Double-sided capacitive humidity sensor and preparation method thereof

A humidity sensor, capacitive technology, applied in the sensor field, can solve the problems of humidity measurement error, low humidity sensing efficiency, limited space, etc., and achieve the effect of tolerance value adjustment range, high humidity sensitivity, and wide detection space range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

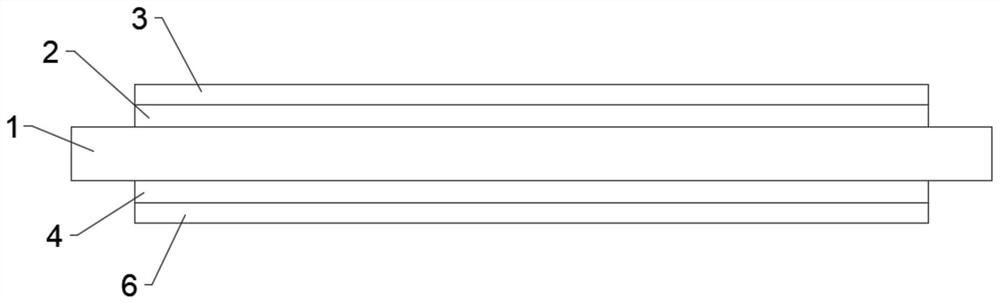

[0047] Such as figure 1 As shown, this embodiment provides a double-sided capacitive humidity sensor, including a substrate 1 , a first electrode layer 2 , a first moisture-sensing layer 3 , a second electrode layer 4 and a second moisture-sensing layer 6 .

[0048] The first electrode layer 2 and the second electrode layer 4 are respectively connected to the two sides of the substrate 1 and pasted on the two sides of the substrate 1. The first moisture-sensitive layer 3 is covered on the first electrode layer 2, and the second moisture-sensitive layer 6 covering the second electrode layer 4.

[0049] Wherein, the first electrode layer 2 and the second electrode layer 4 are interdigital electrode layers. Wherein, the areas of the first electrode layer 2 and the second electrode layer 4 and the areas of the first moisture-sensing layer 3 and the second moisture-sensing layer 6 may be the same or different, and may be specifically designed according to actual conditions. There...

Embodiment 2

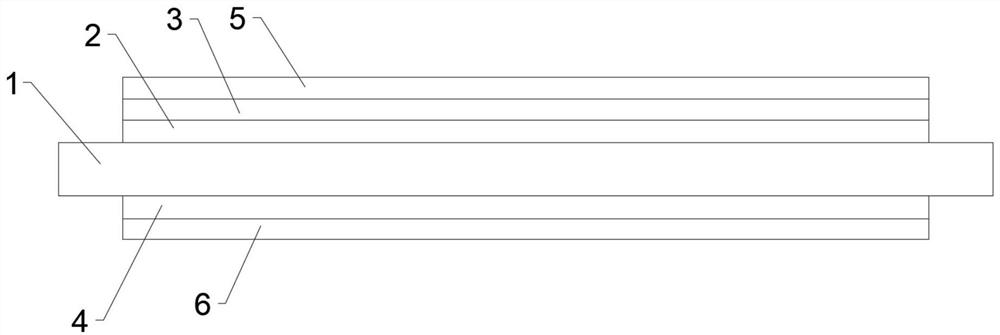

[0059] Such as figure 2 As shown, this embodiment provides a double-sided capacitive humidity sensor, including a substrate 1, a first electrode layer 2, a first moisture-sensing layer 3, a second electrode layer 4, a second moisture-sensing layer 6 and a third electrode Layer 5.

[0060] The first electrode layer 2 and the second electrode layer 4 are respectively connected to the two sides of the substrate 1 and pasted on the two sides of the substrate 1. The first moisture-sensitive layer 3 is covered on the first electrode layer 2, and the second moisture-sensitive layer 6 covering the second electrode layer 4. The third electrode layer 5 covers the first moisture-sensing layer 3 .

[0061] Wherein, the first electrode layer 2 and the second electrode layer 4 are double electrode layers. Wherein, the areas of the first electrode layer 2 and the second electrode layer 4 and the areas of the first moisture-sensing layer 3 and the second moisture-sensing layer 6 may be th...

Embodiment 3

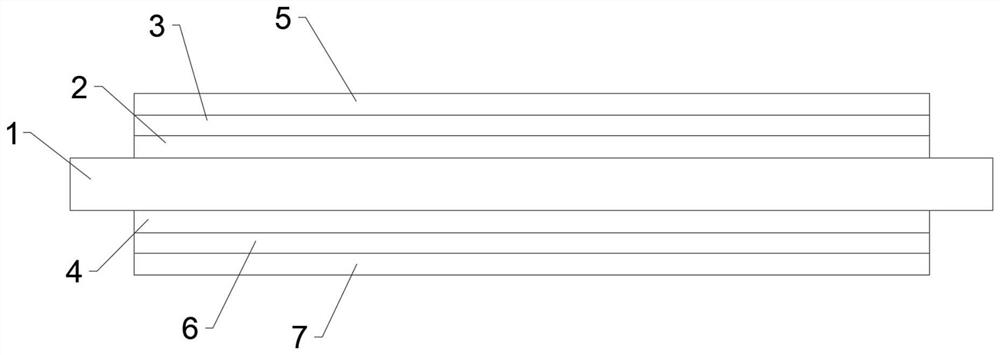

[0073] Such as figure 2 As shown, this embodiment provides a double-sided capacitive humidity sensor, including a substrate 1, a first electrode layer 2, a first moisture-sensing layer 3, a second electrode layer 4, a second moisture-sensing layer 6 and a third electrode Layer 5.

[0074] The first electrode layer 2 and the second electrode layer 4 are respectively connected to both sides of the substrate 1 , the first moisture-sensing layer 3 covers the first electrode layer 2 , and the second moisture-sensing layer 6 covers the second electrode layer 4 . The third electrode layer 5 covers the first moisture-sensing layer 3 .

[0075] Wherein, the first electrode layer 2 is a double electrode layer, and the second electrode layer 4 is an interdigital electrode layer. Wherein, the areas of the first electrode layer 2 and the second electrode layer 4 and the areas of the first moisture-sensing layer 3 and the second moisture-sensing layer 6 may be the same or different, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com