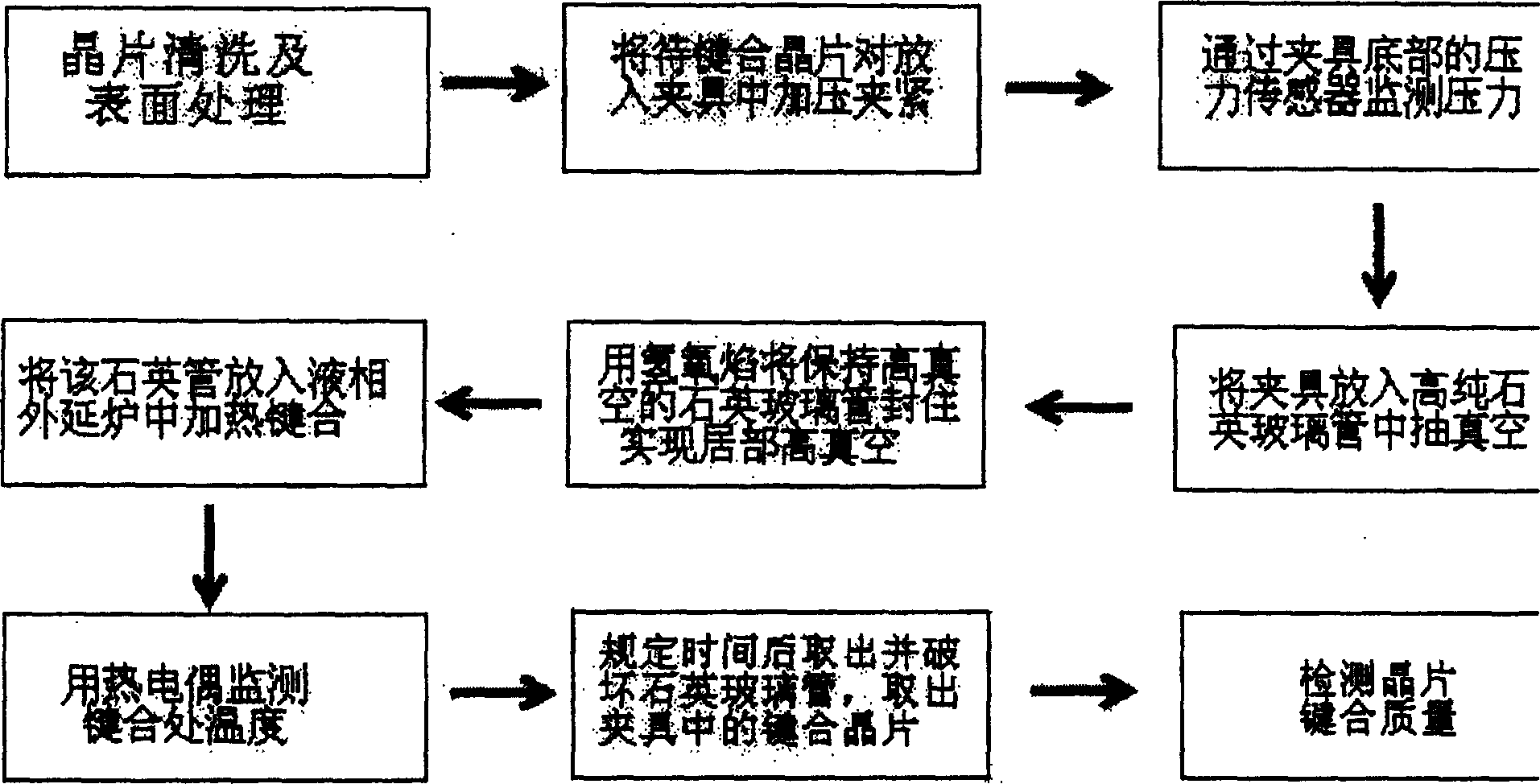

Method for bonding chip with different materials by sealed quartz tube

A quartz glass tube and wafer bonding technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of expensive wafer bonding systems and high system maintenance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

