one for co 2 Photocathode material for reduction of formic acid and preparation method thereof

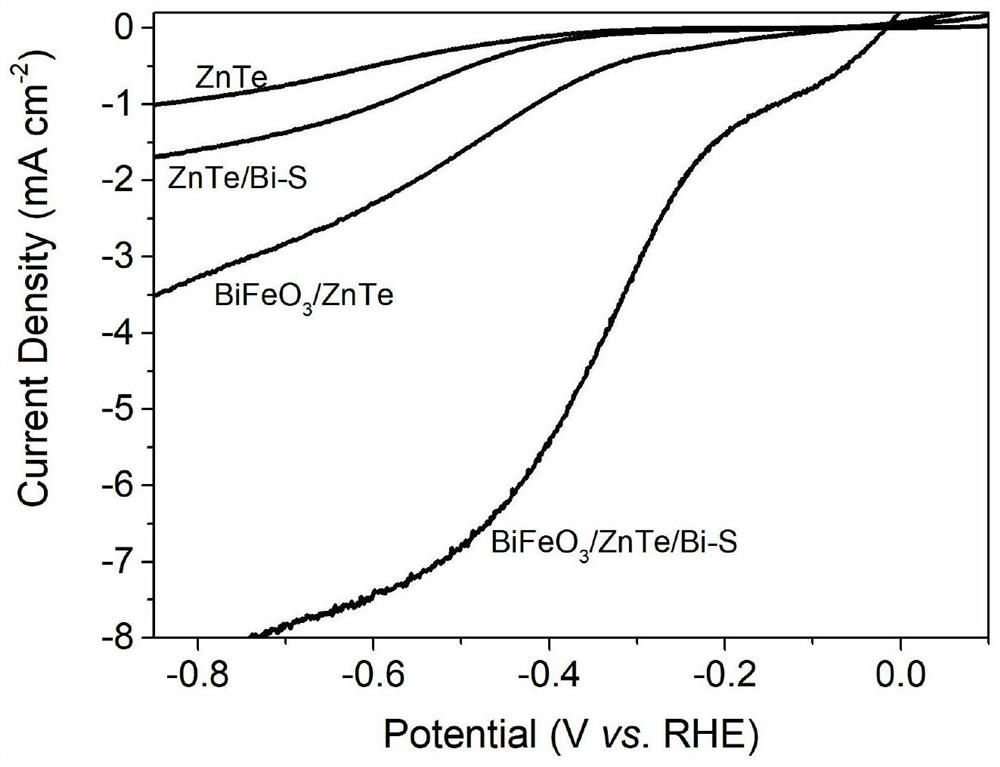

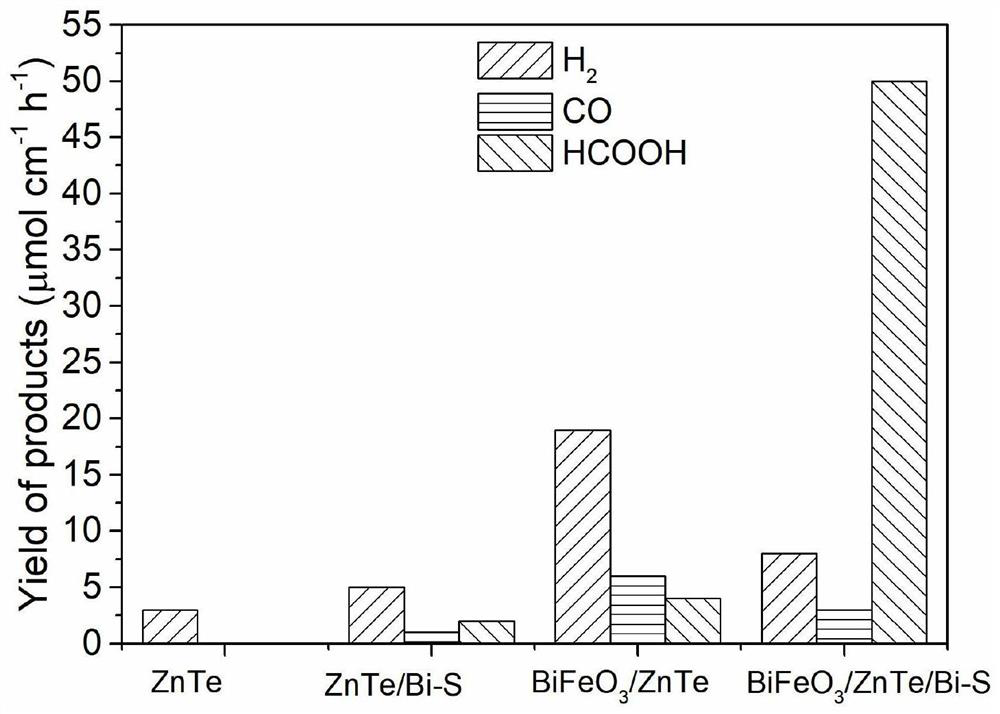

A photocathode, formic acid technology, applied in catalyst activation/preparation, chemical instruments and methods, inorganic raw material man-made filaments, etc., can solve the problems of decreased electron reduction ability, disadvantage, narrow scope of action, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for CO 2 A method for preparing a photocathode material for reducing formic acid, comprising the following steps;

[0029] mixing bismuth nitrate, ferric nitrate, citric acid, water and polyvinylpyrrolidone to obtain a spinning solution;

[0030] The polyvinyl alcohol aqueous solution is spin-coated onto the FTO surface to obtain a spinning substrate;

[0031] performing electrospinning on the surface of the spinning substrate by using the spinning solution to obtain three-dimensional nanofibers;

[0032] The three-dimensional nanofibers were calcined to obtain BiFeO 3 Nanofiber photoelectrodes;

[0033] With the BiFeO 3 The nanofiber optoelectronic electrode is used as the substrate, and ZnTe is used as the evaporation source to conduct evaporation coating to obtain ZnTe-loaded BiFeO 3 electrode;

[0034] BiCl3 , thioacetamide and dimethylformamide were mixed, and the ZnTe-supported BiFeO 3 The electrode is subjected to hy...

Embodiment 1

[0056] Weigh 0.78g of bismuth nitrate, 0.48g of ferric nitrate and 0.1g of citric acid respectively, add them into 10mL of deionized water, and stir to dissolve. Then 0.6 g of polyvinylpyrrolidone was added and stirred overnight to obtain a spinning solution. The FTO glass was fixed on the drum of the