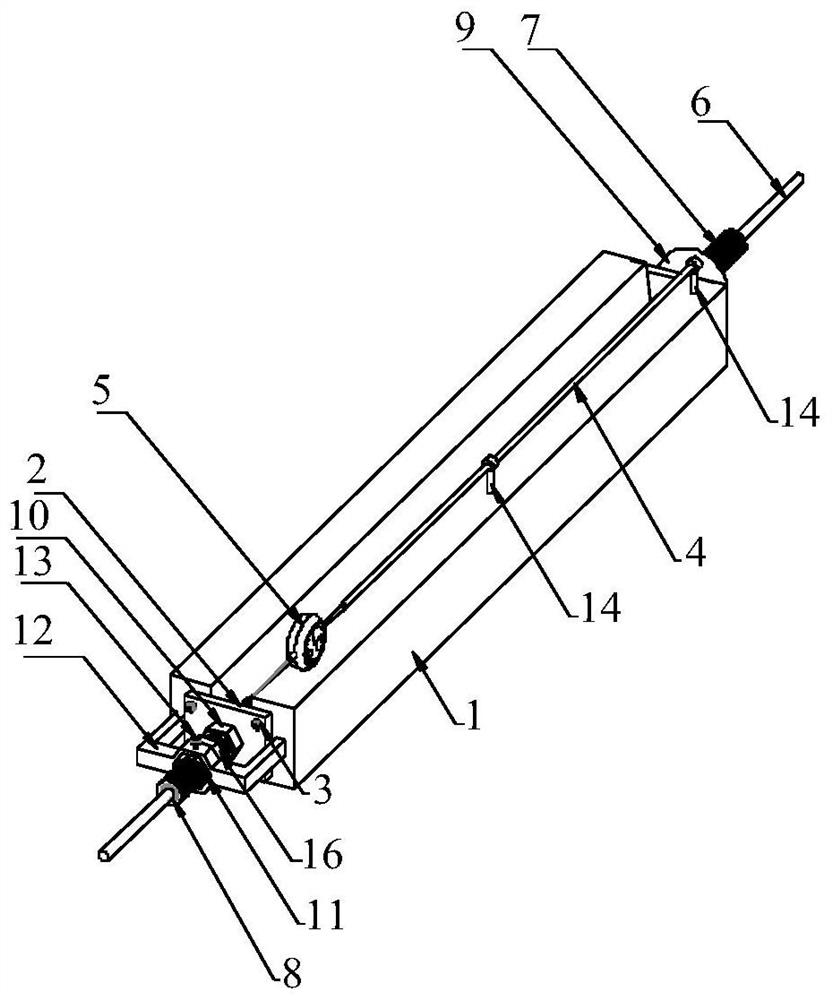

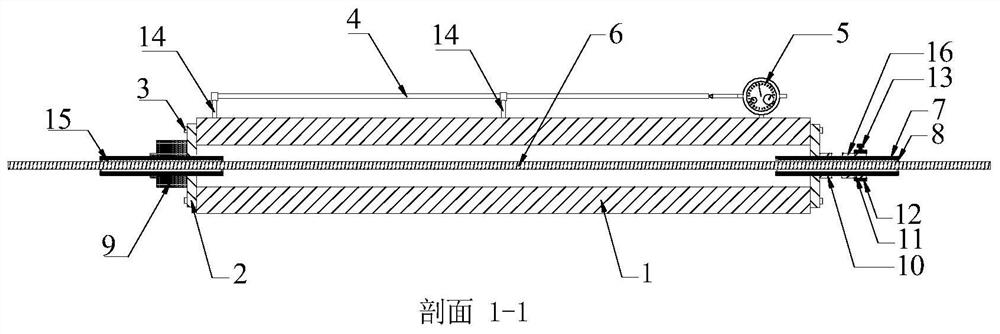

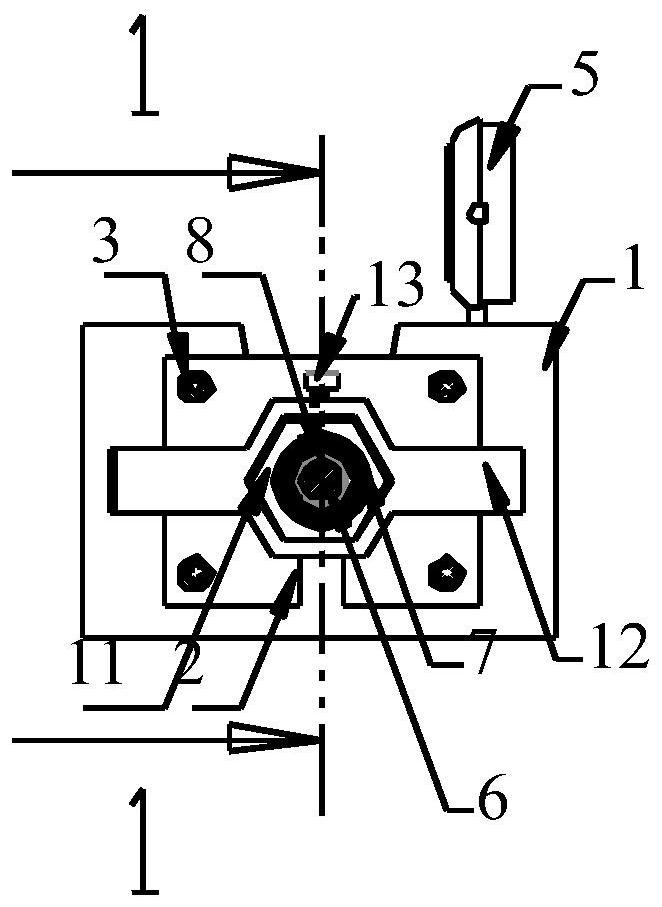

[0049] Devices for measuring the stress relaxation of fiber reinforced composite tendons, such as figure 1 As shown, it includes longitudinal support 1, centering backing plate 2, fixing screw 3, strain conducting iron rod 4, dial indicator 5, FRP tendon 6, threaded sleeve 7, centering rubber plug 8, through-center load sensor 9, Loading nut 10, limit-turn nut 11, caliper 12, limit-turn screw 13, threaded pin 14 with round hole, epoxy resin 15 and auxiliary nut 16, all have national standard fine thread inside and outside threaded sleeve 7. The thickness of the epoxy resin used in this measuring device should be 1-3mm.

[0050] Such as figure 2 and image 3 As shown, the two ends of the longitudinal support 1 are respectively fixedly connected by the fixing screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com