Heat exchanger and fuel cell system

A fuel cell system and heat exchanger technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as poor performance of single cells, and achieve the goal of reducing types, volume, quantity and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

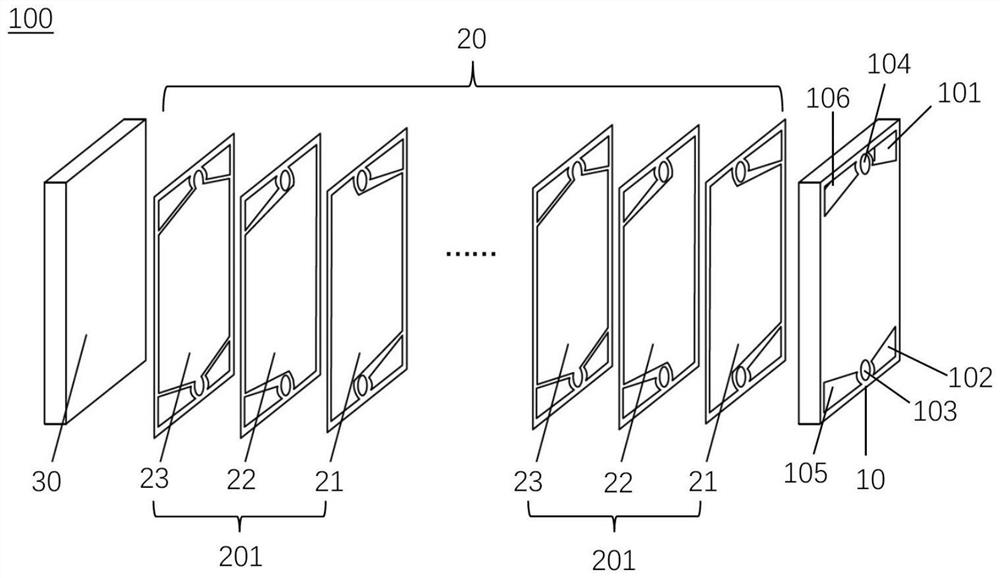

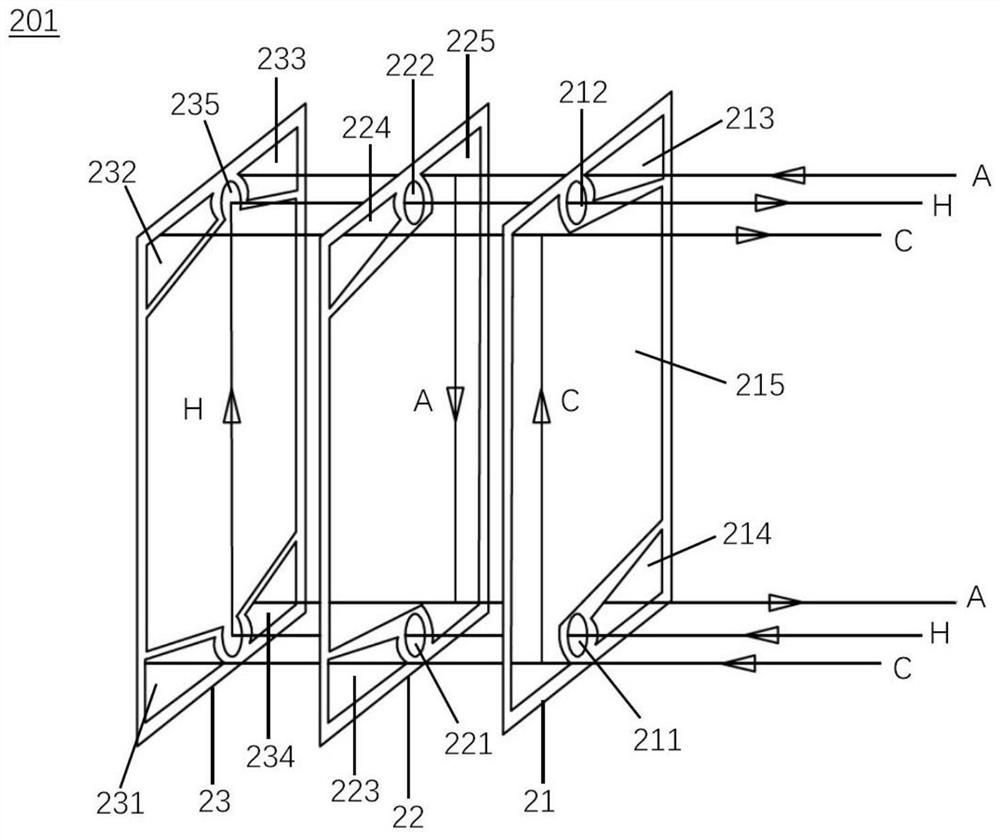

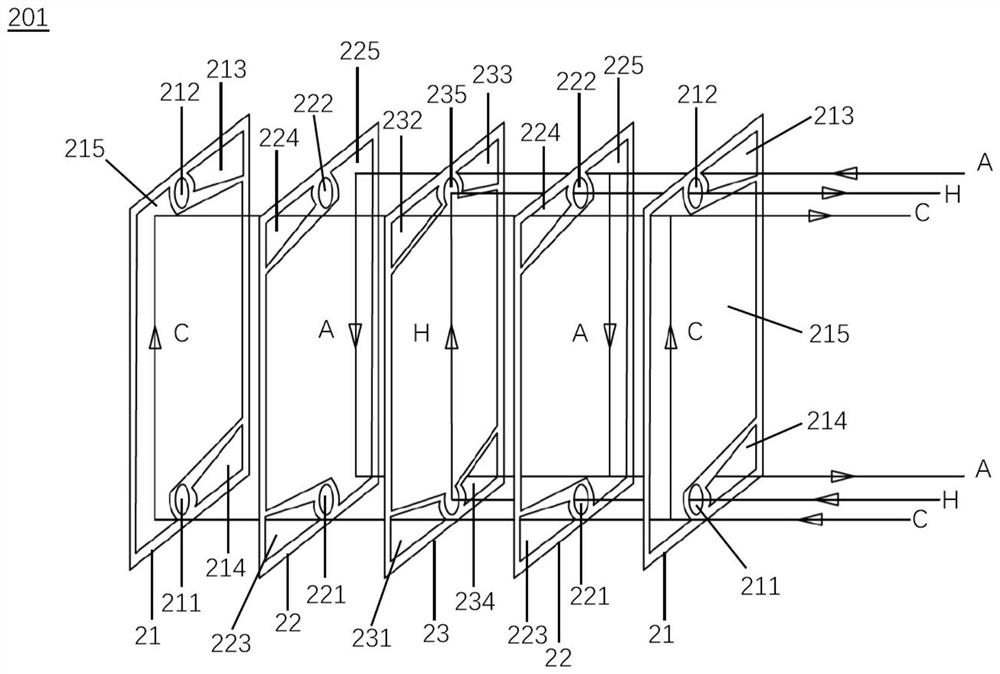

[0037] figure 1 is a schematic diagram of an exploded structure of a heat exchanger 100 according to an embodiment of the present invention. figure 2 is a schematic diagram of the heat exchange unit 201 of the heat exchanger 100 according to an embodiment of the present invention. Such as figure 1As shown, in one embodiment, the heat exchanger 100 includes a front end plate 10 , a heat exchange plate assembly 20 and a rear end plate 30 stacked in sequence. The front plate 10 is provided with n groups of inlets and outlets, and each group of inlets and outlets includes an inlet and an outlet for circulating the same medium. The heat exchange plate assembly 20 includes at least one heat exchange unit 201. Optionally, the number of heat exchange units 201 is determined according to the power of the fuel cell system. For example, when the power of the fuel cell system is large, several heat exchange units 201 are provided. The heat exchange unit 201 includes at least n flow fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com