electrospinning device, and the aqueous solution of polyvinyl alcohol was spin-coated on the FTO surface before spinning to enhance the adhesion of FTO. Pour the spinning solution into the syringe, and set the parameters of the electrospinning process: the spinning voltage is 20kV, the drum speed is 150r / min, and the propulsion speed is 2mm / h, and three-dimensional nanofibers are obtained. Subsequently, the fiber was taken out and placed in a muffle furnace at 700°C for calcination for 5 hours to obtain BiFeO 3 nanofiber photoelectrode; the above BiFeO 3 The nanofiber photoelectrode is fixed on the substrate of the thermal evaporation coating machine, with ZnTe as the evaporati...

Embodiment 2

[0062] Weigh 1.17g of bismuth nitrate, 0.72g of ferric nitrate and 0.2g of citric acid respectively, add them into 10mL of deionized water, and stir to dissolve. Then 0.8 g of polyvinylpyrrolidone was added and stirred overnight to obtain a spinning solution. The FTO glass was fixed on the drum of the electrospinning device, and the aqueous solution of polyvinyl alcohol was spin-coated on the FTO surface before spinning to enhance the adhesion of FTO. Pour the spinning solution into the syringe, and set the parameters of the electrospinning process: spinning voltage 18kV, drum speed 200r / min, and propulsion speed 2mm / h, to obtain three-dimensional nanofibers. Subsequently, the fiber was taken out and placed in a muffle furnace at 800°C for calcination for 3 hours to obtain BiFeO3 nanofiber photoelectrode; the above BiFeO 3 The nanofiber photoelectrode is fixed on the substrate of the thermal evaporation coating machine, with ZnTe as the evaporation source, the vacuum in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com