A panel processing device for panel furniture

A technology for panel processing and panel furniture, which is applied in the field of panel processing, can solve the problems of difficult control of grinding precision, lower grinding efficiency, and low grinding efficiency, and achieve the effects of increasing adjustment speed, improving utilization rate, and improving protection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

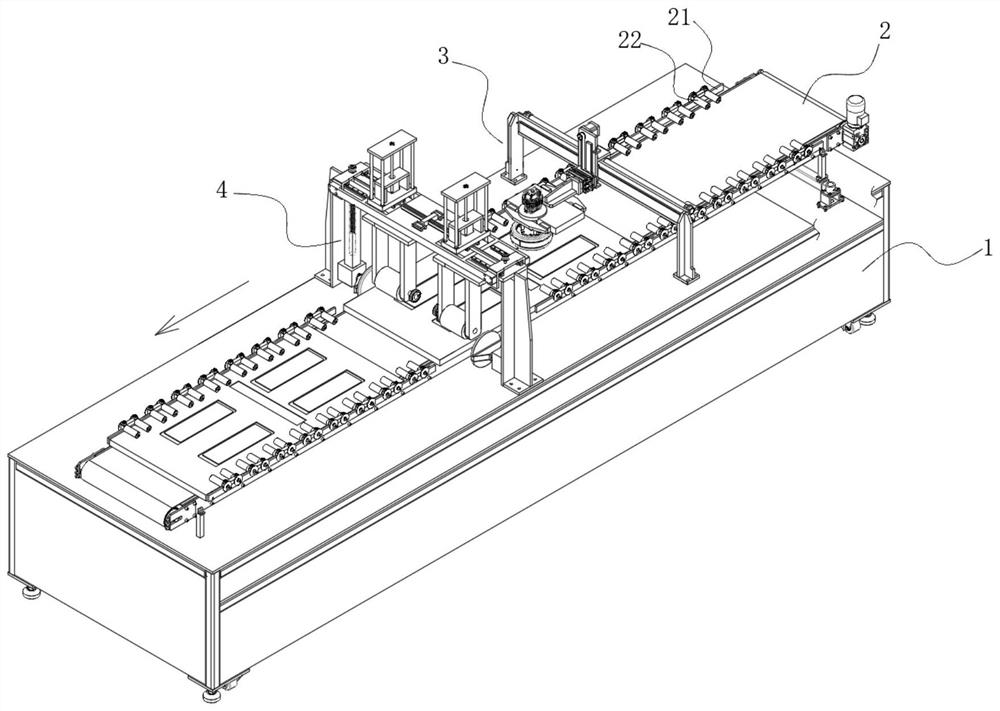

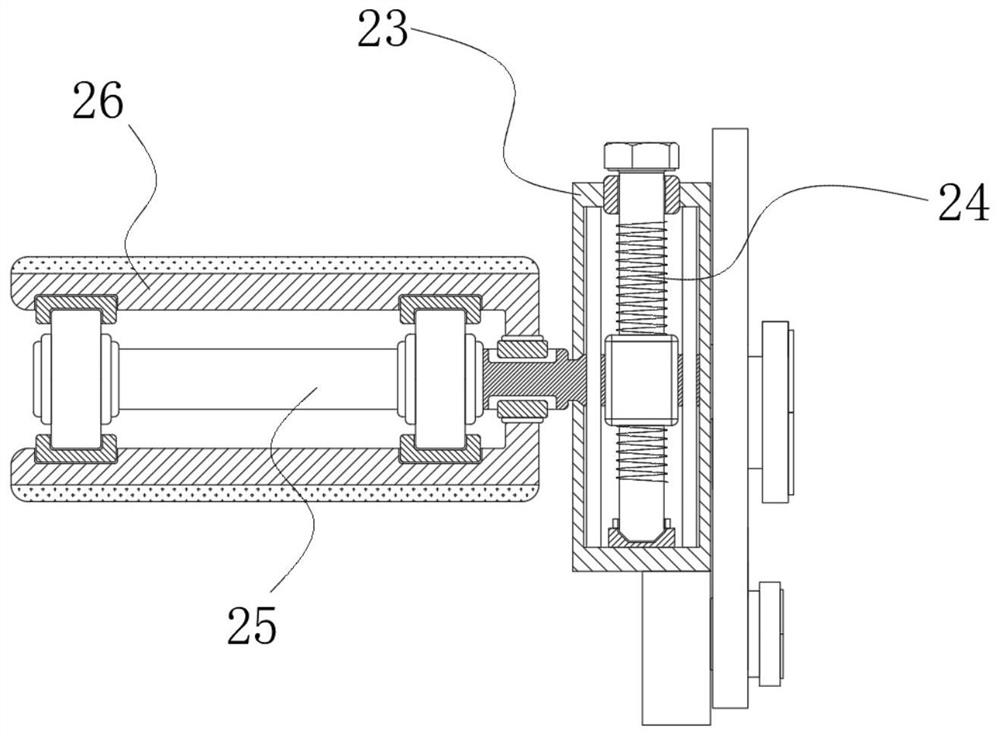

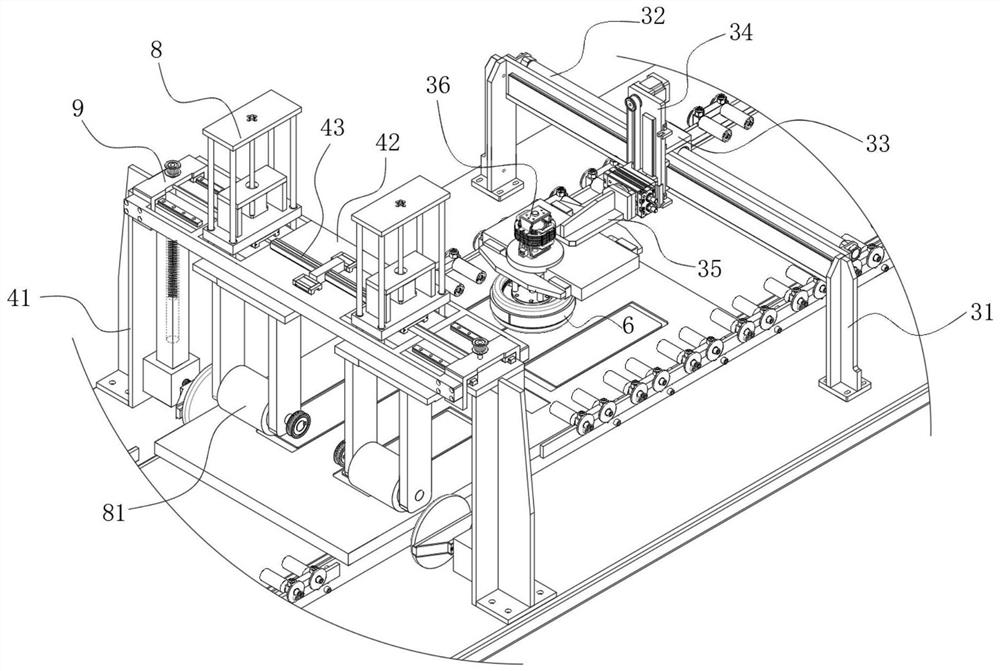

[0040] refer to figure 1 , the present invention provides a technical solution: a plate processing device for panel furniture, which includes a processing table 1, a material transfer device 2, a front grinding device 3 and a side grinding device 4, and the material transfer device 2 is arranged on the processing table 1 On the top, the plate is conveyed, the side of the material transfer device 2 is equipped with a strip splint 21, and the strip splint 21 is equipped with a rolling press 22, and a plurality of groups are arranged along the strip splint 21, and the plate carry out clamping;

[0041] The front grinding device 3 straddles the feeding device 2 and is fixed on the processing table 1 to grind the wide area of the plate;

[0042] The side grinding device 4 is arranged in parallel with the front grinding device 3, and spans the material transfer device 2 to grind the side area of the plate;

[0043] As a preferred embodiment, the width of the plate is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com