Rapid honey pressurizing and filtering equipment for bee breeding site

A filtration equipment and field technology, applied in the fields of filtration and separation, mobile filter element filters, food science, etc., can solve the problems of low natural flow filtration efficiency, inconvenience for beekeeping on-site use, affecting honey flavor, etc. The effect of reducing the blocking effect, the difficulty of maintenance and the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

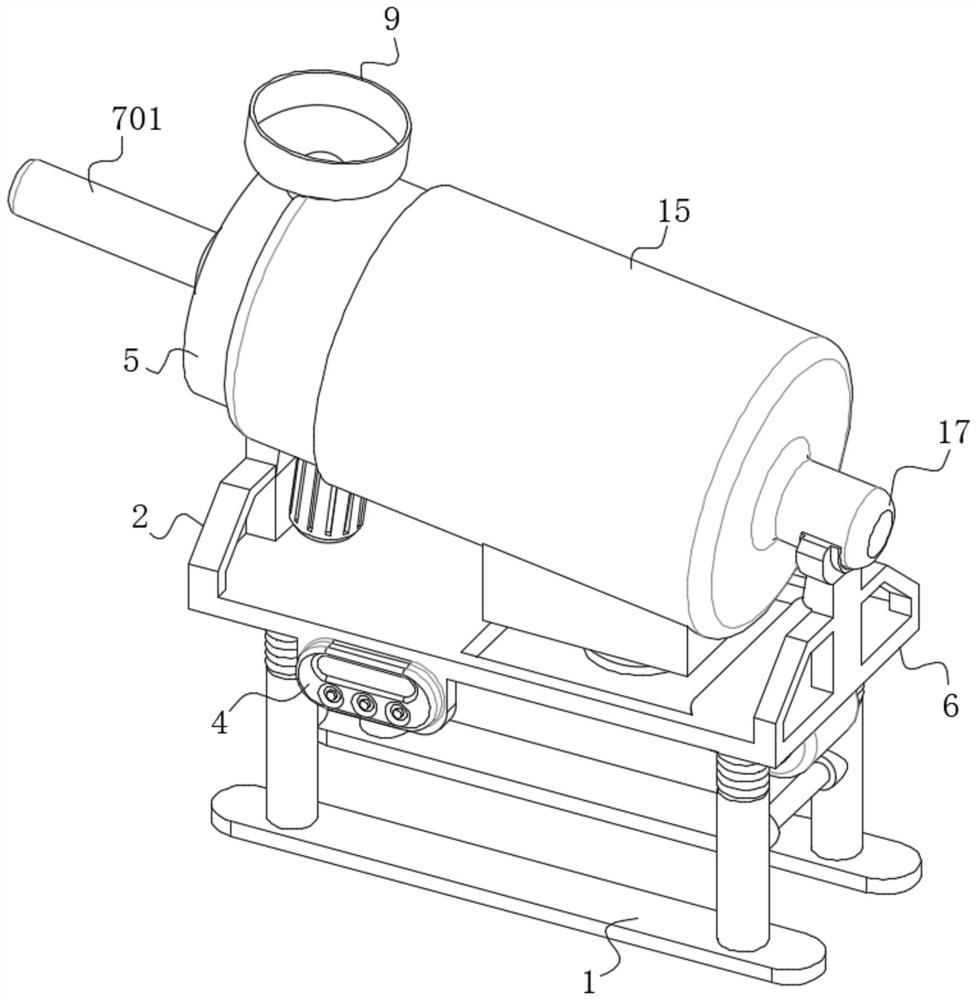

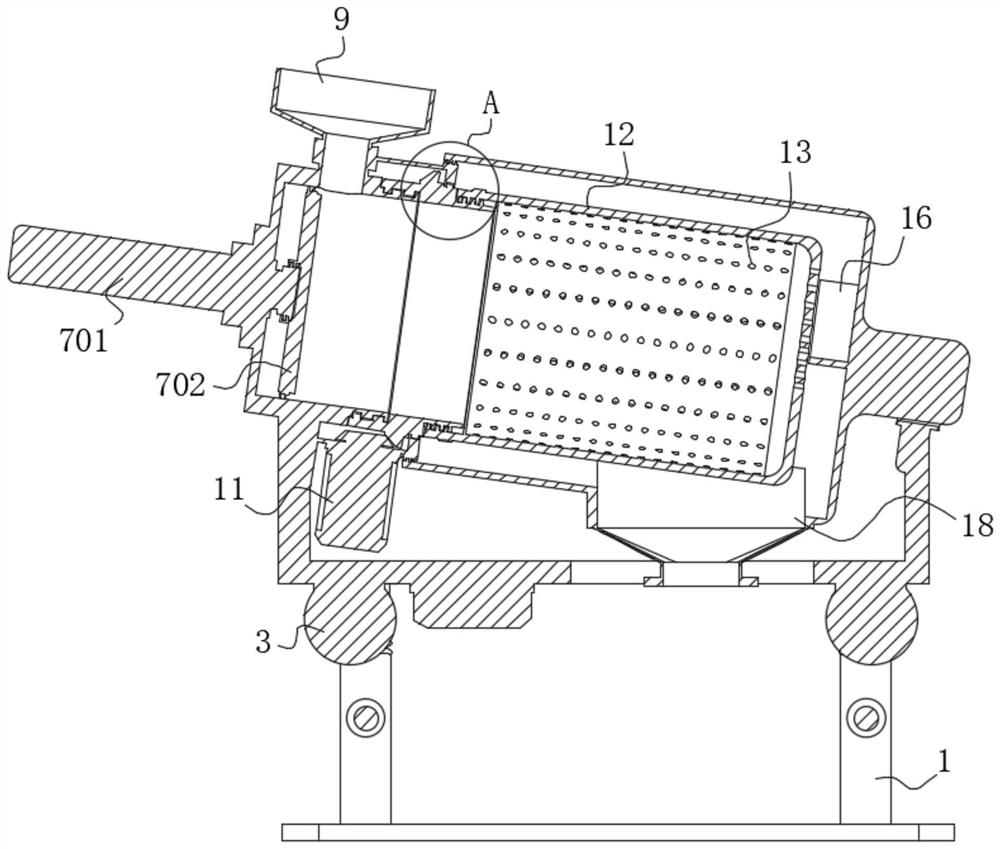

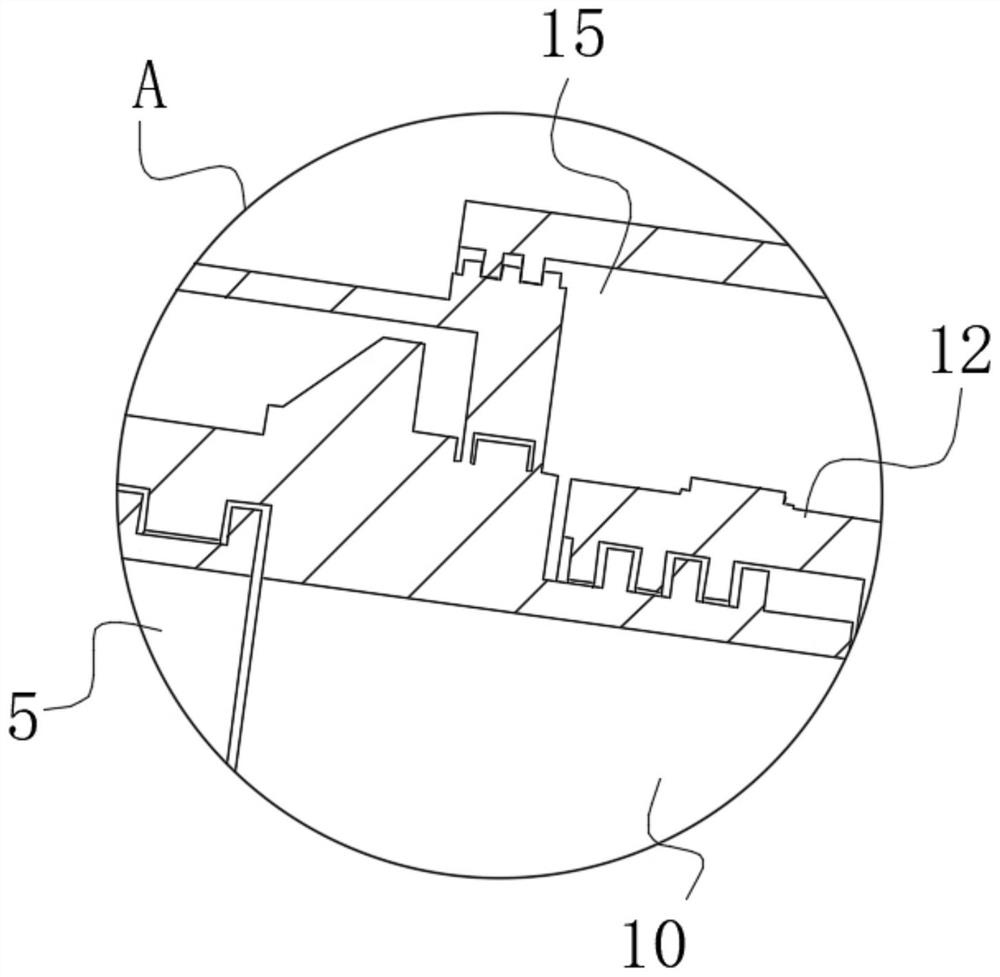

[0033] see Figure 1-7 , the present invention provides a technical solution: a rapid pressurization and filtering equipment for honey on the bee breeding site, comprising a shock absorbing support 1, the top of the shock absorbing support 1 is fixedly connected with a vibrating seat 2, and the bottom surface of the vibrating seat 2 is fixedly installed with two Symmetrically arranged vibrating motors 3, when working, the two vibrating motors 3 generate a vibration source at a set frequency, through the generation of the vibration source, thereby effectively improving the flow rate of honey during filtration and the filtered rate of honey on the filter drum 12. rate;

[0034] The bottom surface of the shock-absorbing support 1 is fixedly installed with an electric control assembly 4, and the electric control assembly 4 includes a battery and a control panel. The panel surface is fixed with a central control button;

[0035] The function of the battery setting is to provide p...

Embodiment 2

[0042] The second embodiment of the present application proposes another kind of rapid pressurization and filtering equipment for honey on the bee breeding site. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0043] The second embodiment of the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

[0044] see Figure 1-7 , the present invention provides a technical solution: a rapid pressurization and filtering equipment for honey on the bee breeding site, comprising a shock absorbing support 1, the top of the shock absorbing support 1 is fixedly connected with a vibrating seat 2, and the bottom surface of the vibrating seat 2 is fixedly installed with two Symmetrically arranged vibrating motors 3, when working, the two vibrating motors 3 generate a vibration source at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com