Valve element structure of proportional reversing valve

A proportional reversing valve and valve core technology, applied in valve devices, multi-port valves, sliding valves, etc., can solve the problems of reduced overcurrent pressure and high flow control requirements, and achieve large overflow, stable flow output and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The spool structure of the proportional reversing valve described in the present invention can be made of the following materials, and is not limited to the following materials, such as common components such as spool, hydraulic matching system, and electric control device.

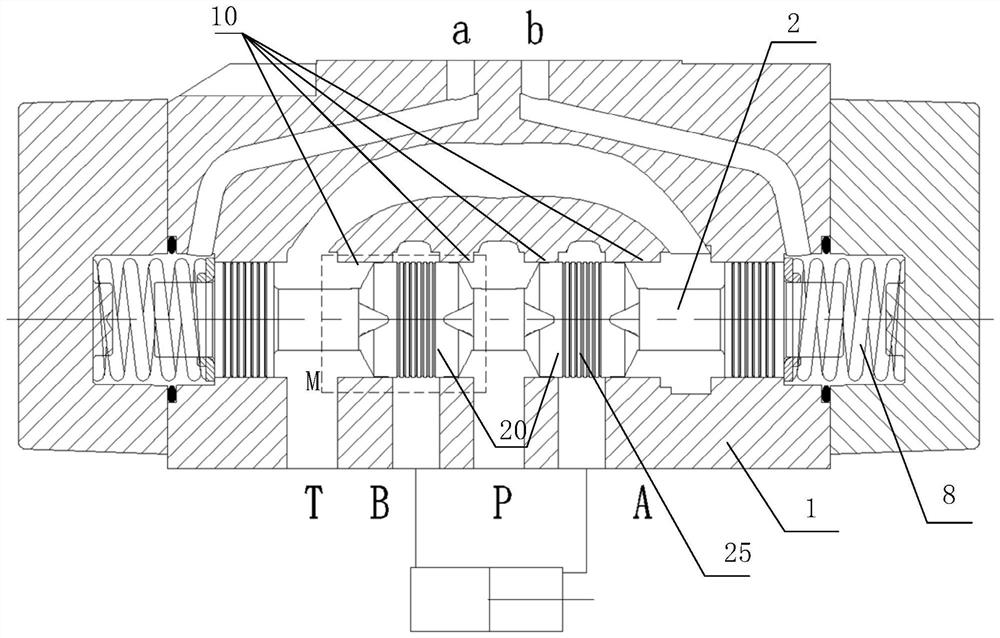

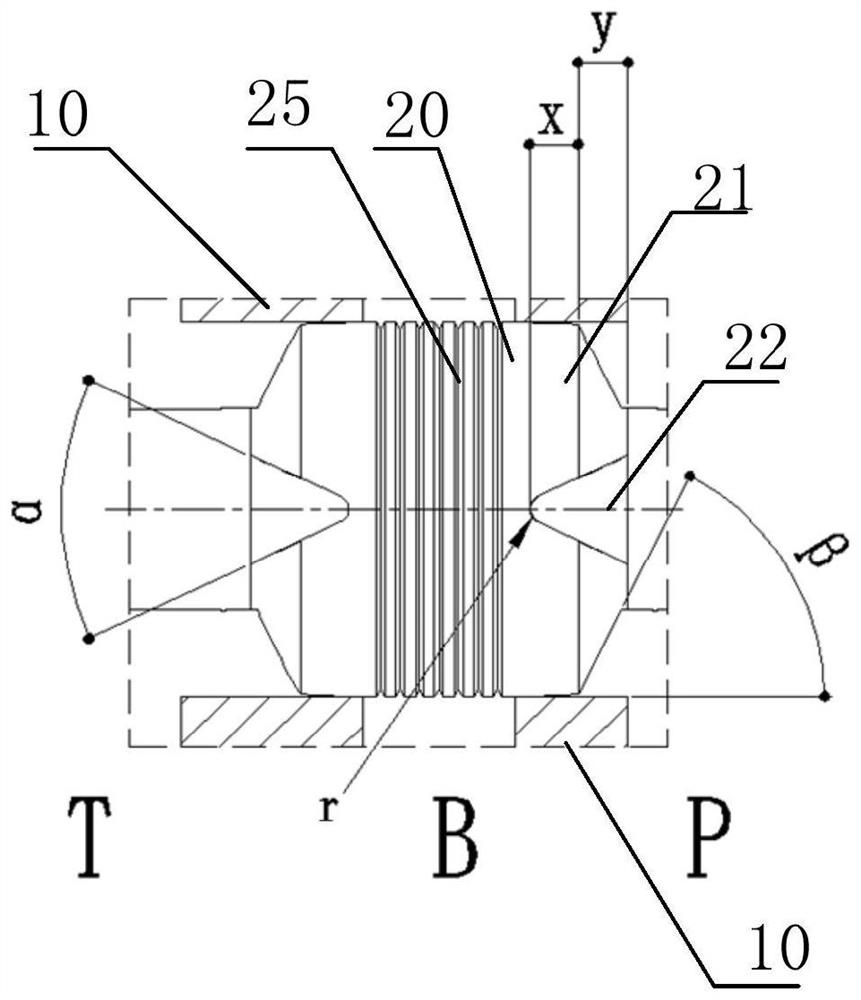

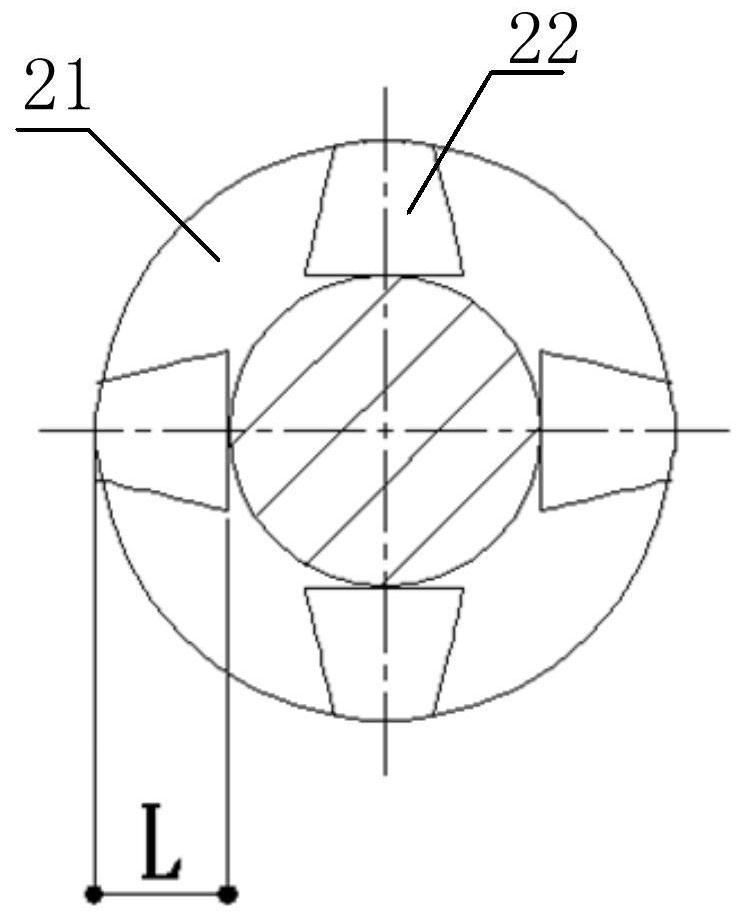

[0028] figure 1 It is a schematic diagram of the cross-sectional structure of the valve core structure of the proportional directional valve in the embodiment of the present invention in the neutral state; figure 2 for figure 1 Partial enlarged schematic diagram of middle M; this embodiment combines image 3 with Figure 4 Be explained.

[0029] The spool structure of the proportional reversing valve in the embodiment of the present invention is slidably installed in the housing 1, and the housing 1 is provided with a high-pressure oil port P and at least one working oil port (A and B). The housing 1 is provided with a slide hole 10, the valve core 2 is sleeved in the slide hole 10 and seals t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com