Assembling method of electrostatic coalescence electrode sealing device

A sealing device and electrostatic coalescence technology, applied in the direction of electricity/magnetic dehydration/emulsification, etc., can solve the problems of poor properties, cumbersome structure, and increased floor space, so as to reduce production costs, improve dehydration efficiency, and save The effect of running power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

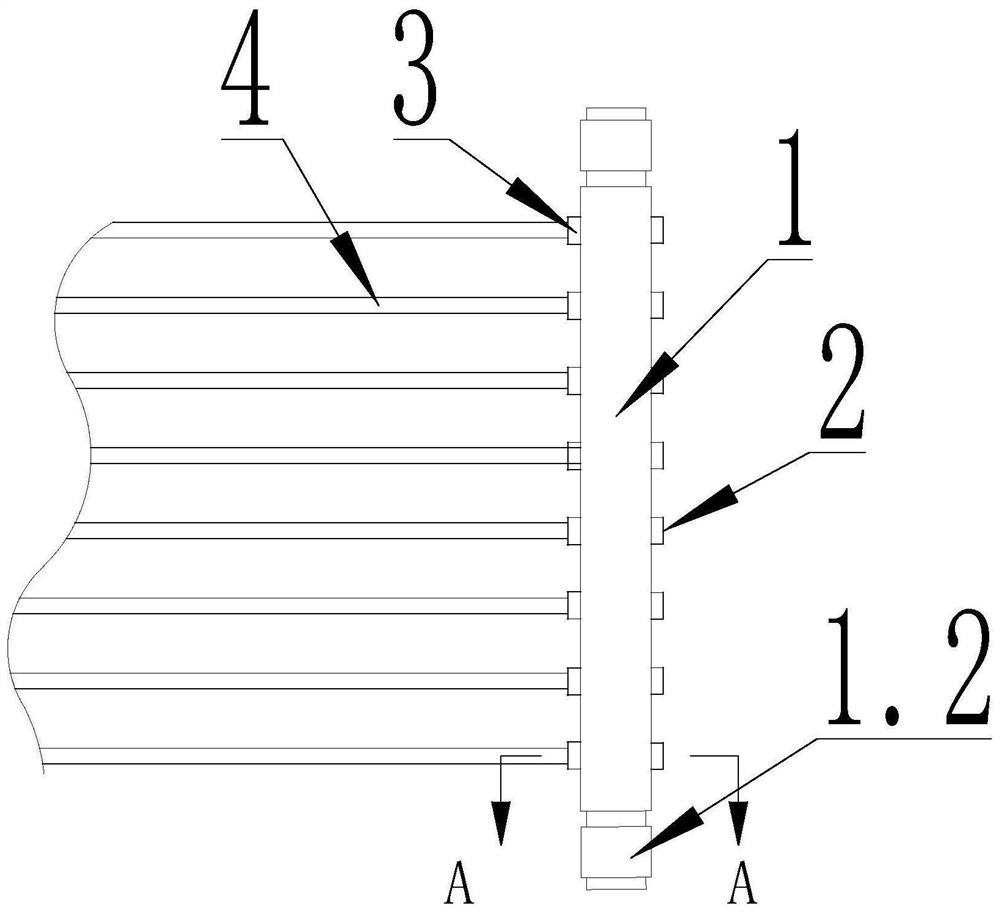

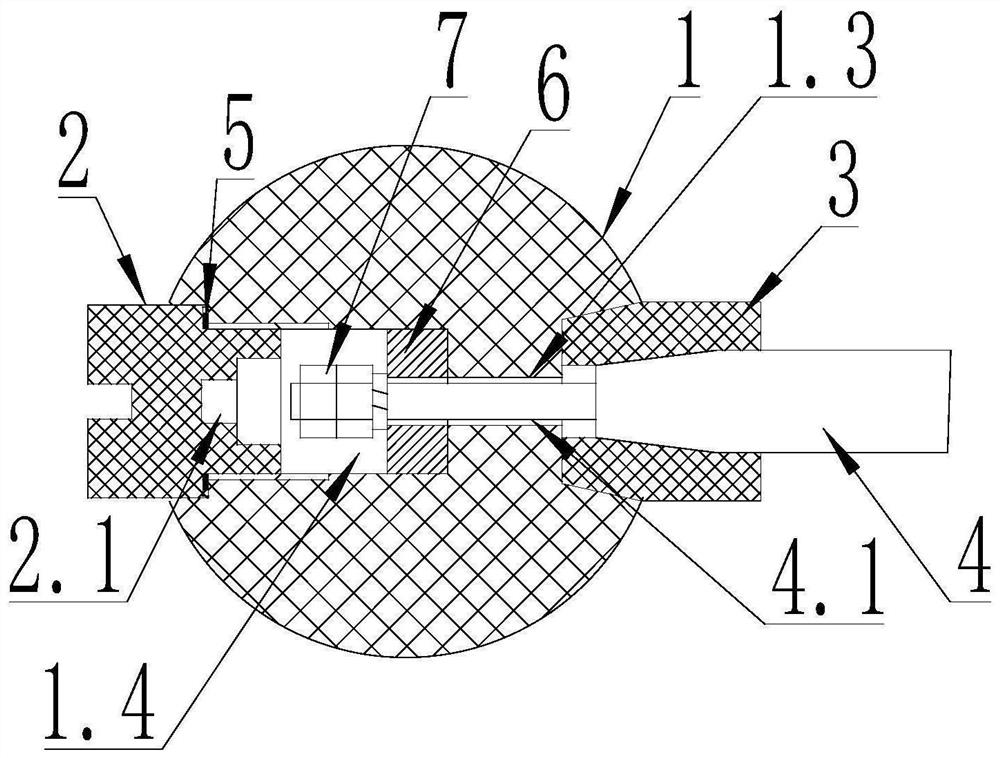

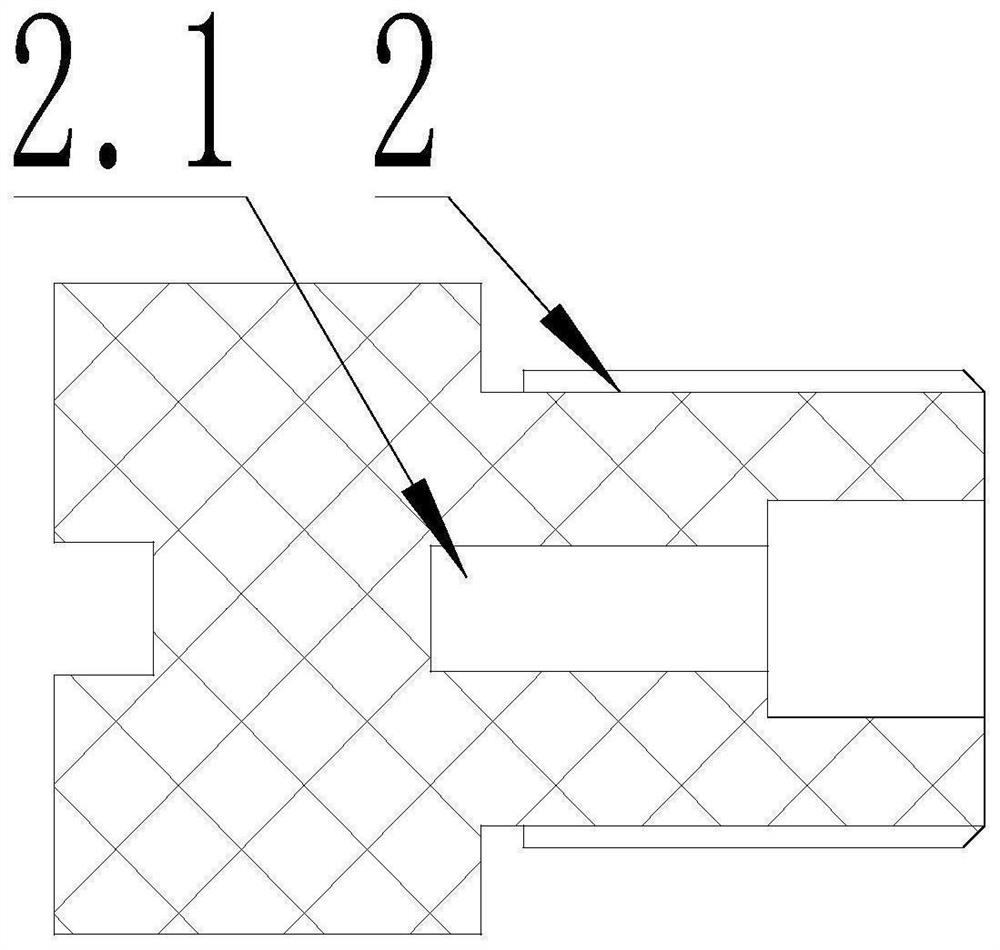

[0020] The center hole of the electrode manifold 1 is provided with a wire hole 1.1, the two ends of the electrode manifold 1 are provided with plugs 1.2, the electrode tube holes 1.3 are evenly distributed on the front side of the electrode manifold 1, and the sealing plugs 3 are arranged in the electrode tube holes 1.3 to seal An electrode tube jack 3.1 is set in the plug 3, and the electrode tube jack 3.1 communicates with the electrode tube hole 1.3, and a fixing hole 1.4 is set at the rear side of the electrode manifold 1 corresponding to the electrode tube hole 1.3, and the fixing hole 1.4 communicates with the electrode tube hole 1.3, The sealing bolt 2 is screwed in the fixing hole 1.4, the sealing ring 5 is set between the sealing bolt 2 and the front end of the fixing hole 1.4, the gasket 6 is set at the rear end of the fixing hole 1.4, the screw rod 4.1 is set in the middle of the front end of the electrode tube 4, and the electrode tube The front end of 4 is inserte...

