System and method for monitoring gas and temperature in transformer oil based on pure optical fiber sensing

A transformer oil and monitoring system technology, applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., can solve latent faults without preventive monitoring, lack of professional and comprehensive diagnosis, lack of real-time, effective In order to achieve maintenance-free operation, realize comprehensive online monitoring, improve effectiveness and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

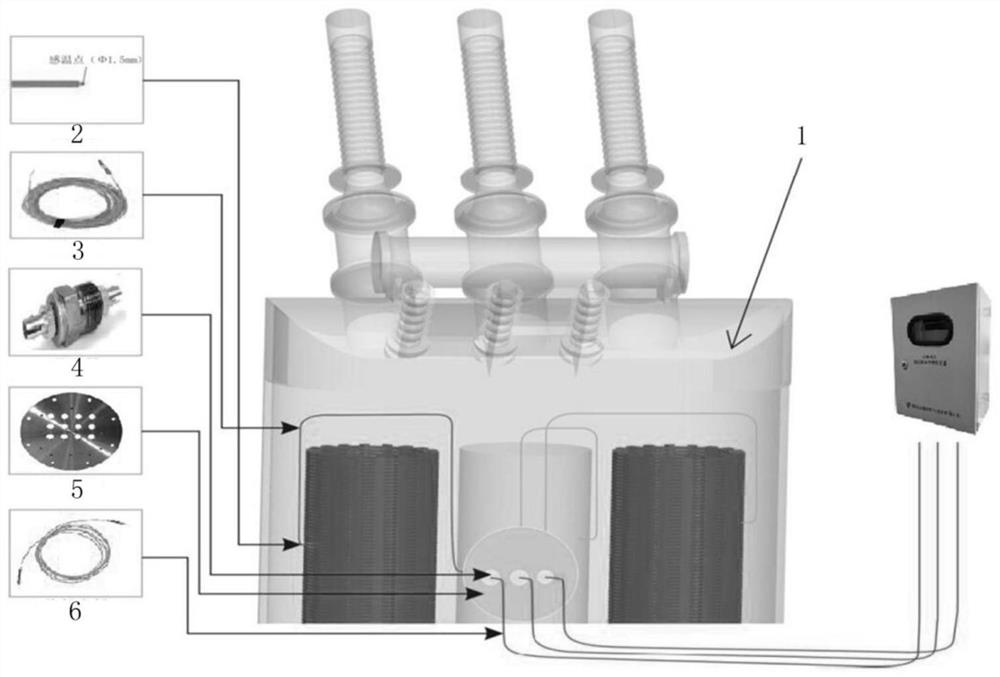

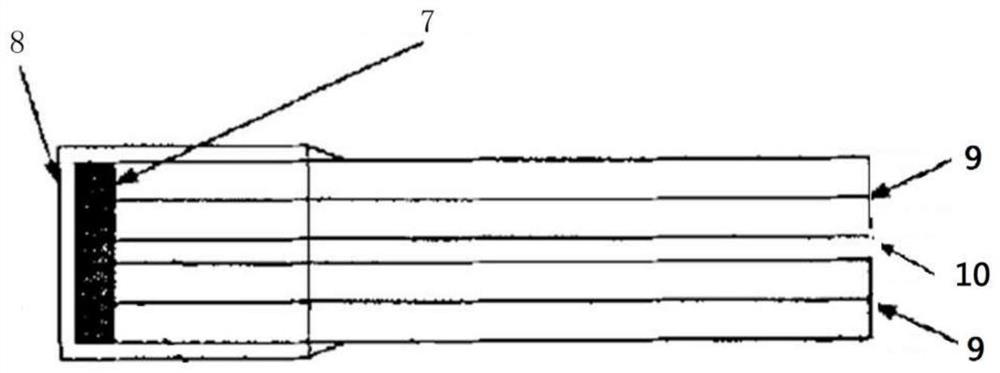

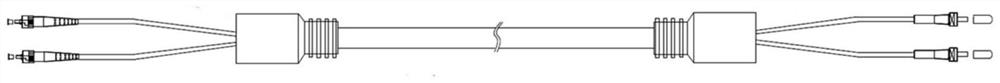

[0058] refer to figure 1 , a system and method for monitoring gas and temperature in transformer oil based on pure optical fiber sensing, including a sensor 2, an internal optical fiber 3, a penetrator 4, a flange 5, an external optical fiber 6 and a monitoring host. The sensor 2 includes a fluorescent optical fiber sensor and an evanescent field optical fiber hydrogen sensor. They are integrated with the internal optical fiber 3 installed inside the traction transformer 1. The probe of the sensor 2 is installed at the measurement point and connected to the flange installed on the internal optical fiber 3. On the penetrator 4 on the plate 5, the flange plate 5 is installed on the wall of the traction transformer 1, and the outside of the penetrator 4 is connected to the monitoring host through the external optical fiber 6 installed on the outside of the traction transformer 1 for analysis, diagnosis and analysis, and the detection The results are displayed on the local LCD scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com