Motor bearing cover machining equipment

A technology for processing equipment and motor bearings, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of poor machining dimension runout guarantee, out of tolerance, etc., and achieve the effect of improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-7 The application is described in further detail.

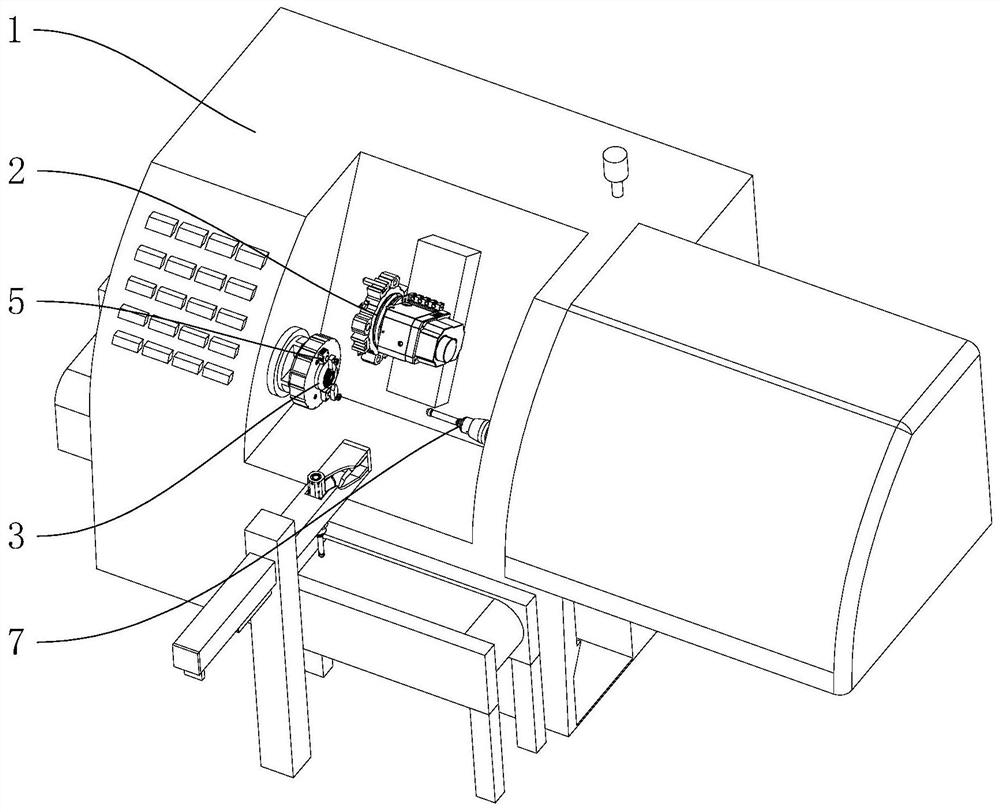

[0045] The embodiment of the present application discloses a motor bearing cover processing equipment. refer to figure 1 , The motor bearing cover processing equipment includes a lathe as a frame 1, a turning tool holder 2 arranged on one side of the frame 1, and an installation assembly installed on the lower side of the turning tool holder 2, and the installation assembly is used to fix the bearing cover. The installation assembly includes a positioning base 3 linked with the headstock in the frame 1, an outer circular pressing member 5 arranged on the positioning base 3, and an inner hole pressing member 7 oppositely arranged on the front side of the positioning base 3. A group of loading and unloading devices are also provided outside the frame 1 for automatically installing the bearing cover on the positioning base 3 .

