Belt conveyor surface state detection method and device based on convolutional neural network

A convolutional neural network and surface state technology, which is applied in neural learning methods, biological neural network models, neural architectures, etc., can solve the problems of inability to detect real-time belt surface state, inability to predict belt breakage, etc., to avoid serious economic losses, Improve accuracy and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

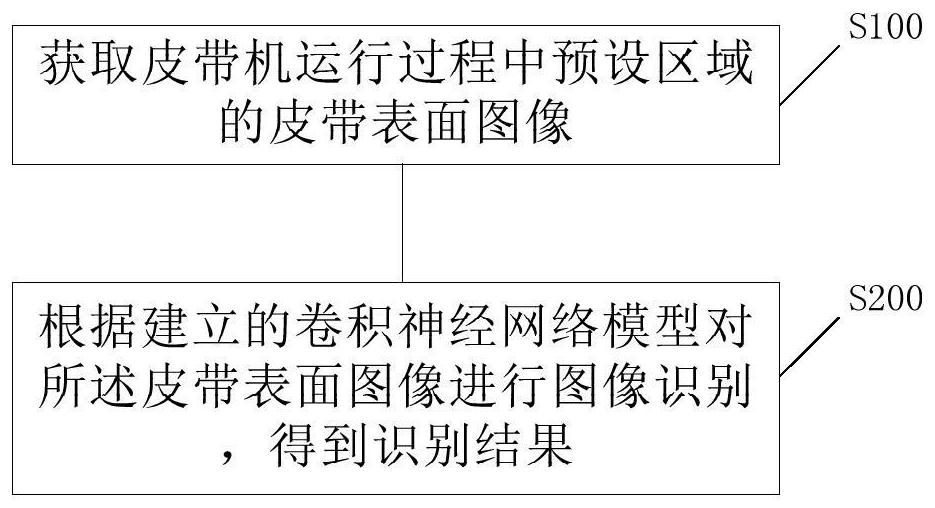

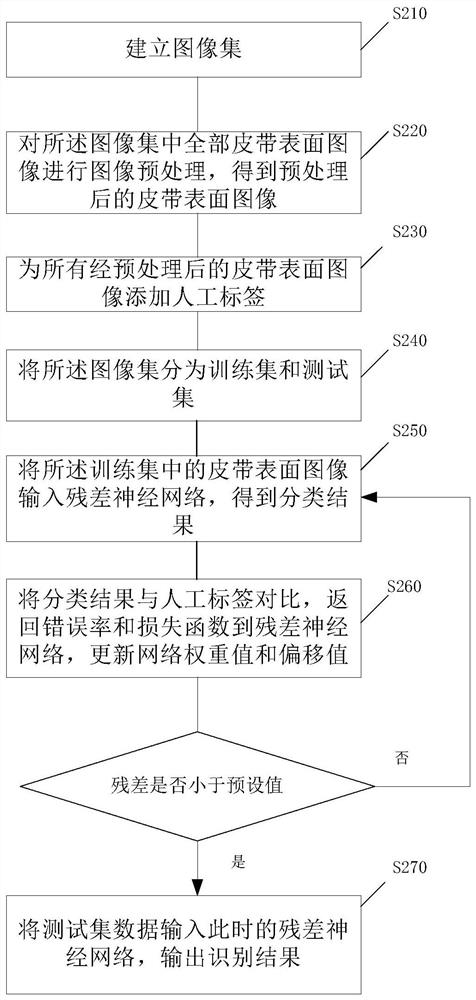

[0048] see figure 1 , is a step diagram of the method for detecting the surface state of a belt conveyor based on a convolutional neural network in this application;

[0049] Depend on figure 1 It can be seen that the embodiment of the present application provides a method for detecting the surface state of a belt conveyor based on a convolutional neural network, including the following steps:

[0050] S100: acquiring a belt surface image of a preset area during the operation of the belt conveyor;

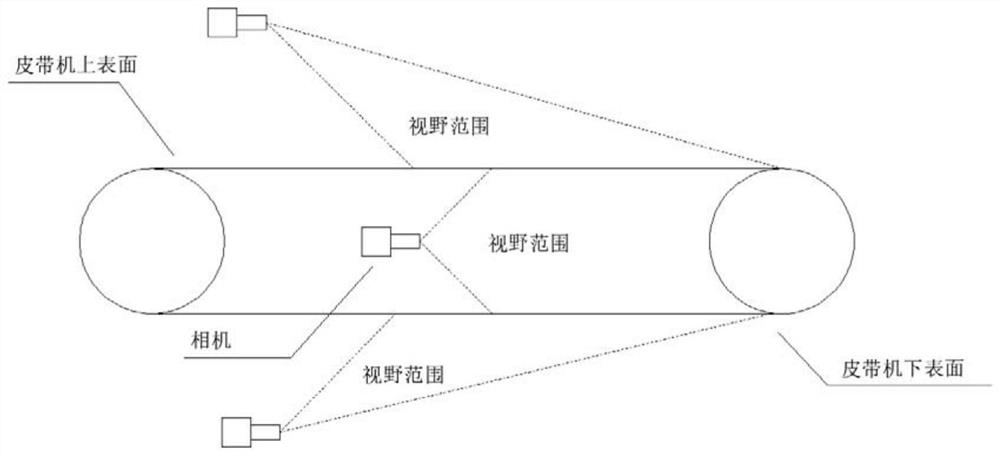

[0051] In this embodiment, the belt surface image can be collected in real time, and the collected belt surface image can be transmitted to the on-site industrial computer or the computer in the central control room for analysis and processing to determine whether the surface state of the current belt conveyor belt is abnormal ; The process of executing step S100 can usually be completed by using a camera, such as figure 2 In the working scene shown, the camera can be set above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com