Coatable polyacrylamide hydrogel-based high-sensitivity humidity response driver and preparation method thereof

A polyacrylamide, humidity-responsive technology, applied in the field of humidity-responsive actuators, can solve the problems of high water surface tension, dehydration, and weakened driving performance, and achieve the effects of fast response speed, simple preparation, and high humidity sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation method based on coatable polyacrylamide hydrogel high sensitivity humidity response driver, which comprises the following steps:

[0030] 1) Preparation of a hydrogel coatable with polyacrylamide by free radical polymerization:

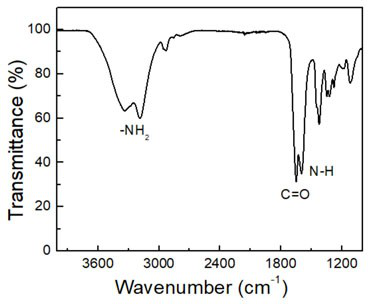

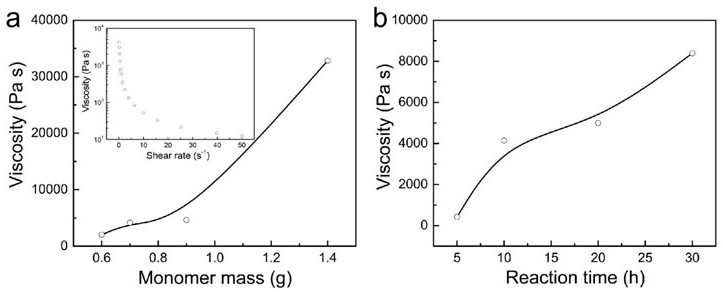

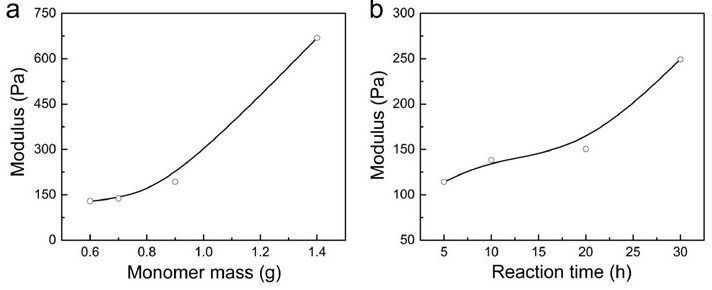

[0031] 0.75 g acrylamide monomer and 0.0035 g ammonium persulfate are added to a 9.5 mL crosslinker solution (the crosslinker solution is a homogeneously dispersed mixed solution obtained by stirring vinyl triethoxysilane in deionized water for 24 hours until the oily droplets disappear, with a mass concentration of 0.1%) and then the mixed solution is at N 2 Sealed in an atmosphere at 42 °C for 12 h, synthesized to obtain a hydrogel coatable with polyacrylamide;

[0032] 2) Preparation of a three-layer structure composite film based on polyacrylamide hydrogel, i.e., humidity response driver: the adhesion performance and water retention performance of the hydrogel are poor, based on this application, based on the invention of polyacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com