Embodiment 2

[0022] The electrode tube hole 1.3 is formed by setting a cylindrical hole in the middle of the front end of the horn-shaped hole. The diameter of the front end of the horn-shaped hole is smaller than the diameter of the rear end, and the inner surface of the horn-shaped hole communicates with the surface of the electrode manifold 1. The front end of the shaped hole communicates with the fixing hole 1.4, and the diameter of the cylindrical hole is less than the diameter of the fixing hole 1.4.

Embodiment 3

[0024] The front end of the sealing plug 3 is set in the shape of a truncated cone, the diameter of the front end of the truncated cone is smaller than the diameter of the rear end, the front end of the sealing plug 3 is correspondingly inserted into the electrode tube hole 1.3, and the structure of the electrode tube insertion hole 3.1 is : A small cylindrical hole is set in the middle of the front end face of the sealing plug 3, a large cylindrical hole is arranged in the middle of the rear end face of the sealing plug 3, a conical hole is set between the small cylindrical hole and the large cylindrical hole, and the front end diameter of the conical hole is Smaller than the rear end diameter, the diameter of the small cylindrical hole is equal to the front end diameter of the conical hole, the diameter of the large cylindrical hole is equal to the rear end diameter of the conical hole, and the front end of the electrode tube 4 is set to be conical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com