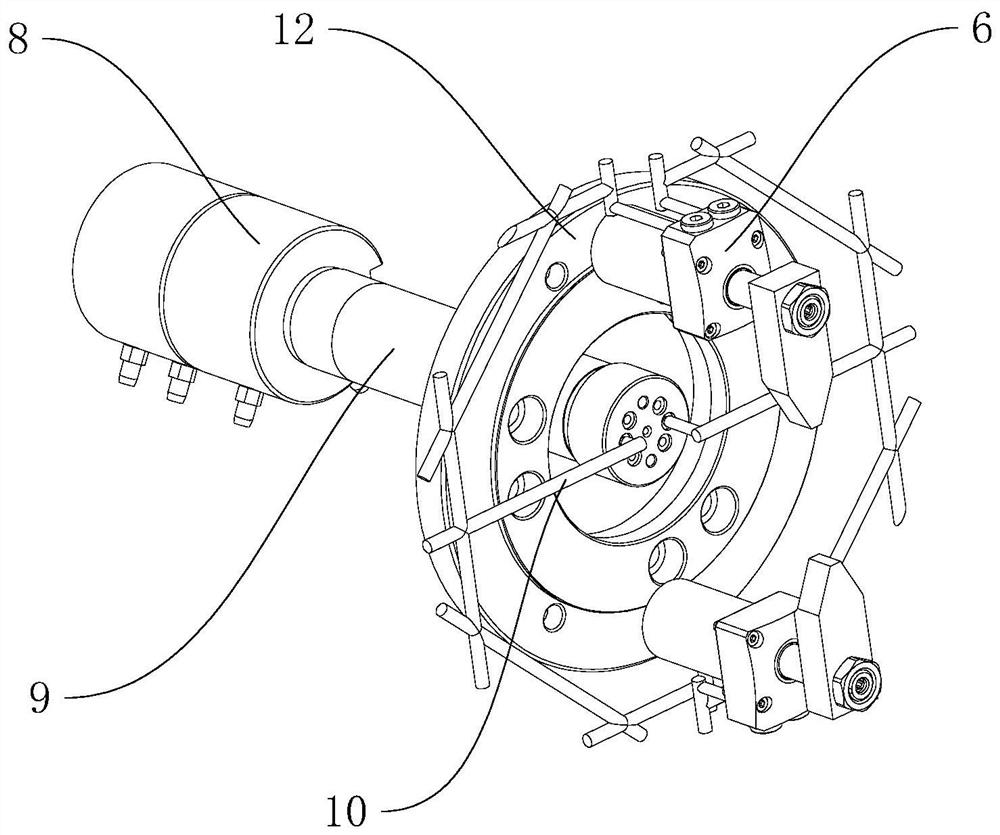

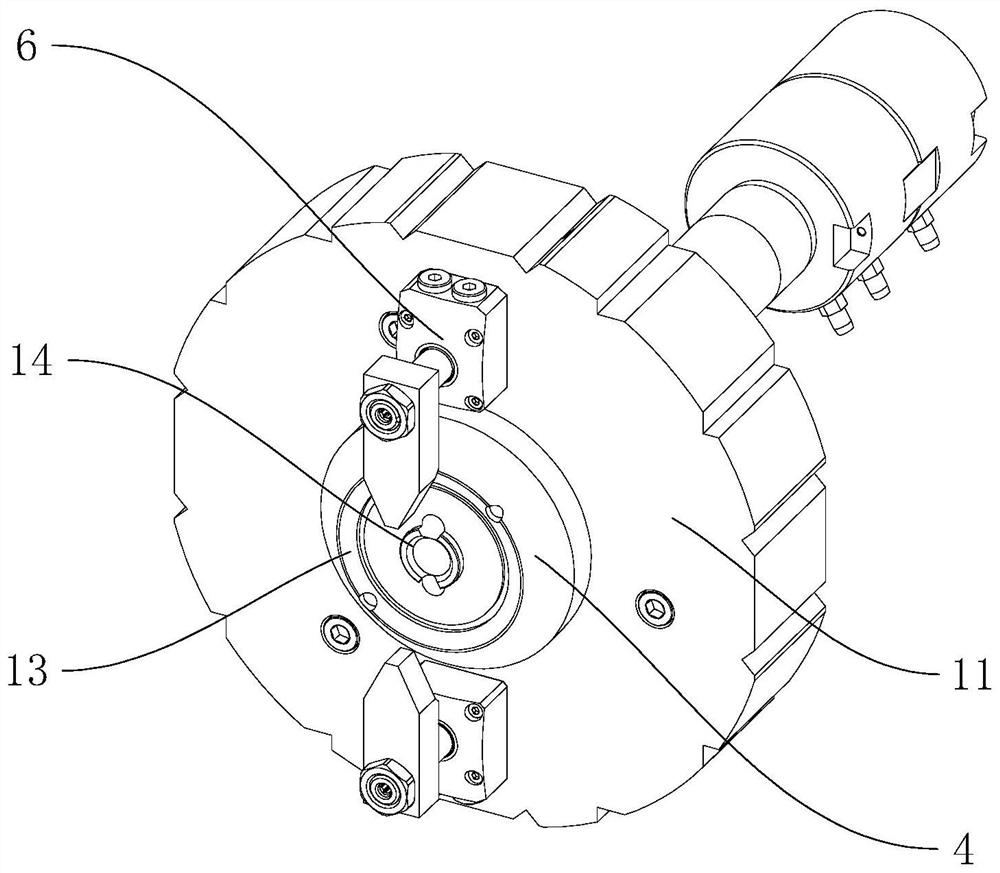

[0046] refer to figure 2 and image 3 The positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com