Roadbed compactness detection device for road engineering detection

A technology for road engineering and detection device, which is applied to heating devices, infrastructure engineering, and on-site foundation soil survey, etc. The effect of improving the efficiency of borrowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

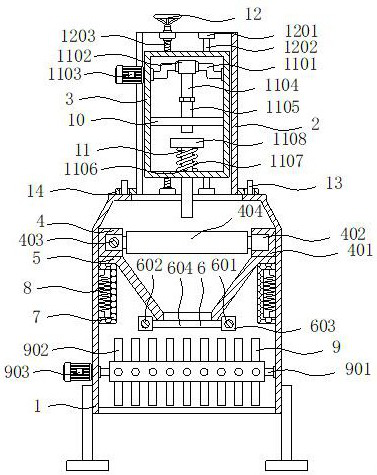

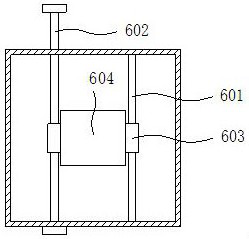

[0026] see Figure 1-7 , the present invention provides a technical solution: a roadbed compactness detection device for road engineering inspection, comprising a drying box 1, the top of the drying box 1 is provided with an opening, and the bottom of the drying box 1 is provided with a discharge port, The top of the drying box 1 is provided with a fixed shell 2, and the interior of the fixed shell 2 is provided with an organic case 3. The inner wall of the drying box 1 is fixedly equipped with a funnel frame 5, and the top of the funnel frame 5 is provided with a clamping mechanism 4, and the funnel frame 5 The bottom of the drying box 1 is provided with a sealing mechanism 6, and the inner walls of both sides of the drying box 1 are fixedly equipped with a dust cover 7, and the inner top and bottom of the two groups of dust cover 7 are fixedly installed with a heating wire 8, and the inside of the drying box 1 A stirring mechanism 9 is provided, a partition 10 is fixedly ins...

Embodiment 2

[0030] see Figure 1-7On the basis of Embodiment 1, the clamping mechanism 4 includes a fixed plate 401, a slider 402, a first threaded rod 403, a moving plate 404, a connecting rod 405 and a clamping plate 406, and the top of the funnel frame 5 is fixedly installed with two One set of fixed plates 401, the adjacent side walls of the two sets of fixed plates 401 are provided with chute, two sets of sliders 402 are slidably installed in the two sets of chute, and the front and rear sides of the chute of one set of fixed plate 401 are all rotatably installed There is a first threaded rod 403, and two sets of sliders 402 in one group of fixed plates 401 are screwed to the outer wall of the first threaded rod 403, and one end of the first threaded rod 403 runs through the fixed plate 401 and the front side of the drying box 1 And be fixedly installed with turning handle, turn the turning handle on the first threaded rod 403, turn the handle to drive the first threaded rod 403 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com