Production process for effectively extracting organic germanium, biological selenium and chalcone from angelica keiskei

A production process, organic germanium technology, applied in the field of Ashitaba extraction, can solve problems such as ineffective extraction and separation, failure of enrichment of selenium and germanium, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

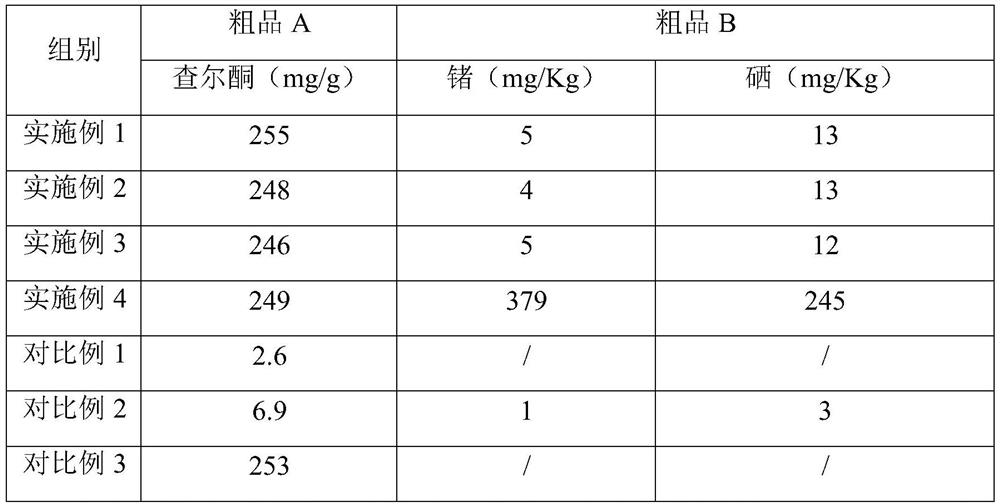

Examples

Embodiment 1

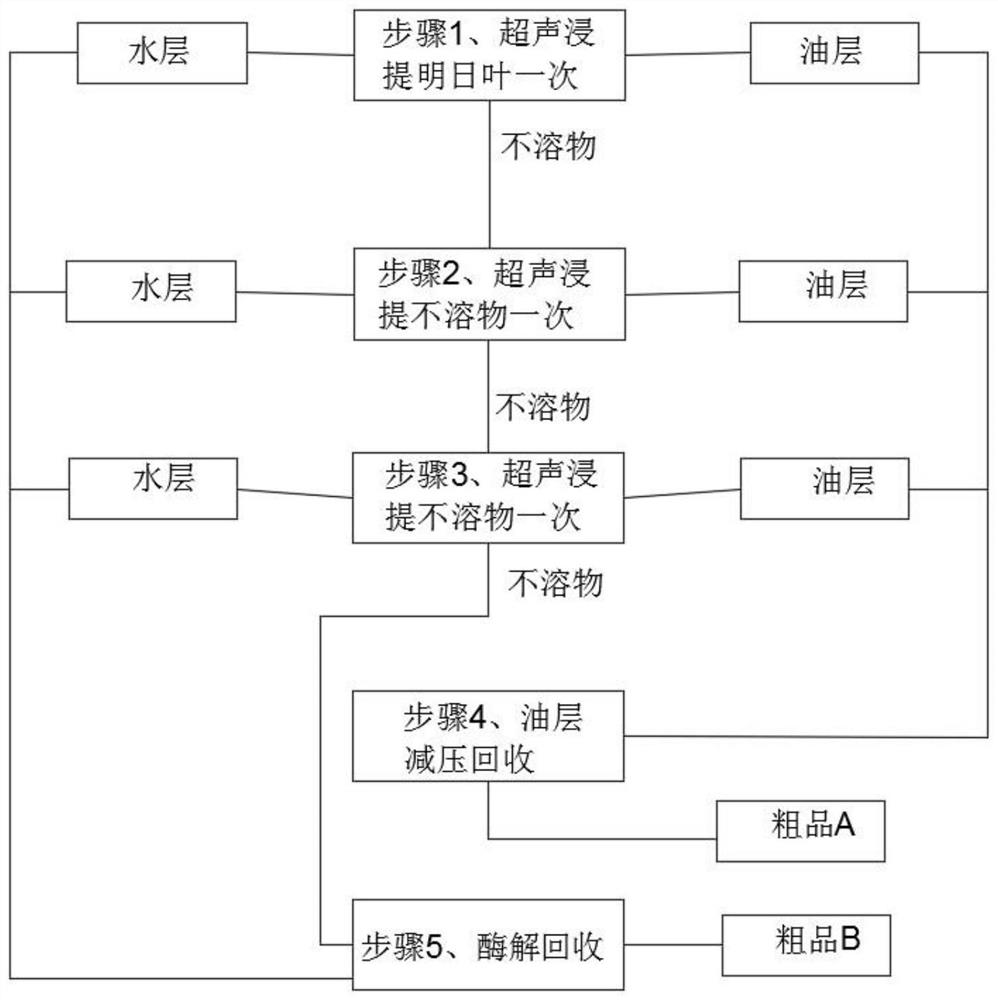

[0032] A production process for effectively extracting biological organic germanium, biological selenium and chalcone from Ashitaba, comprising the following steps:

[0033] Step 1. Ultrasonic extraction of ashitaba once

[0034] Cut the freshly picked Ashitaba leaves into chunks with a length of 0.5-1cm, extract once with chloroform that is 3 times the weight of the freshly picked Ashitaba leaves, and use ultrasonic conditions at a temperature of 30-40°C and a power of 80 Extract at -100W for 3min, filter out the insoluble matter, and separate the filtrate to obtain a water layer and an oil layer;

[0035] Step 2, Ultrasonic extraction of insoluble matter once

[0036] Put the insoluble matter in step 1 into a chloroform solution that is 3 times the weight of the freshly picked Ashitaba leaves and extract it once. Under the ultrasonic conditions, the temperature is 40-45°C, the power is 100-150W, and the extraction time is 10 minutes, and the insoluble matter is filtered out...

Embodiment 2

[0044] A production process for effectively extracting biological organic germanium, biological selenium and chalcone from Ashitaba, comprising the following steps:

[0045] Step 1. Ultrasonic extraction of ashitaba once

