Rotary friction nanometer generator

A nano generator and generator technology, applied in the field of energy transfer and conversion, can solve the problems of easy dissipation of charge, complex electrical components and circuit design, etc., and achieve the effects of short-term effect, simple structure and method, and enhanced output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

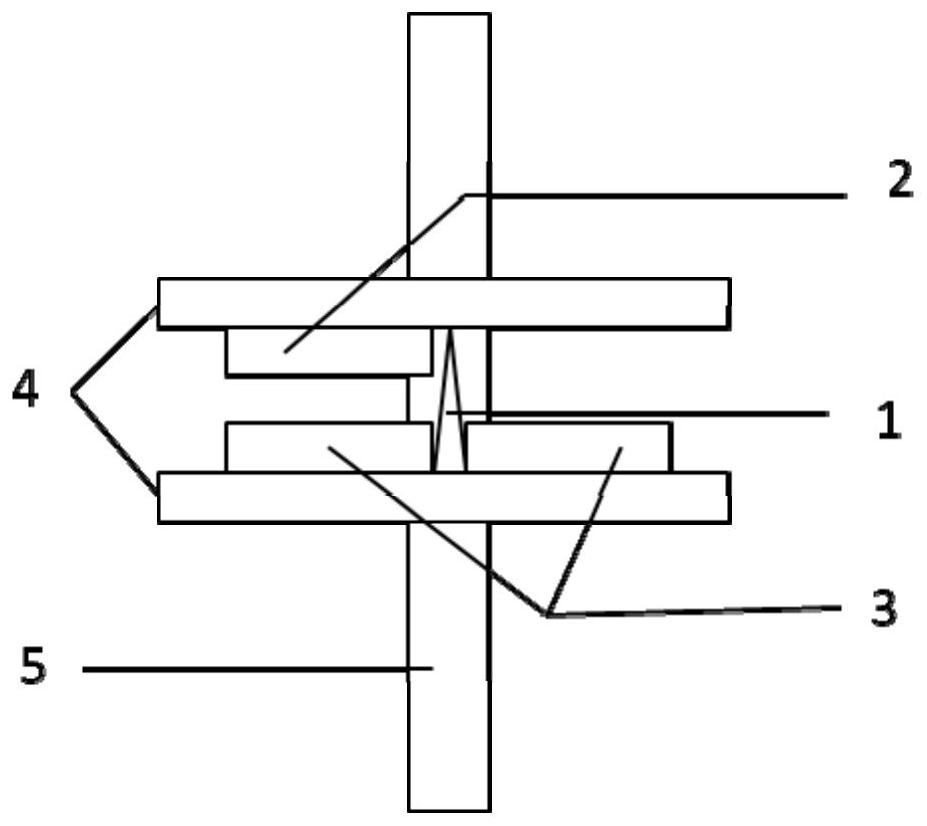

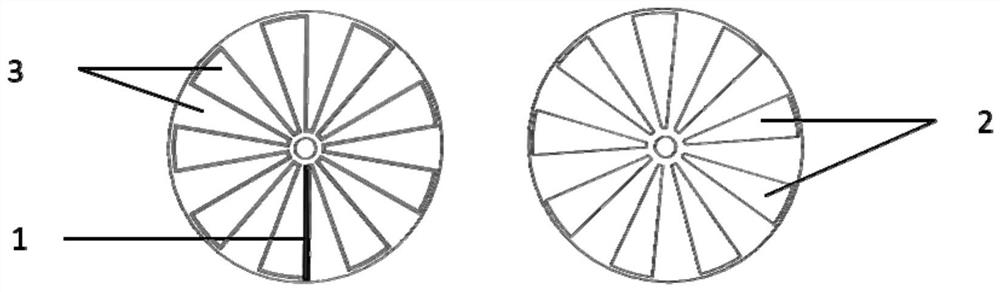

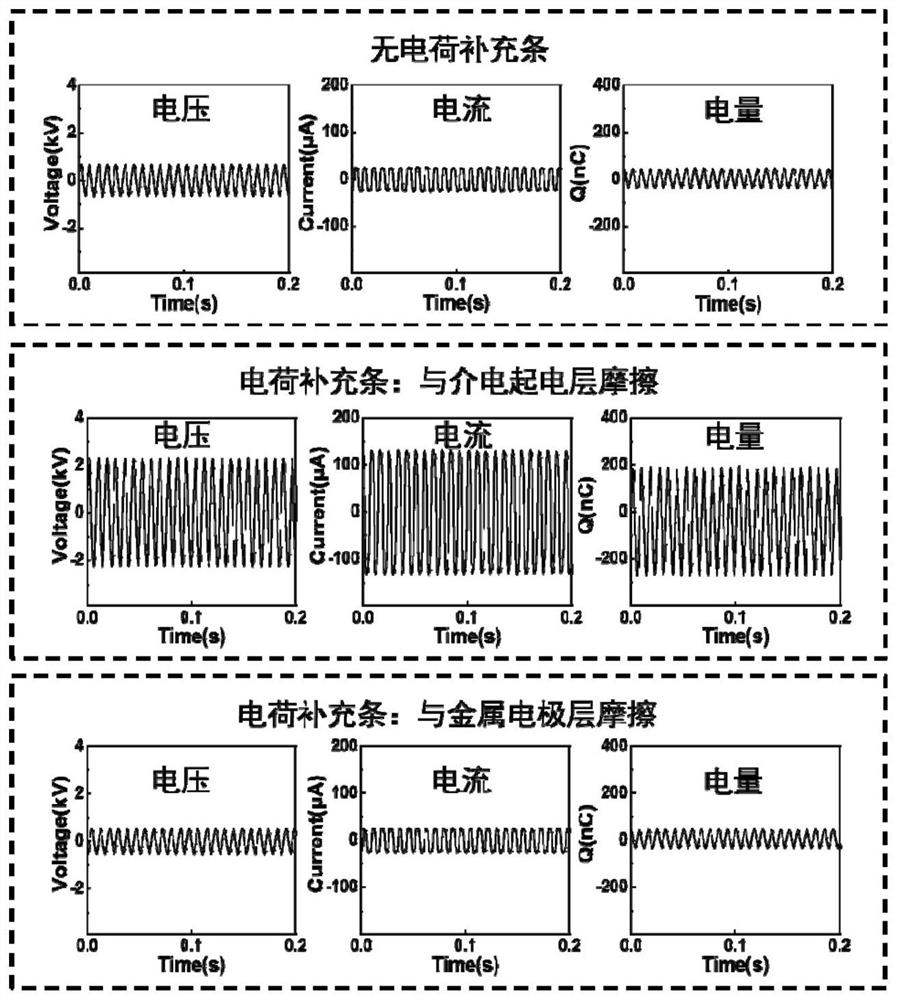

[0028] The typical structure of the rotary friction nanogenerator provided by the invention, see figure 1 , including a charge replenishment strip 1, a dielectric layer 2, and a sensing electrode layer 3, wherein the sensing electrode layer 3 includes 2N (N is an integer) electrode units arranged around the rotation axis 5, and two adjacent electrode units are not conductive to each other. Every other electrode unit is connected to each other to form two output terminals of the generator; the charge supplementary strip 1 and the sensing electrode layer 3 are set to be fixed to each other; the dielectric layer 2 and the sensing electrode layer are separated by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com