Quantitative split charging device for bulk flour

A quantitative packaging and equipment technology, which is applied in the field of bulk flour quantitative packaging equipment, can solve problems affecting the progress of flour packaging, and achieve the effect of saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

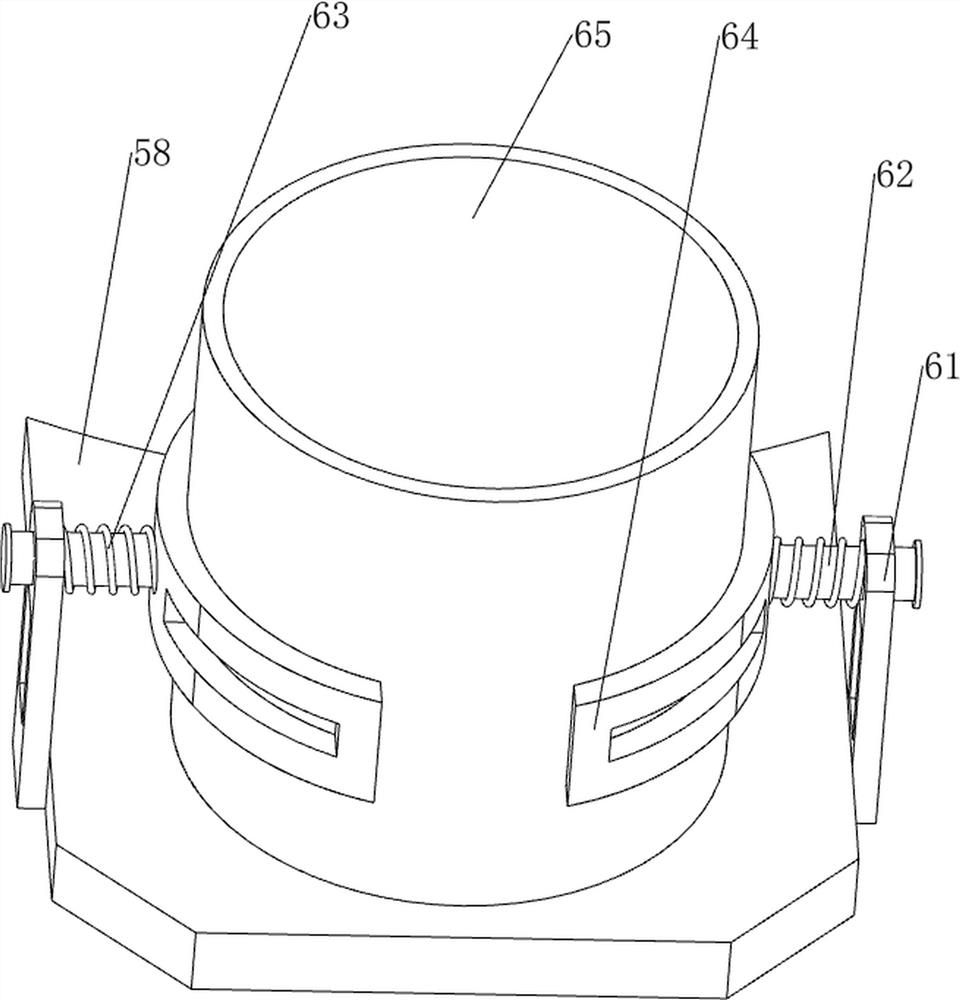

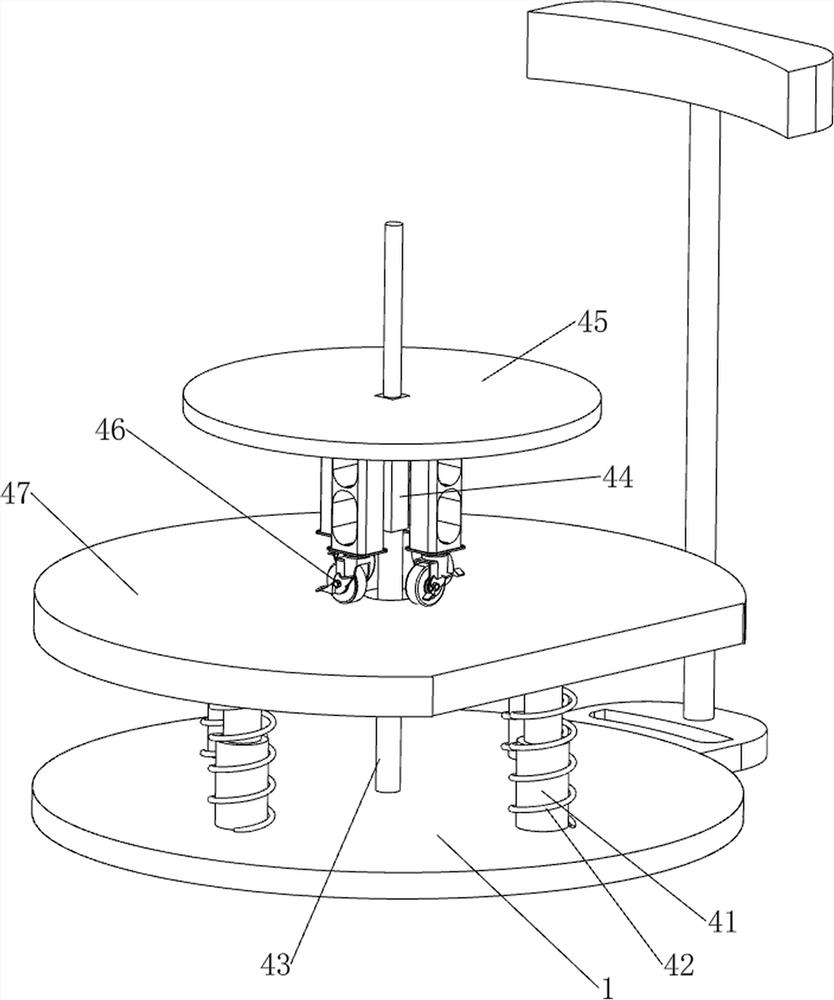

[0074] A kind of bulk flour quantitative dispensing equipment, such as figure 1 As shown, it includes a bottom frame 1, a material storage tank 2, a stirring mechanism 3, a rotating mechanism 4, a dumping mechanism 5 and a quantitative mechanism 6. The bottom frame 1 is provided with a material storage tank 2, and the inside of the material storage tank 2 is provided with a stirring mechanism. 3. The bottom frame 1 is provided with a rotating mechanism 4 in the middle, the rotating mechanism 4 is provided with a dumping mechanism 5 , and the dumping mechanism 5 is provided with a quantitative mechanism 6 .

[0075] When people need to carry out quantitative distribution of flour, they can use this bulk flour quantitative distribution equipment. First, people need to pour the flour into the storage tank 2, and then start the stirring mechanism 3, which rotates so that the flour can fall In the quantitative mechanism 6, when the quantitative mechanism 6 is filled with flour, man...

Embodiment 2

[0077] On the basis of Example 1, such as Figure 2-Figure 7 As shown, the stirring mechanism 3 includes a fixed plate 31, an electric rotating shaft 32, a flow limiting seat 33 and an agitating paddle 34. A fixed plate 31 is arranged between the tops of the left and right sides of the storage barrel 2, and an electric motor is installed