[0046] Cut the freshly picked Ashitaba leaves into chunks with a length of 0.5-1cm, extract once with chloroform that is 3 times the weight of the freshly picked Ashitaba leaves, and use ultrasonic conditions at a temperature of 30-40°C and a power of 80 Extract at -100W for 3min, filter out the insoluble matter, and separate the filtrate to obtain a water layer and an oil layer;

[0047] Step 2, Ultrasonic extraction of insoluble matter once

[0048] Put the insoluble matter in step 1 into a chloroform solution that is 3 times the weight of the freshly picked Ashitaba leaves and extract it once. Under the ultrasonic conditions, the temperature is 40-45°C, the power is 100-150W, and the extraction time is 10 minutes, and the insoluble matter is filtered out...

Embodiment 3

[0056] A production process for effectively extracting biological organic germanium, biological selenium and chalcone from Ashitaba, comprising the following steps:

[0057] Step 1, Ultrasonic Extraction of Ashitaba once Cut the freshly picked Ashitaba leaves into chunks with a length of 0.5-1cm, and use 3 times the weight of freshly picked Ashitaba leaves to extract once with chloroform, under ultrasonic conditions Extract at a temperature of 30-40°C and a power of 80-100W for 3 minutes, filter out the insoluble matter, and separate the filtrate to obtain a water layer and an oil layer;

[0058] Step 2. Ultrasonic extraction of insoluble matter once. Put the insoluble matter in step 1 into a chloroform solution that is 3 times the weight of freshly picked Ashitaba leaves and extract once. Under the ultrasonic conditions, the temperature is 40-45°C, and the power is 100- 150W, leaching for 10min, filtering out the insoluble matter, separating the filtrate to obtain a water lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com