Polyaryl-ether-ketone viscosity regulator synthesized based on A2+B3 type monomer reaction and method therefor

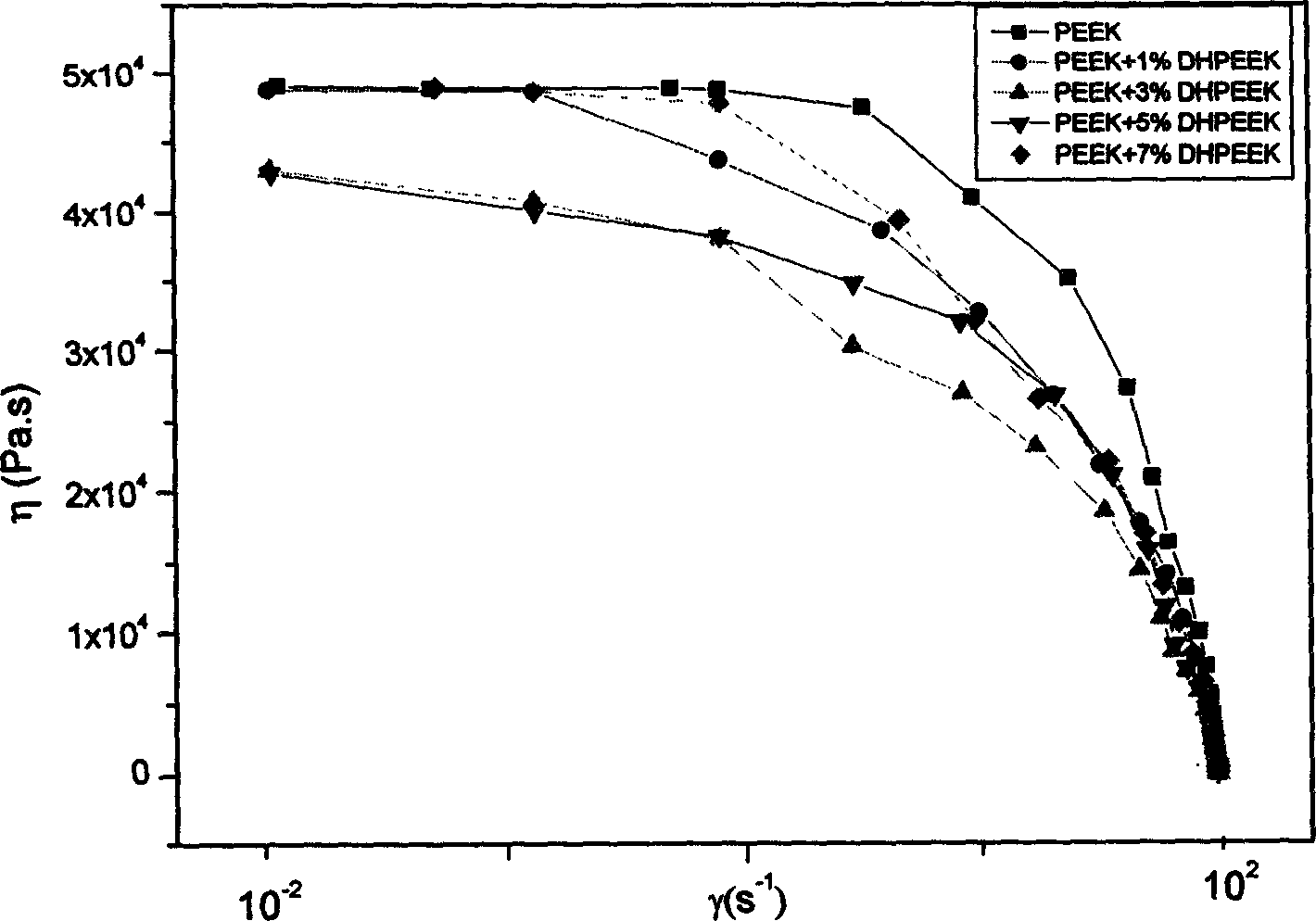

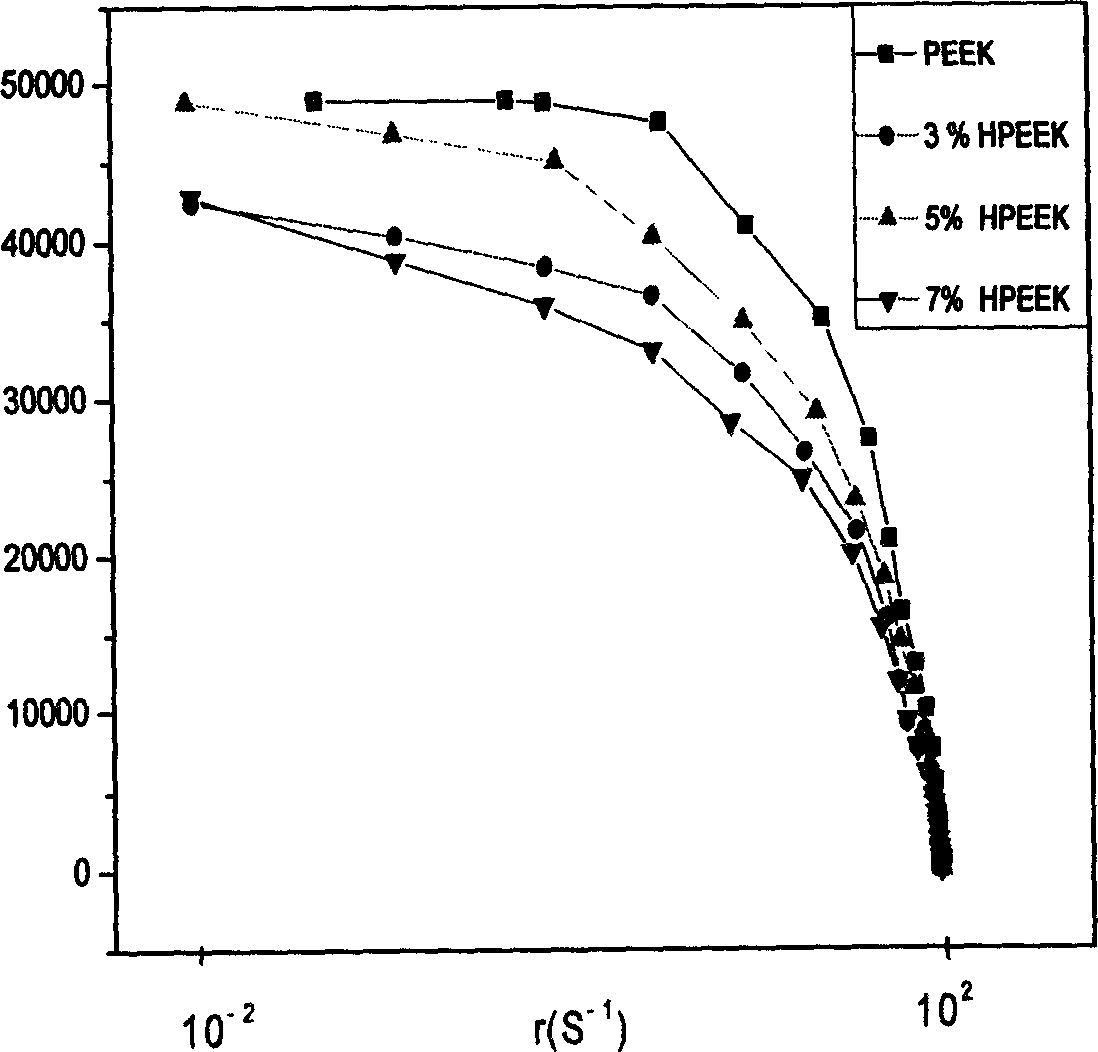

A technology of viscosity modifier and polyaryletherketone, which is applied in the field of hyperbranched polyaryletherketone materials and its synthesis, can solve the problems of reducing the solvent resistance and thermal stability of the blend, and damaging the structural properties of the material, and achieves Solvent resistance and thermal stability, melt viscosity reduction, melt viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Synthesis of fluorine-terminated hyperbranched polyetheretherketone (HPEEK-F)

[0032] Will B 3Type monomer 1,3,5-tris[4-(4-fluorobenzoyl)phenoxy]benzene 7.21g (0.01mol), hydroquinone 0.792g (0.0072mol), anhydrous potassium carbonate 1.04g ( 0.0076mol), 31g of diphenyl sulfone, with a solid content of 29%, were put into a three-necked flask equipped with a stirring device, fed with nitrogen, stirred, and heated. Salt formation temperature is controlled at 175°C for 3 hours, prepolymerization at 235°C for 1 hour, reaction at 280°C for 2 hours, and reaction at 300°C for 2 hours. Discharge into deionized water, pulverize, wash, dry, reflux with acetone for 3 to 5 