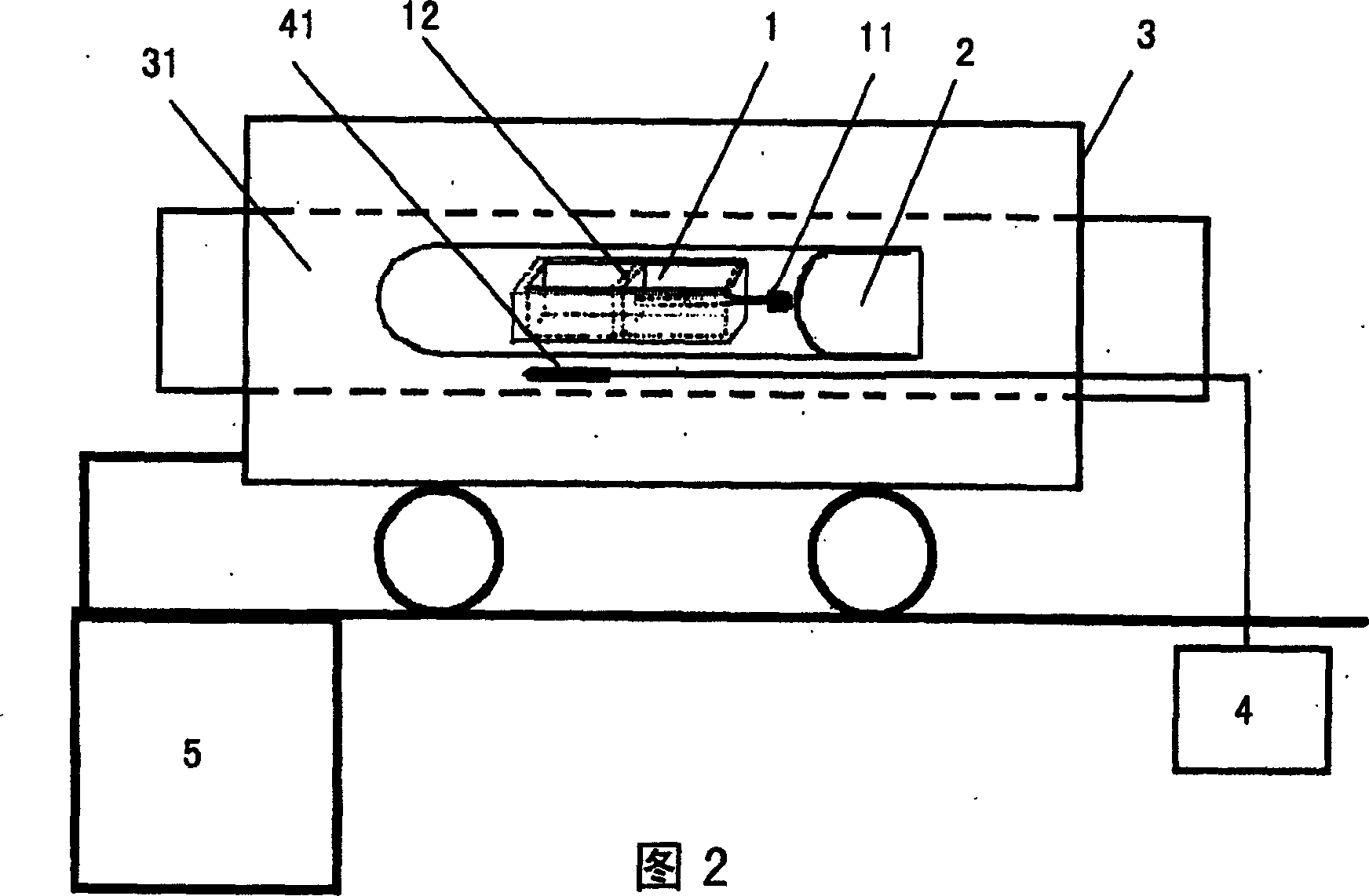

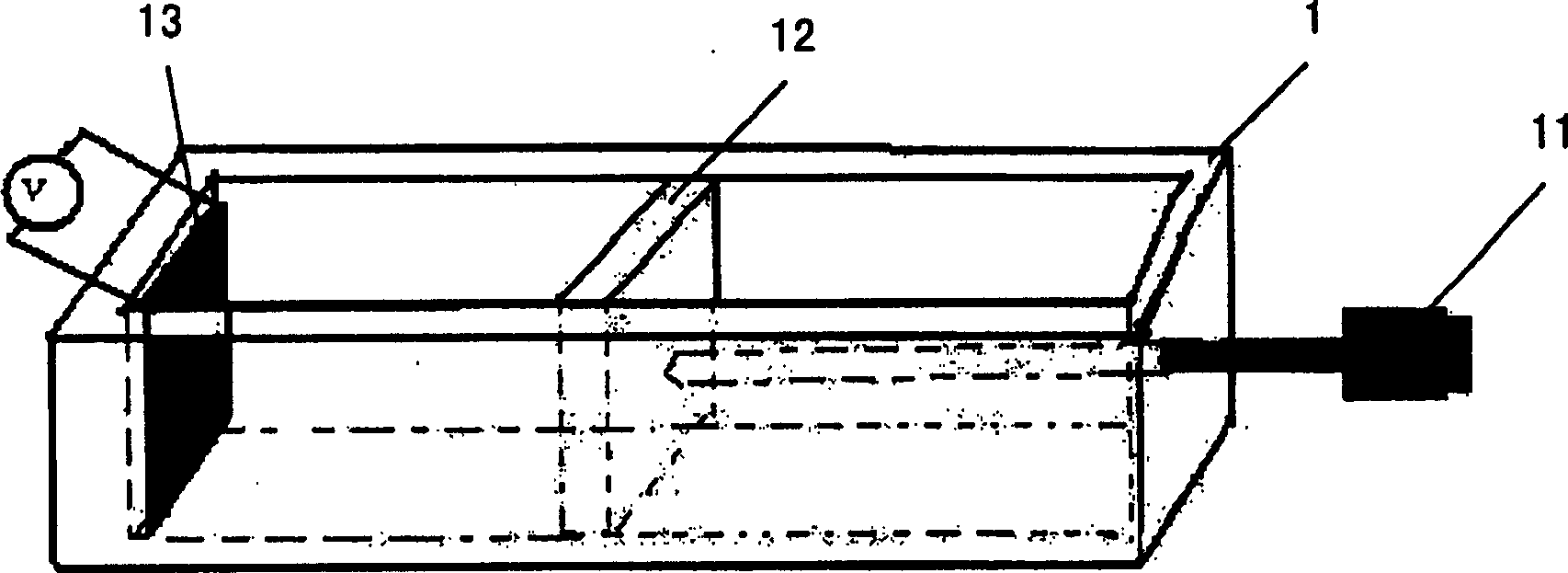

[0020] The present invention utilizes the sealed quartz glass tube to provide local high vacuum to realize the equipment connection mode of wafer bonding such as figure 1 Shown: the sealed quartz glass tube 2 is put into the inner cavity 31 of the liquid phase epitaxy furnace 3, the sealed quartz glass tube 2 is a high vacuum, and the bonding fixture 1 and the wafer (not shown in the figure) are packaged; A nickel-chromium-nickel-silicon thermocouple probe 41 is arranged below the glass tube 2, and the probe 41 is connected to the thermocouple temperature monitor 4; chamber heating temperature.

[0021] The preparatory work for sample processing of wafer bonding includes: cleaning - removing organic contamination; dissolving oxide layer; removing particulate metal contamination while passivating the surface of the wafer. The formulations of the standard wet chemical treatments used are as follows:

[0022] Sulphate H 2 SO 4 :H 2 o 2 (2:1 to 4:1) T=120-140°C, t=10min, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com