Large horizontal force shear test device and test method for airport pavement seal

A shear test and horizontal force technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of peeling, restraint, insufficient anti-skid performance, etc., to reduce test errors and improve. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

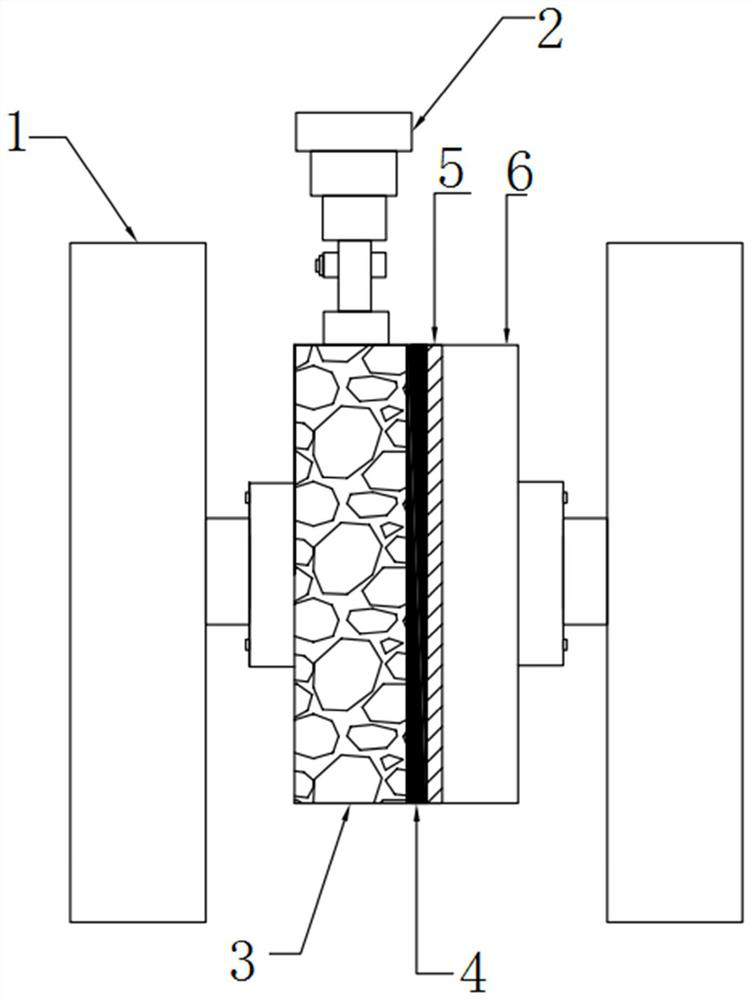

[0039] Such as figure 1 As shown, the present embodiment provides a large horizontal force shear test device for the airport pavement seal, which mainly includes a fixed frame 1, a cement concrete slab 3, an epoxy asphalt sand mist seal 4, an epoxy adhesive 5, a load Collet 2 and metal plate 6.

[0040] The epoxy adhesive 5 uses epoxy resin AB superglue, and the epoxy resin AB superglue respectively bonds and fixes the metal plate 6 and the cement concrete plate 3-epoxy asphalt sand mist seal layer 4 to form a three-layer structure specimen.

[0041] The fixed frame 1 includes left and right fixed brackets, and the left and right fixed brackets are respectively provided with fixed chucks, and the three-layer structure specimen is fixed by the left and right fixed bracket chucks of the fixed frame. Both the fixing frame 1 and the load chuck in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com