times until there is no diphenyl sulfone in the filtrate, then wash with methanol for 2 times, heat filter to remove small molecular weight hyperbranched polymers, dry, 6.5 g of hyperbranched polyether ether ketone (HPEEK-F) whose terminal group is terminated by fluorine was obtained, and the yield...

Embodiment 2

[0035] Example 2: Synthesis of hydroxyl-terminated hyperbranched polyetheretherketone (HPEEK-OH)

[0036] Will B 3 Type monomer 1,3,5-tris[4-(4-fluorobenzoyl)phenoxy]benzene 7.21g (0.01mol), hydroquinone 3.35g (0.03045mol), anhydrous potassium carbonate 4.2g ( 0.03045mol), 59g diphenyl sulfone, with a solid content of 25%, put into a three-necked flask equipped with a stirring device, nitrogen, stirring, heating. Salt-forming temperature is controlled at 175°C for 2 hours, prepolymerization at 235°C for 1 hour, reaction at 280°C for 2 hours, and reaction at 300°C for 0.5 hour. Discharge into acidic deionized water (pH value 6.5-7), crush, wash, dry, reflux 3-5 times with acetone until there is no diphenyl sulfone in the filtrate, wash 2 times with methanol, and remove small particles by hot filtration. The molecular weight of the hyperbranched polymer was dried to obtain 7.6 g of hyperbranched polyether ether ketone (HPEEK-OH) whose terminal group was terminated by a hydroxy...

