Power station boiler desulfurization wastewater environment-friendly purification equipment

A technology for desulfurization wastewater and purification equipment, which is used in gaseous discharge wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve the problems of limestone mixing, uneven limestone crushing, and affecting desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

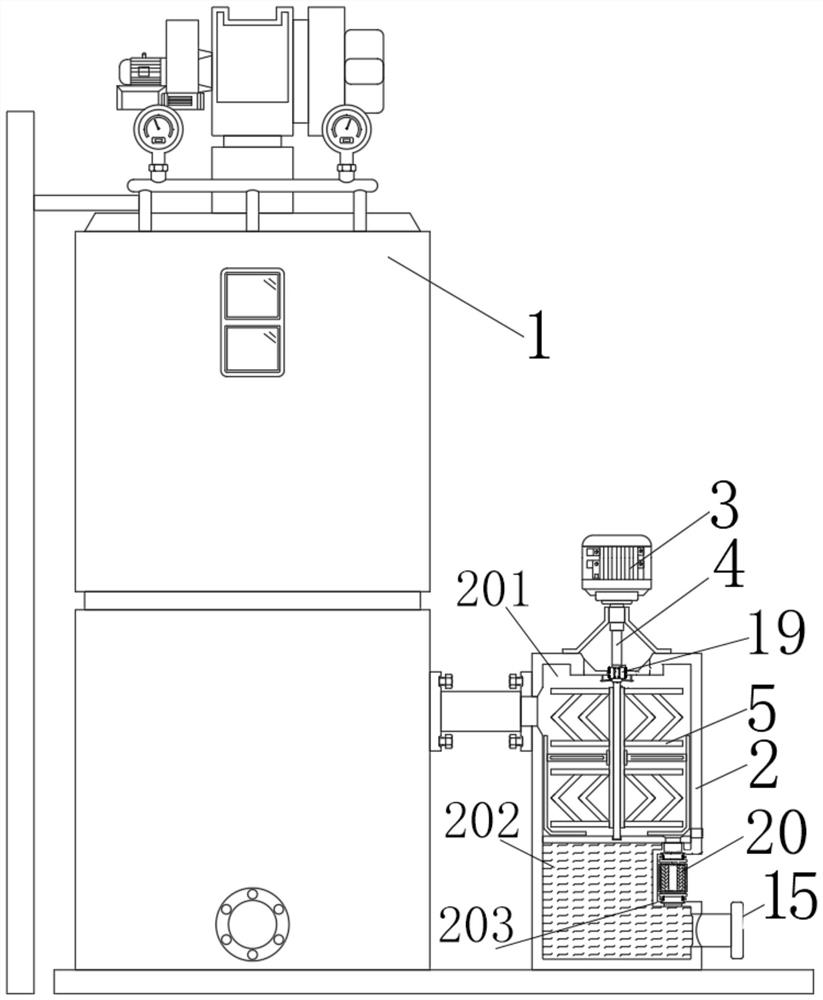

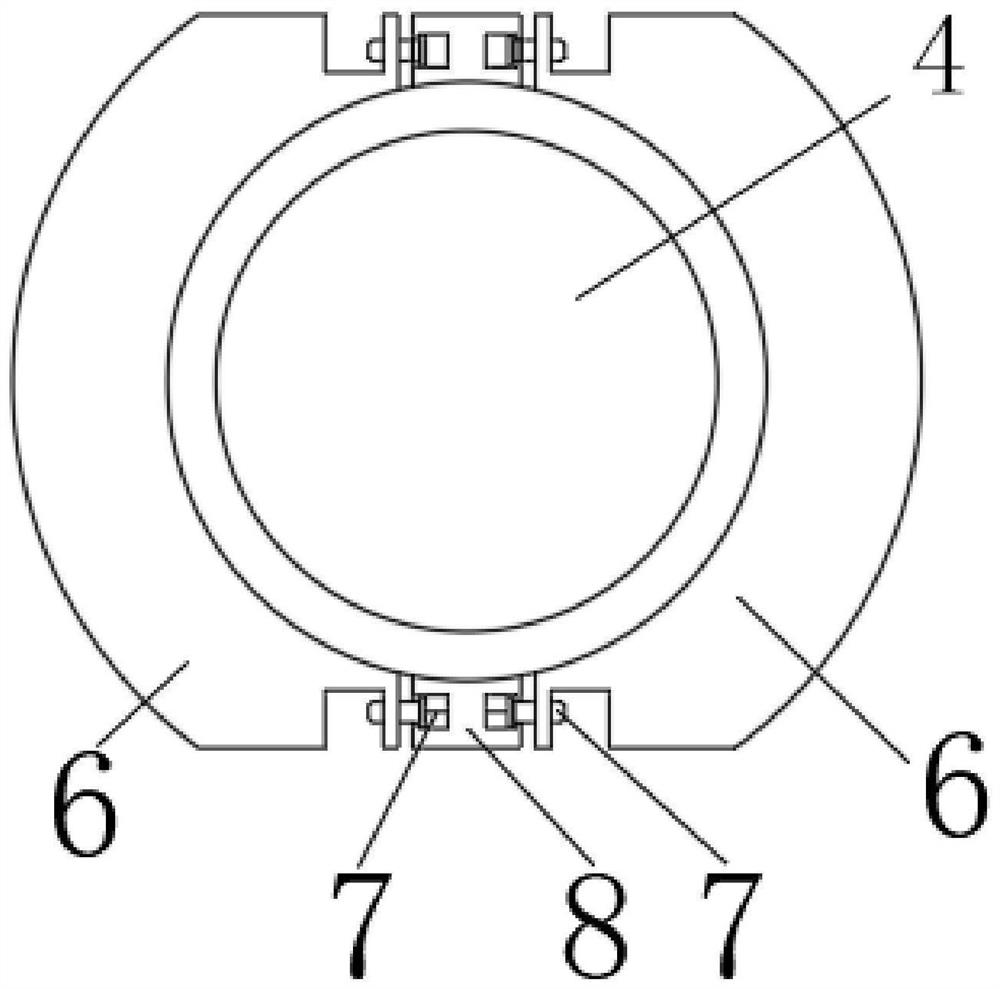

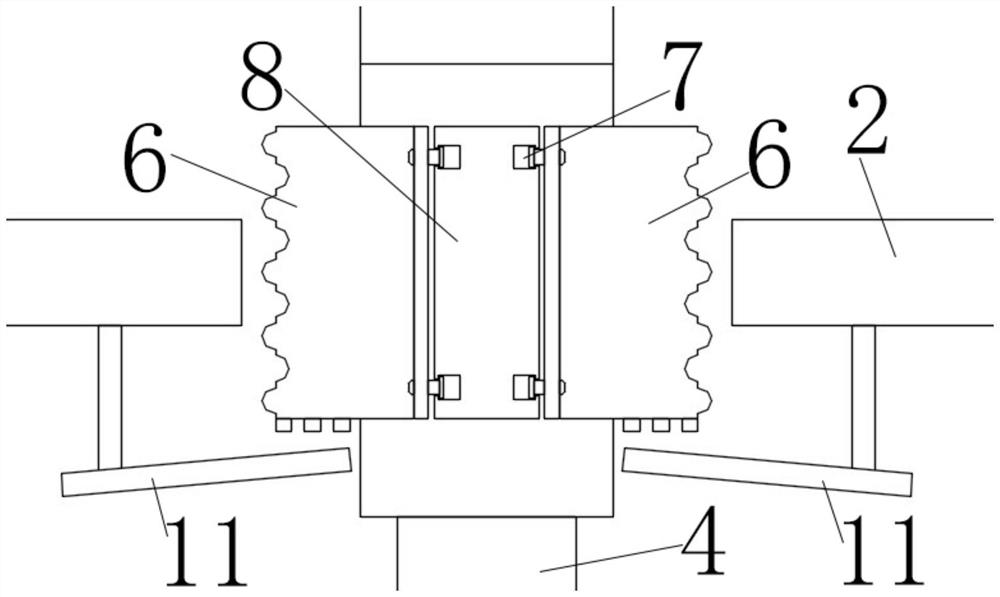

[0029] A power plant boiler desulfurization wastewater environmental protection purification equipment, such as Figure 1-5 As shown, it includes a housing 2, a servo motor 3, a transmission rod 4, a stirring rod 5, a grinding mechanism 19 and a filter assembly 20. The upper part of the housing 2 is provided with a mixing chamber 201, and the lower part of the housing 2 is provided with a drainage chamber 202. 2. A filter tank 203 is provided on the outer surface, and the filter assembly 20 is detachably installed in the filter tank 203. The water outlet of the mixing chamber 201 is connected with the water inlet of the filter assembly 20, and the water outlet of the filter assembly 20 is connected with the water inlet of the drainage chamber 202. , the servo motor 3 is erected on the top of the housing 2, and the top of the housing 2 is provided with a feed port, the output end of the servo motor 3 is fixedly connected with the transmission rod 4, and the transmission rod 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com