Novel modular temporary support assembly structure for loess tunnel with ultra-large cross section

A technology of loess tunnel and super large section is applied in the field of new modular temporary support assembly structure of super large section loess tunnel, which can solve the problems of easy occurrence of virtual welding, high energy consumption and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

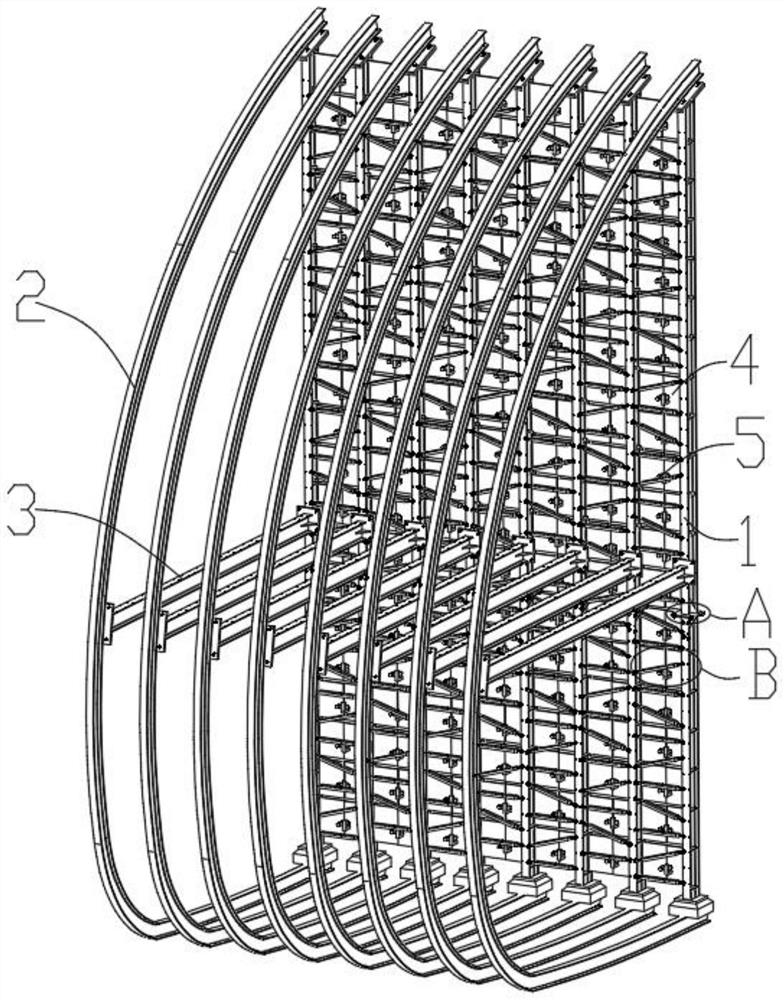

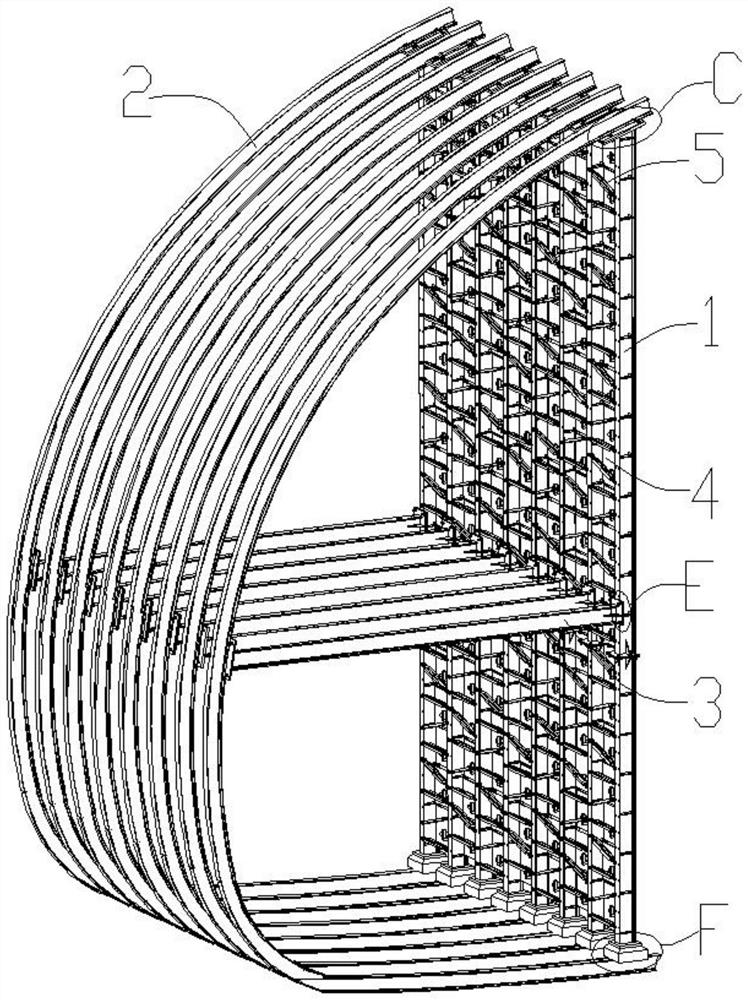

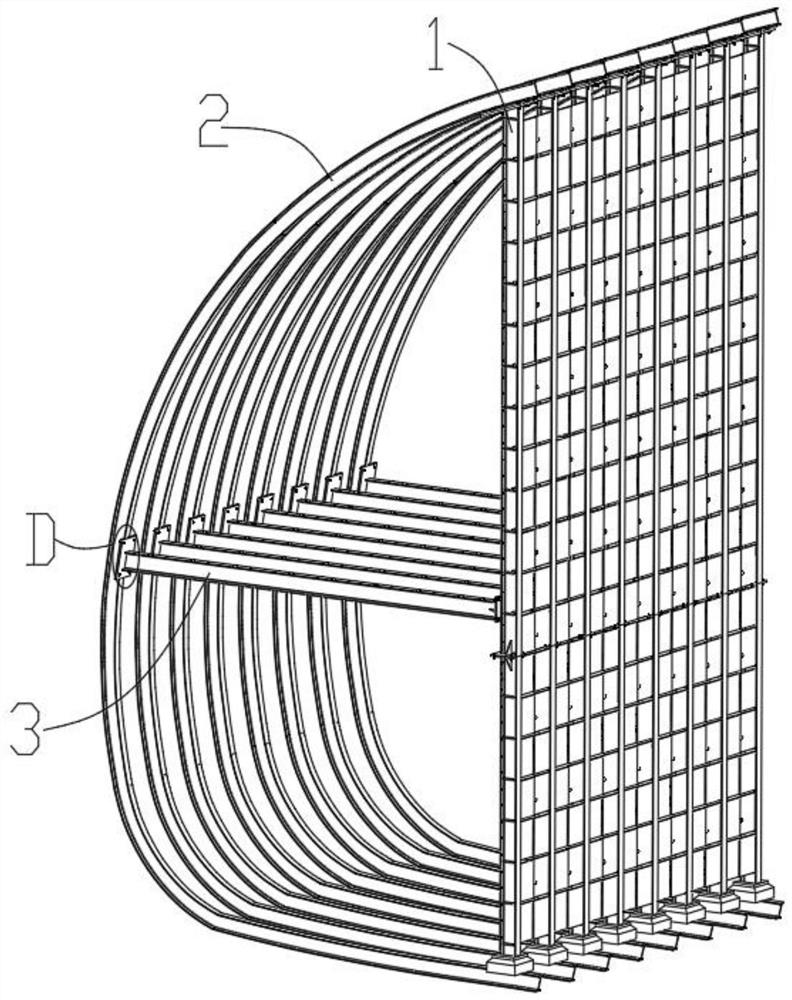

[0030] A new type of modular temporary support assembly structure for super large section loess tunnels, such as Figure 1-Figure 3 As shown, it is characterized in that it includes a vertical support 1, a ring support 2 and a temporary inverted arch 3, and the vertical supports 1 are detachably connected through a gate structure 4 and a tensioning structure 5, and the vertical The support 1 is detachably connected to the hoop support 2 , and the two ends of the temporary inverted arch 3 are detachably connected to the vertical support 1 and the hoop support 2 .

[0031] The vertical support 1, the hoop support 2 and the temporary inverted arch 3 are made of I-beam.

[0032] Such as Figure 6 As shown, the door structure 4 includes a left door panel 401 and a right door panel 402, and the left door panel 401 and the right door panel 402 are respectively connected to two adjacent vertical supports 1 by bolts. The door panels 402 are staggered and installed so that a gap is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com