in the middle of the fixed plate 31 in rotation. Revolving shaft 32, electric rotating shaft 32 bottoms are provided with flow-limiting seat 33, and flow-limiting seat 33 is rotatably connected with the middle inner wall of storage tank 2, and the four sides of flow-limiting seat 33 bottoms are all provided with stirring paddle 34.

[0078] People pour a large amount of flour in bulk into the storage barrel 2, and then start the electric shaft 32, and the rotation of the electric shaft 32 drives the flow limiting seat 33 to rotate, thereby driving the stirring paddle 34 to rotate, so that the stirring paddle 34 can stir the flour and push the f...

Embodiment 3

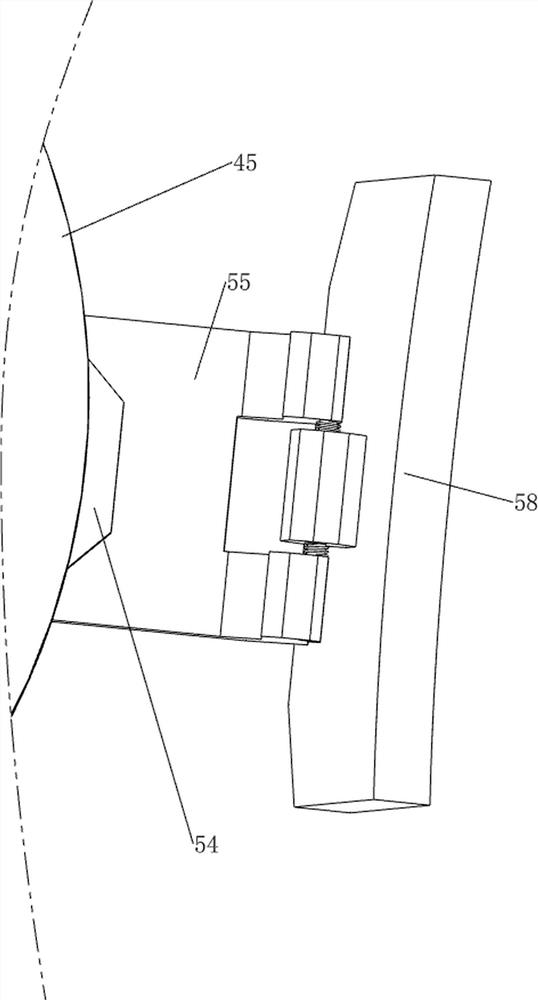

[0086] On the basis of Example 2, such as Figure 8 and Figure 9 As shown, the auxiliary mechanism 7 is also included, and the auxiliary mechanism 7 includes a bearing seat 71, a third rotating shaft 72, a pulley 73, a transmission belt 74, a mounting frame 75, a sliding sleeve 76, a cylinder 77, a rack 78, and a third spring 79 And spur gear 710, storage tank 2 upper left side is provided with bearing seat 71, bearing seat 71 lower side is provided with the 3rd rotating shaft 72, the 3rd rotating shaft 72 upper side and the first rotating shaft 43 upper side are all provided with belt pulley 73, two A transmission belt 74 is wound between the pulleys 73, a spur gear 710 is provided on the lower side of the third rotating shaft 72, a mounting frame 75 is provided on the left side of the bottom frame 1, and a sliding sleeve 76 is provided on the top left side of the mounting frame 75, and the rear of the sliding sleeve 76 is The side sliding type is provided with a rack 78, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com