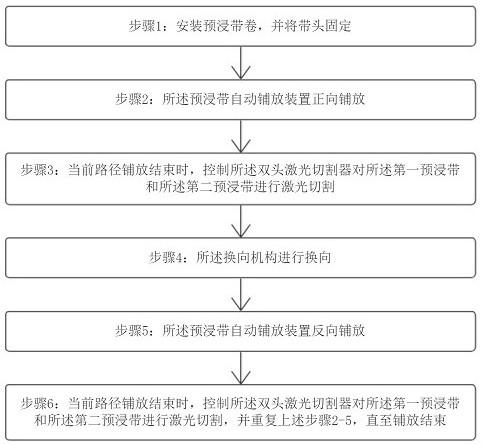

Double-layer two-way laying method of automatic prepreg tape laying device

A prepreg tape, laying technology, applied in the direction of weight reduction, etc., can solve the problems of layer-by-layer laying, low laying efficiency, adhesion and pulling on the surface of the anvil knife and the tape, so as to improve production efficiency and save laying. Laying time, ensure the effect of the laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

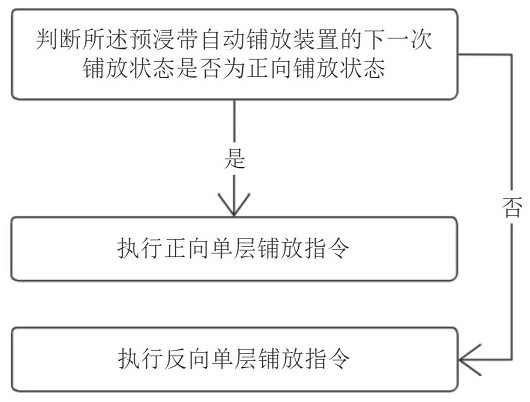

Method used

Image

Examples

Embodiment Construction

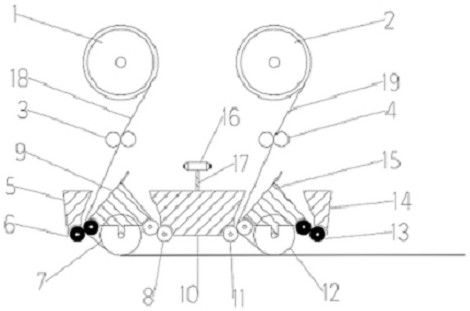

[0043] As shown in the figure: the prepreg tape automatic laying device includes a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, and the feeding mechanism includes a left tape roll 1, a right tape roll 2, a first The clamping pair of rollers 3, the second clamping pair of rollers 4, the first prepreg tape 18 and the second prepreg tape 19, the laying mechanism includes the first heating pair of rollers 6, the first pressure roller 7, the first laying Put the pair of rollers 8, the second laying pair of rollers 11, the second pressure roller 12 and the second heating pair of rollers 13, the cutting mechanism includes a double-head laser cutter 16 and a support frame 17, and the guide mechanism includes the first Guide mechanism 5, the 3rd guide mechanism 10 and the second guide mechanism 14, described reversing mechanism comprises first reversing mechanism 9 and second reversing mechanism 15, and described first revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com