Fastening assembly with miniaturized electronic tag

A technology for fastening components and electronic tags, applied in the field of radio frequency, can solve the problem of temperature monitoring of components that cannot be fastened, and achieve the effects of high temperature monitoring accuracy, good metal resistance, and increased gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

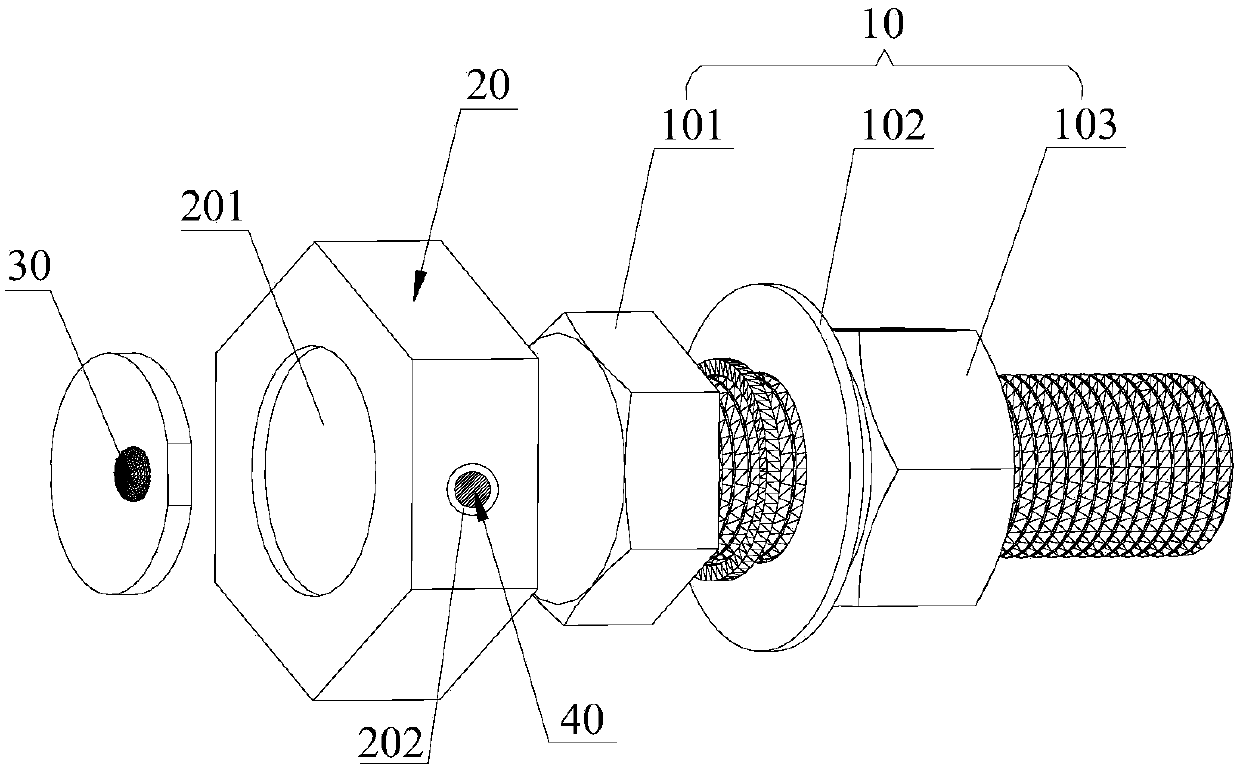

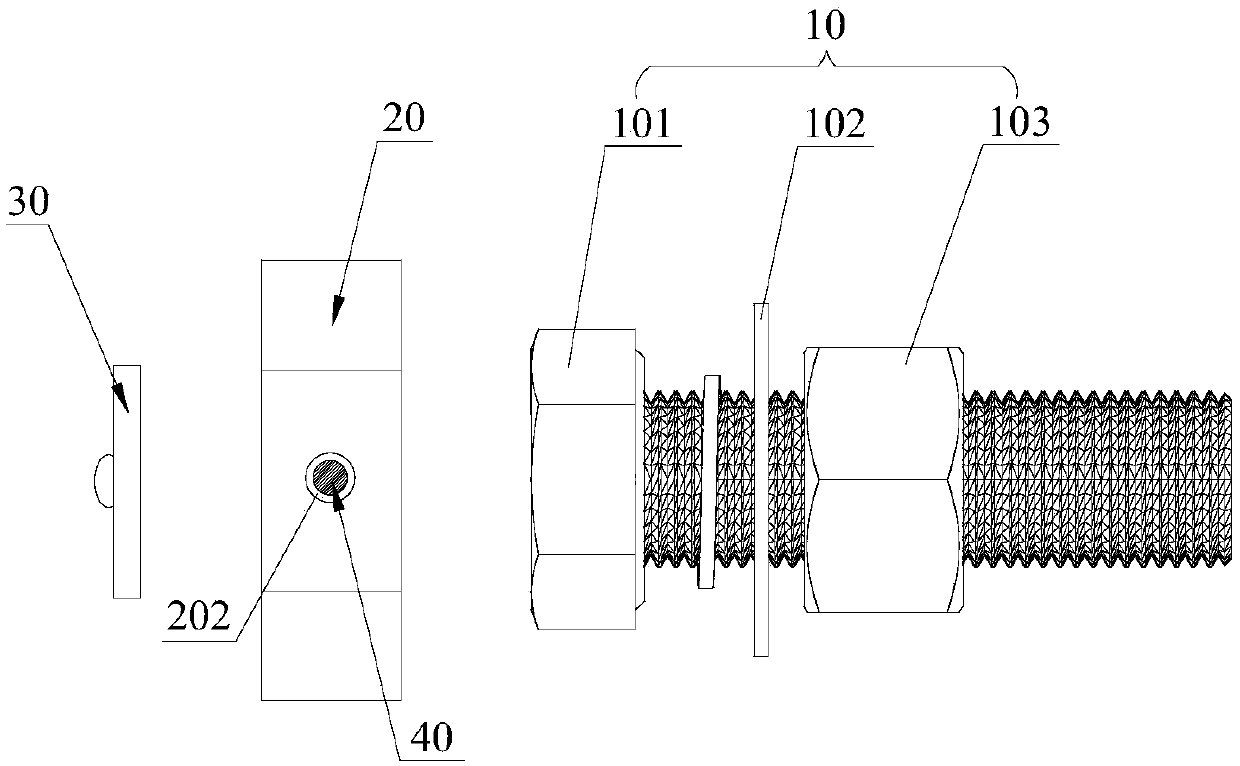

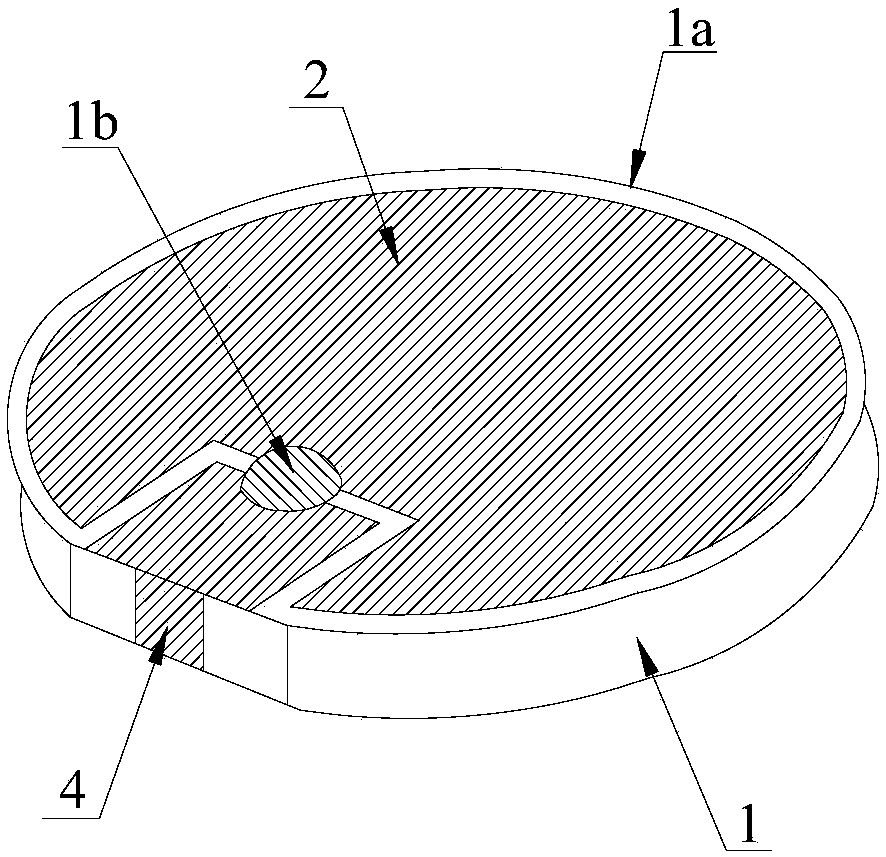

[0027] Such as Figure 1 to Figure 5 As shown, the fastening assembly with a miniaturized electronic tag provided in this embodiment includes a fastening assembly body 10 , a mounting part 20 and a miniaturized electronic tag 30 . The mounting member 20 is disposed at an end of the fastening assembly body 10 . The miniaturized electronic tag 30 is arranged on the mount 20. The miniaturized electronic tag 30 includes a miniaturized antenna 1a and a chip 1b connected to the power feeding part of the miniaturized antenna. The miniaturized antenna 1a includes a ceramic substrate 1, a radiation part 2, a reflector part 3 and connecting part 4. The radiation part 2 is formed on the first surface 11 of the ceramic substrate 1 . The reflection part 3 is formed on the second surface 12 of the ceramic substrate 1 . One end of the connecting portion 4 is electrically connected to the reflective portion 3, and the other end extends along the side wall of the ceramic substrate 1 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com