Method and system for thermally connecting a heat source of a battery system to a heat sink of a battery system

A technology for battery systems and heat sinks, applied in the field of heat sinks, can solve problems such as expensive and no longer meaningful, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

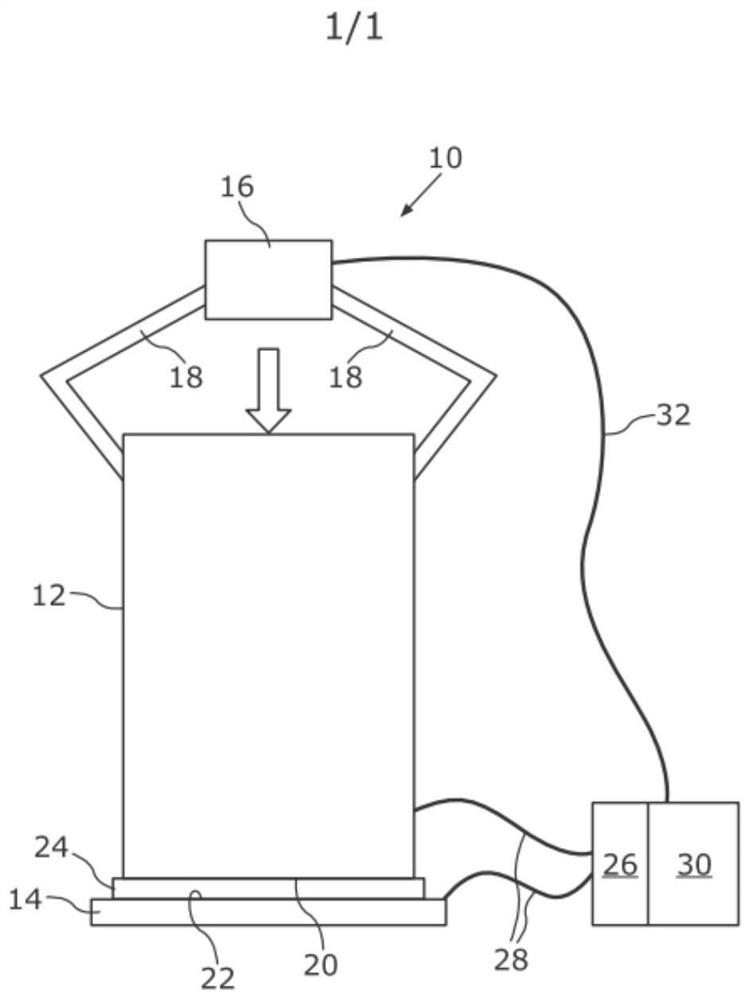

[0029] In the only illustration, a system 10 for thermally connecting battery cells 12 to a cooling plate 14 of a battery system (not further shown) is shown schematically. The battery cells 12 and the cooling plate 14 in the following explanations represent only exemplary examples of possible heat sources or cooling fins for use in the battery system.

[0030] The system 10 includes a positioning device 16 in the form of a robot arm or similar, designed to use a corresponding arm 18 to carry out a positioning process in which the pressing The electrically insulating heat conducting material 24 arranged between the electrically conductive housing surface 20 of the battery cell 12 and the electrically conductive heat transfer surface 22 of the cooling plate 14 serving as a heat sink reduces the The distance between the electrically conductive housing surface 20 and the electrically conductive heat transfer surface 22 . For this purpose, the positioning device 16 can grasp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com