Embodiment 3

[0039] Example 3: Synthesis of fluorine-terminated hyperbranched polyether ether ether ketone (HPEEEK-F)

[0040] Synthetic method and process are the same as embodiment 1, change hydroquinone into 4,4'-dihydroxydiphenyl ether. A hyperbranched polyether ether ether ketone (HPEEEK-F) whose terminal group is terminated by fluorine was obtained, and the yield was 80%.

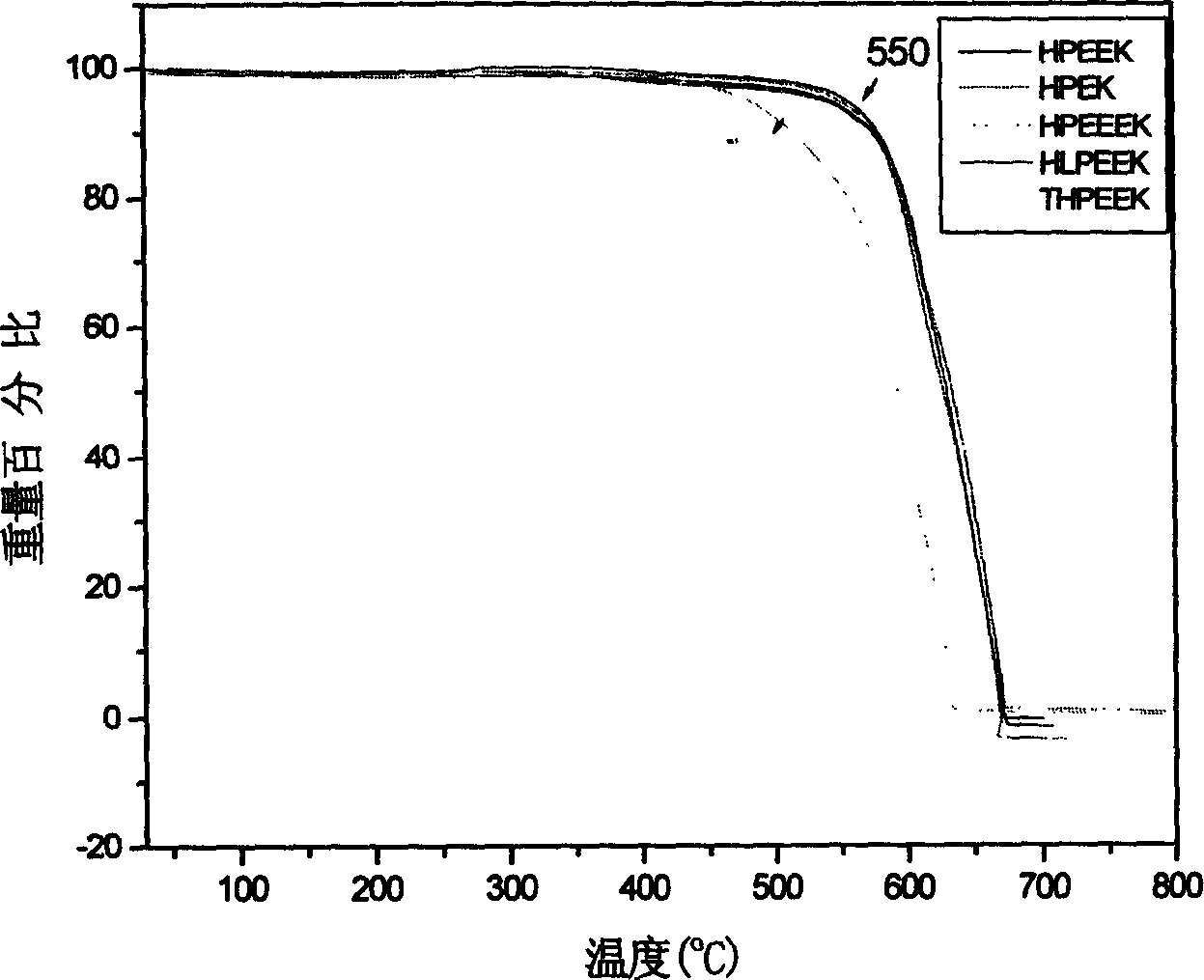

[0041] The glass transition temperature Tg of HPEEEK-F is 121°C and the viscosity η iv It is 0.15 (dL / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com